Battery Rack | External Battery Racks | Battery

Jul 23, 2023 · Explore the best battery racks and cabinets for power system reliability. Learn how they help store, organize and secure batteries in

Frontiers | A Collaborative Design and Modularized

Apr 4, 2022 · Battery thermal runaway spreading mechanism, efficient thermal barrier materials and technologies are proposed, which improves battery active safety from thermal spreading

Advanced New Energy Lithium Battery PACK

Discover the state-of-the-art automated assembly production line system for lithium battery packs, designed for new energy applications. This 16-meter

Battery Cabinets

The Battery cabinet is designed to house standard VRLA Batteries of capacity range from 24Ah to 105Ah (C10). The battery cabinets are available in 5

AZE BESS Cabinets

AZE''s all-in-one IP55 outdoor battery cabinet system with DC48V/1500W air conditioner is a compact and flexible ESS based on the characteristics of

How AZE Systems Manufactures BESS Battery Energy Storage Cabinets

Feb 21, 2025 · Manufacturing a Battery Energy Storage System (BESS) cabinet is a complex process that involves designing, engineering, and assembling a robust and reliable system to

Innovating battery assembly

Aug 13, 2025 · The new servo-driven magazine technology doesn''t need feeding hoses resulting in reduced air and energy consumption while increasing the assembly productivity and flexibility.

Battery Energy Storage Cabinet Construction Process: From

Remember that Texas freeze in 2021? Storage systems that survived shared three features: heated cabinets, triple-sealed enclosures, and enough insulation to make a Yeti jealous. Now,

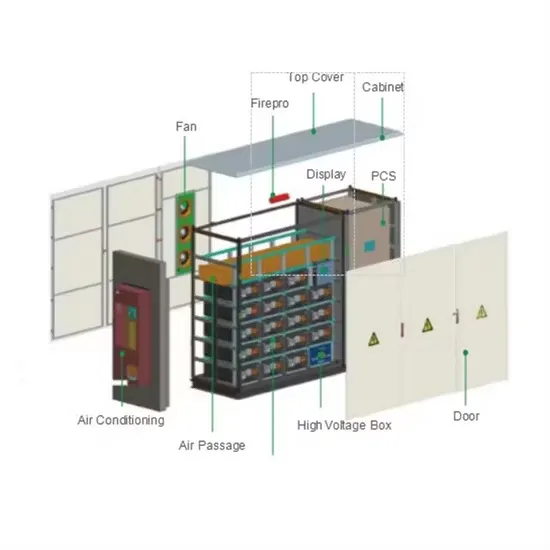

New Energy Storage Cabinet Assembly Diagram: A Step-by

Mar 26, 2022 · If you''ve ever tried assembling IKEA furniture without the manual, you''ll understand why clear assembly diagrams matter for new energy storage cabinets. This guide

Production Line Guide | CHISAGE Battery Pack

Sep 14, 2023 · Introduction: Due to the instability of photovoltaic power generation, energy storage battery Pack, as an efficient and flexible power

Battery Energy Storage System Cooling

Kooltronic offers innovative cooling solutions for battery cabinets and electrical enclosures used in renewable energy storage systems. Click to learn more.

Uninterruptible Power Supply (UPS) Backup

2 days ago · Battery Cabinets Arimon designs and manufactures custom uninterruptible power supply (UPS) backup battery cabinets, battery racks and

battery cabinet,battery storage cabinet,battery

EverExceed VRL A battery assembly cabinets are very durable, and easy to install. Engineered for use with most type of battery terminal models, these

Lithium-Ion Battery Cabinets Market

Advancements in battery chemistry, such as solid-state or sodium-ion batteries, threaten to make existing lithium-ion cabinet designs obsolete. Manufacturers investing in proprietary systems

Frontiers | A Collaborative Design and

Apr 4, 2022 · The host can be deployed in a separate cabinet. The second-level control and the third-level control correspond to the battery clusters and

C & D Technologies | Stationary Battery Cabinets

C&D battery cabinets and enclosures Battery cabinet solutions for pure lead agm batteries From the industry leader in data center backup batteries, C&D now

Assembly diagram of lithium battery energy storage

A range of outdoor energy storage battery cabinets and outdoor lithium battery cabinets are available in standard and custom configurations, can be pole-mounted or ground-mounted .

