(PDF) BATTERY MODULE AND PACK ASSEMBLY

Feb 6, 2019 · Our second brochure on the subject "Assembly process of a battery module and battery pack" deals with both battery module assembly and

EV Lithium Battery Production 101 | Bonnen

Sep 3, 2024 · Explore EV battery production with Bonnen Battery! We''re the manufacturer in making top-notch lithium batteries for electric cars.

Lithium-Ion Battery Manufacturing and Recycling | Pfeiffer France

Jul 22, 2025 · Reliable vacuum and leak detection solutions for lithium-ion battery production and recycling. Vacuum technology is crucial in the manufacturing, quality testing, and recycling of

Battery Production Flyer: Lithion Ion Cell Production

Feb 7, 2024 · The publication "Battery Module and Pack Assembly Process" provides a comprehensive process overview for the production of battery modules and packs. The effects

Home | Bosch Manufacturing Solutions | BMG

5 days ago · Meet Bosch Manufacturing Solutions | BMG at the Battery Show North America in Detroit, October 6-9, 2025, and discover how innovative

EV Lithium Battery PACK Design Process from

Mar 18, 2025 · EV Lithium Battery PACK Design Process: A Comprehensive Guide The design of Electric Vehicle (EV) lithium battery packs ⇱ is a complex

Battery recycling Hauts-de-France: Battri opens its first

On June 20, 2025, Battri, an innovative French start-up, opened its first battery recycling plant in Saint-Laurent-Blangy, in the Hauts-de-France region. This 161,459 sq. ft. site embodies the

LG redefines strategy: invests in battery recycling

Apr 30, 2025 · LG Energy Solution has announced the establishment of a joint venture with Derichebourg, the French leader in metal waste recycling, to

Charging a Battery Pack in France: Essential Tips for Travelers

Apr 5, 2025 · You can charge a battery pack in France with a quality power charger. Choose a lightweight, compact USB charger that works with 230-volt outlets. USB chargers are versatile

Eramet picks location for French battery recycling plant

At its research centre Eramet Ideas in Trappes, France, the miner has been developing a closed-loop optimised process to recycle batteries for electric vehicles and boost the circular economy

LG Energy Solution and Derichebourg Join Forces to

Apr 29, 2025 · In a significant move towards bolstering a sustainable battery ecosystem in Europe, LG Energy Solution (LGES) and Derichebourg, a leading French metal waste

Lithium-ion cell and battery production processes

May 3, 2018 · This Chapter describes battery cell production processes as well as battery module and battery pack assembly processes.

FEV''s eDLP

Sep 26, 2024 · eDLP – The innovative battery development and testing center Since 2008, FEV has been successfully conducting electric and thermal

Direct recycling of Li-ion batteries from cell to

Direct recycling is a novel approach to overcoming the drawbacks of conventional lithium-ion battery (LIB) recycling processes and has gained considerable

FRANCE EV BATTERY PACK MARKET SIZE & SHARE

Market Snapshot The France EV Battery Pack Market is segmented by body type (bus, light commercial vehicles (LCVs), medium and heavy-duty trucks (M&HDTs), passenger cars),

ElecSys France

ElecSys France''s high power Li-ion batteries consist of an assembly of single cells and each battery pack includes a Battery Management with Interface

CUSTOM BATTERY PACKS

Custom Battery Pack Design & Manufacture. Bespoke Battery Manufacturer with 30 Years'' Experience. ATEX, IEC, UN38.3 Certification & Testing.

