Silicon Cell

4.2.1 Silicon cells Silicon is the most popular material in commercial solar cell modules, accounting for about 90% of the photovoltaic cell market. This success is due to several

11 Best Solar Panel Manufacturers

Aug 25, 2024 · JA Solar offers a range of monocrystalline and polycrystalline silicon solar panels with efficiencies typically ranging from 16% to 22%. Their

Crystalline Silicon Photovoltaics Research

3 days ago · The U.S. Department of Energy (DOE) Solar Energy Technologies Office (SETO) supports crystalline silicon photovoltaic (PV) research and

China Polycrystalline Silicon Photovoltaic Panels Manufacturers

ORITRON is one of the most professional polycrystalline silicon photovoltaic panels manufacturers and suppliers in China. If you''re going to buy high quality polycrystalline silicon

Top 11 Solar Panel Manufacturers in China :

Nov 30, 2024 · JA Solar offers a broad range of solar products, including silicon wafers, solar cells, and photovoltaic modules. The company''s modules are

Polycrystalline Silicon Photovoltaic Module manufacturers

Manufacturer/Factory Contact Now Inquiry Basket 1 / 6 Favorites 400W Monocrystalline Solar Cell Solar Panels 5bb 48V 96 Solar Cell 500 Watt PV Module US$ 0.22-0.3 / W (FOB Price) 10 W

Environmental impact of monocrystalline silicon photovoltaic modules

Jun 30, 2025 · The environmental impact mainly relates to freshwater desalination, fossil resource scarcity, and ozone formation. The key processes are the extraction of polycrystalline silicon,

The difference between monocrystalline silicon

May 24, 2024 · Polycrystalline silicon is a polycrystalline material composed of a large number of small crystals, with a wide range of applications, mainly

Polycrystalline Photovoltaic Cell Manufacturers in the World

Polycrystalline Photovoltaic Cell Manufacturers in the World.Tianwei New Energy Holdings Co., Ltd. TWNE engages in the entire value chain of the solar photovoltaic (PV) industry -- the

Solar Cell Production: from silicon wafer to cell

Aug 17, 2023 · Producers of solar cells from silicon wafers, which basically refers to the limited quantity of solar PV module manufacturers with their own wafer

Polycrystalline solar cells: Part of the most

Buy polycrystalline solar modules Depending on the budget and the area available, a module made of polycrystalline solar cells is the right photovoltaic

Monocrystalline Silicon Cell

Monocrystalline silicon cells are defined as photovoltaic cells produced from single silicon crystals using the Czochralski method, characterized by their high efficiency of 16 to 24%, dark colors,

Crystalline Silicon Photovoltaic Module Manufacturing

Feb 10, 2020 · Polycrystalline silicon or "polysilicon" is the feedstock used to make monocrystalline- or multicrystalline-silicon ingots, which are then sliced into wafers, fabricated

Solar Panel Manufacturing Process: Step-by-Step Guide

Apr 12, 2025 · Complete solar panel manufacturing process – from raw materials to a fully functional solar panel. Learn how solar panels are made in a solar manufacturing plant,

Top 10 Global Solar Cell Manufacturers by 2025:

Mar 21, 2025 · Discover the top 10 global solar cell manufacturers leading the renewable energy revolution in 2025. Explore key players, market trends,

Monocrystalline silicon: efficiency and

Sep 3, 2018 · Better photon absorption due to its black color, compared to the characteristic blue tone of poly-silicon. Monocrystalline cells are more

Solar Manufacturing Cost Analysis | Solar Market

Aug 7, 2025 · Solar Manufacturing Cost Analysis NREL analyzes manufacturing costs associated with photovoltaic (PV) cell and module technologies and

Advances in crystalline silicon solar cell technology for

Jul 22, 2010 · Various technologies for mono- and polycrystalline PV cells are compared and discussed with respect to the corresponding material technologies, such as silicon ingot and

Top 10 crystalline PV module manufacturer

Jul 20, 2018 · With production and capacity figures provided by industry analyst IHS Markit, pv magazine provides a rundown of the top 10 crystalline silicon