Battery Module: Manufacturing, Assembly and

Dec 28, 2022 · In the Previous article, we saw the first three parts of the Battery Pack Manufacturing process: Electrode Manufacturing, Cell Assembly, Cell

New Technologies Improve Options for Cost

4 days ago · Figure 1 – New technologies to improve cost-efficiency for batteries using prismatic cells. This article provides a brief overview of the different cell

EV Battery Technology: What''s Coming Now,

Sep 24, 2024 · A look at the novel chemistries, pack strategies, and battery types that will power electric vehicles in the months, years, and decades ahead.

Mastering the Battery Pack Assembly Process: A

Jan 23, 2025 · Conclusion The battery pack assembly process is a sophisticated and highly specialized field that underpins the success of modern energy

(PDF) BATTERY MODULE AND PACK ASSEMBLY

Feb 6, 2019 · Our second brochure on the subject "Assembly process of a battery module and battery pack" deals with both battery module assembly and

2025 Battery Roadmaps

Jan 20, 2025 · A look at the 2025 Battery Roadmaps, perhaps closer to describe this as a start of 2025 review of the latest battery roadmaps.

Case Study– Battery Cabinet Application: Energy

Mar 31, 2023 · Our battery cabinet is crafted for seamless assembly and disassembly, ensuring ease of use and maintenance. The cabinet''s thickness

Lithium-Ion Battery Assembly Process & Key

May 17, 2025 · Discover the key stages in the lithium-ion battery assembly process, from raw materials to pack assembly. Learn how battery-making

ESS Battery Cell Performance Testing Cabinet-Huiyao Laser Technology

ESS Battery Cell Performance Testing Cabinet Brief Description The ESS Battery Cell Performance Testing Cabinet is a high-precision system designed to evaluate the electrical

Home

Semco Infratech provides cutting-edge lithium-ion battery assembly solutions and holds expertise in other industries as well. In battery technology, Semco

Understanding the Battery Cell Assembly Process

Nov 11, 2023 · The world has been rapidly moving towards renewable energy sources, and batteries have emerged as a crucial technology for this

Lithium Battery Module Pack Assembly Line

In the rapidly evolving electric vehicle (EV) and energy storage markets, the Lithium Battery Module Pack Assembly Line plays a pivotal role in ensuring high-efficiency, safety, and

New UL Standard Published: UL 1487, Battery Containment

2 days ago · Learn about the first edition of UL 1487, the Standard for Battery Containment Enclosures, a binational standard for the United States and Canada published by UL

Mastering the Battery Pack Assembly Process: A

Jan 23, 2025 · What is the Battery Pack Assembly Process? The battery pack assembly process is a meticulously planned sequence of steps that

Battery integrated cabinet assembly tutorial diagram

The outdoor integrated cabinet is uesd in small capacity base stations, equipment and battery integrated cabinets can be used. The equipment put at the upper layer and the battery put

6 FAQs about [New technology for battery cabinet assembly]

Why is battery pack assembly important?

The significance of the battery pack assembly process lies in its direct impact on the performance and safety of the final product. A well-assembled battery pack ensures optimal energy storage, efficient power delivery, and long-term durability.

What is battery pack assembly process?

Battery Pack Assembly Process Component Preparation: High-quality battery cells, BMS, wiring, and casings are inspected and prepared for assembly. Cell Assembly: Battery cells are arranged in series or parallel configurations to achieve the required voltage and capacity.

Why do batteries need to be reprogrammed?

Irregularities such as part tolerances, position deviations, or contaminations tend to complicate the process. Any error in this process step can damage the battery’s exterior, lead to weak joints, harm the sensitive cells, and lead to dangerous short circuits afecting the performance and the overall safety of the battery.

How does a battery tray assembly work?

The battery tray assembly consists of several production steps. Depending on the battery design and manufacturing processes, manual tightening with bolt positioning and process control, or flow drill fastening with K-Flow technology can bring the needed process quality, productivity and flexibility.

How do you assemble a battery pack?

Assembling a battery pack involves several critical steps to ensure its performance and safety: The first step involves gathering and inspecting all necessary components, such as battery cells, the Battery Management System (BMS), wiring, connectors, and casings. This ensures that only high-quality, defect-free parts are used.

What is a battery manufacturing process?