Energy Production and Performance of Polycrystalline

Aug 23, 2013 · Six polycrystalline silicon photovoltaic modules—two apiece from three manufacturers—were simultaneously deployed outdoors on the performance and energy

Module

"First-generation PV" refers to crystalline silicon PV technology, of which the two most common types are monocrystalline silicon PV cells (mono c-Si) and

Photovoltaic Module Manufacturers in Canada

Product types: photovoltaic modules, solar electric power systems, photovoltaic systems commercial, photovoltaic systems residential, photovoltaic cells thin film amorphous silicon,

Polycrystalline silicon photovoltaic module, Polycrystalline

Find your polycrystalline silicon photovoltaic module easily amongst the 51 products from the leading brands (, Bosch, Akcome,) on DirectIndustry, the industry specialist for your

Polycrystalline Solar Panel: Features, Working

Jun 15, 2024 · Follow this new blog in Linquip to learn more about this type of solar panel. What is a polycrystalline solar panel? Polycrystalline or multi

Polycrystalline Silicon Pv Cell

China Polycrystalline Silicon Pv Cell wholesale - Select 2024 high quality Polycrystalline Silicon Pv Cell products in best price from certified Chinese Solar Cell Panel Charger manufacturers,

Polysilicon Manufacturers: Global Top 10

Who are the world''s top 10 polysilicon manufacturers? ⭐ How far have China''s largest producers caught up? ️ Get the ranking now!

Polycrystalline Solar Panel Specifications

Nov 17, 2023 · The surface of these solar cells resembles a mosaic which comes under polycrystalline solar panel specifications. These solar panels are square

What you need to know about polysilicon and

Oct 13, 2021 · Polysilicon, a high-purity form of silicon, is a key raw material in the solar photovoltaic (PV) supply chain. To produce solar modules, polysilicon is

Polycrystalline Full Cell PV Module | M2

Nov 16, 2024 · Poly Crystalline PV modules utilize polycrystalline silicon cells to convert sunlight into electricity. The M2 PIX P2 72 model is engineered with

Mono Solar Cells for PV Manufacturers | Targray

2 days ago · Our high-efficiency mono solar cells are made with best-in-class PV materials to help solar module manufacturers and suppliers enhance their cost

6 FAQs about [Manufacturers of polycrystalline silicon photovoltaic cell modules]

What is raw polycrystalline silicon?

Raw polycrystalline silicon, commonly referred to as polysilicon, is a high-purity form of silicon which serves as an essential material component in the solar photovoltaic (PV) manufacturing industry. It is the primary feedstock material used for the production of solar cells today.

How many companies are involved in polycrystalline panel production?

Companies involved in polycrystalline panel production. 1,227 polycrystalline panel manufacturers are listed below.

Where are solar panels made?

The seventh-largest solar manufacturer is the only solar panel manufacturer on this list to have its main headquarters outside China. Canadian Solar has more than 20,000 employees in dozens of countries, as well as manufacturing facilities in Canada, the US, Brazil, and across Asia.

What material is used for solar cell production?

It is the primary feedstock material used for the production of solar cells today. Polysilicon feedstock generally consists of large rods which are broken into chunks or chips of various size, then cast into multicrystalline ingots. The ingot materials are subsequently sliced into silicon wafers suitable for solar cell production.

Where are Trina Solar panels made?

As well as making panels, storage batteries, and trackers, Trina has also built large-scale solar installations in China, Japan, Vietnam, Australia, Chile, Mexico, the US, Greece – and two solar farms in the UK. Between 2020 and 2022, Trina also achieved a 62% reduction in the carbon emissions that come from producing its solar panels.

Why do we supply polysilicon materials (polycrystalline silicon)?

We supply polysilicon materials (polycrystalline silicon) to meet the commercial needs of solar PV manufacturers in markets around the world.

Industry Information

- Energy storage inverter can be connected to the grid

- Guinea s telecommunications base station battery energy storage system begins construction

- Bess system for solar factory in Chad

- Uninterruptible power supply for Djibouti electricity

- The communication base station battery can be converted to 220v

- One-stop procurement solution for energy storage fire protection

- Investment ratio of energy storage system 4s

- Lithium battery station cabinet team

- Nader circuit breaker factory in Netherlands

- How much does a 90 watt solar light cost

- What are the large household energy storage batteries

- 1000W solar panel large capacity

- Iraq photovoltaic folding container house wholesale

- USA New York household off-grid energy storage power station

- Best high quality 5kw solar system supplier

- Nicaragua solar fan prices

- How big a solar panel is needed for 60 kilowatts

- The reason why Tonga does not use base station communication

- 9660 lithium battery pack price

- Iceland 30W solar street light

- German energy storage battery companies

- EK buys UPS uninterruptible power supply

- Battery Energy Storage Box Introduction

Commercial & Industrial Solar Storage Market Growth

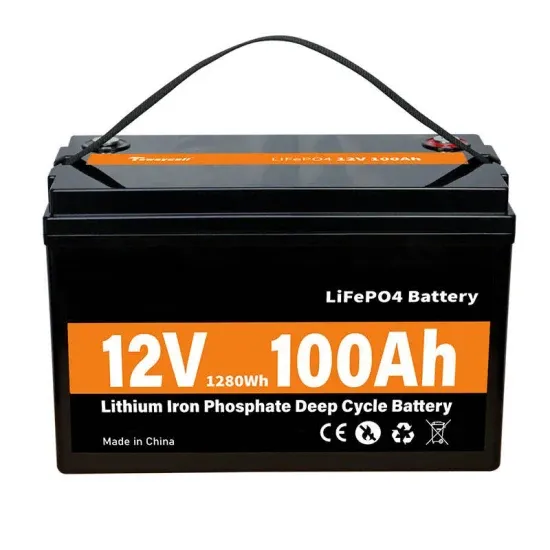

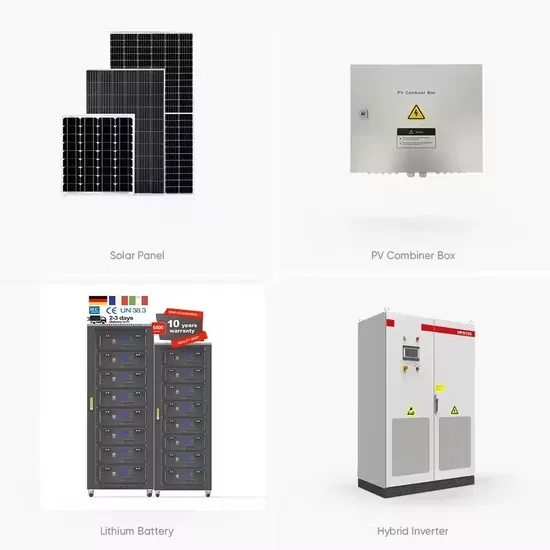

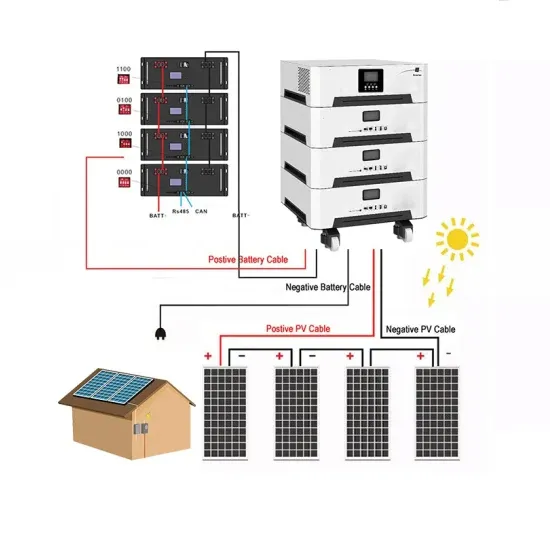

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.