It begins with the procurement of high-quality materials, including battery cells, BMS, wiring, and protective casings. These components are then assembled in a controlled environment to ensure precision and safety.

Industry Information

- What is the price of Cuba s special energy storage battery

- How much is the appropriate price for installing a battery cabinet

- Skopje inverter agency price range

- Price Standards for Unloading Premiums of Energy Storage Power Stations

- Bahrain 40-foot energy storage container

- Vietnam Ho Chi Minh Industrial and Commercial Photovoltaic Folding Container Wholesale

- What is grid-level energy storage

- Composition of large wind power generation system

- Small power station with generator

- Sucre lithium battery pack price

- Energy storage charging pile lithium battery

- 80W 40Ah Solar

- High quality wholesale 37 5kva transformer exporter

- Bern Power Battery BMS Standard

- Photovoltaic solar panels 15 degrees a day

- Implementation of energy storage system construction subsidies

- Is bifacial photovoltaic panel useful for power generation

- Kabul Energy Storage Power Purchase EK

- Thimphu lithium energy storage system

- Inverter 60v1600w

- Orientation of rooftop photovoltaic panels

- Georgetown inverter 12v to 220v

- Will the power outage affect 5g base stations

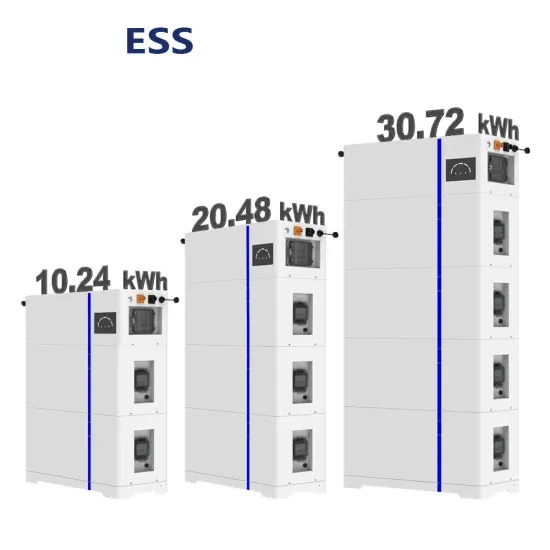

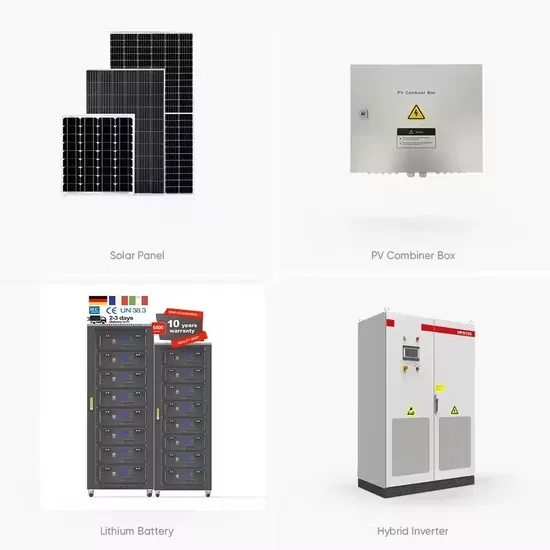

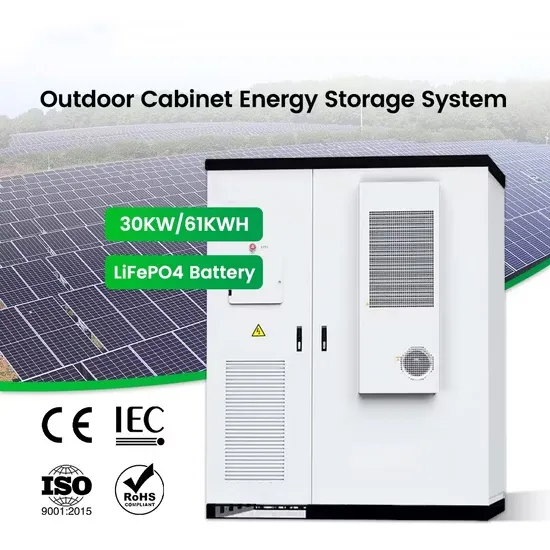

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.