Mastering the Battery Pack Assembly Process: A

Jan 23, 2025 · The battery pack assembly process is a cornerstone of modern manufacturing, essential for producing high-performance battery packs used

Lithium batteries systems to make integration in

Jun 19, 2025 · The thermal regulation of the battery has been developed with the know-how and expertise of CEA, a famous French Technology Research

LG Energy Solution Establishes Battery Recycling

Apr 29, 2025 · The new plant will specialize in pre-processing, such as discharging, dismantling and shredding battery scrap—waste generated

LGES, Derichebourg to build battery recycling

Apr 30, 2025 · Construction of the plant in the Val-d''Oise region of France will begin in 2026, with operations scheduled to start in 2027. The plant will

Battery recycling

6 days ago · A unique recycling technology Eramet Ideas, our Research & Innovation center, has developed a "closed-loop" recycling process. Unlike conventional processes, this process

Battery Manufacturing | Bosch Manufacturing Solutions | BMG

5 days ago · With over 15 years of experience in battery manufacturing, we specialize in Cell to Pack Manufacturing and Cell Technology solutions for battery modules and packs. Our

Battery Module: Manufacturing, Assembly and

Dec 28, 2022 · In the Previous article, we saw the first three parts of the Battery Pack Manufacturing process: Electrode Manufacturing, Cell Assembly, Cell

Battery Pack Manufacturing Process: Step-by-Step Guide

Dec 2, 2024 · Explore how battery cells are connected, modularized, and equipped with BMS in the Battery Pack Manufacturing Process to deliver efficient and reliable energy for multiple

LGES in battery recycling JV in France

Apr 29, 2025 · LG Energy Solution Ltd announced it has signed an agreement to establish a battery recycling joint venture with scrap metal recycler Derichebourg SA.

Neogy® | French manufacturer of energy

Neogy® is the first French battery manufacturer to obtain ECE R100 approval for batteries used in M1 and N1 category EVs (including fire and crush tests). We

BATTERY 2030+ Roadmap

Jul 11, 2022 · In the process of formulating this roadmap, the stakeholders within the entire BATTERY 2030+ initiative have been engaged, comprising academia, RTOs and industry

What Makes French Battery Companies Key Players in

Mar 1, 2025 · French battery companies are pivotal in Europe''s energy transition due to their focus on sustainable innovation, strategic partnerships, and government-backed initiatives.

Packs

The France for Battery directory introduces you to French players in the battery field nd expertise and innovation from over 100 French companies nsult their solutions & references

How are Lithium-ion Battery Packs Manufactured?

Lithium-ion battery packs are manufactured through a meticulous process that includes two key parts: the Battery Management System (BMS) and the battery pack assembly. The BMS is

LG Energy Solution, Derichebourg to Build Battery Recycling

May 5, 2025 · LG Energy Solution said it will establish a joint venture with French metal waste specialist Derichebourg to build a battery recycling plant in northern France, marking the South

BatteReverse

Aug 9, 2025 · The expertise gained in France has played a key role in TES opening South-East Asia''s first battery recycling facility in 2021 (working with a double closed loop: water process

How EV Batteries Are Made

This article explores the step-by-step process of how EV batteries are made, from raw material extraction to final assembly. It highlights the challenges faced during production and the

LG Energy Solution and Derichebourg to Launch Advanced Battery

May 2, 2025 · According to the agreement, LG Energy Solution will supply production scrap from its Polish plant, while Derichebourg will contribute used EV batteries collected across France

ACC

ACC designs and produces the cells and modules that store energy. These active elements are then assembled into battery packs by automakers to power

EasyLi

We have at our disposal a battery cell testing lab for characterization and qualification. We build validation prototypes for our customers, support the

6 FAQs about [French battery pack processing]

What is battri's first battery recycling plant in Saint-Laurent-Blangy?

On June 20, 2025, Battri, an innovative French start-up, opened its first battery recycling plant in Saint-Laurent-Blangy, in the Hauts-de-France region. This 161,459 sq. ft. site embodies the region's ambition for energy transition and a circular economy. Take a look behind the scenes of this strategic project.

How is a battery pack recycled?

First, the battery pack is removed from the packaging and discharged for safety reasons. Then, the pack is manually opened, and modules are extracted. The remaining battery pack components (casing, cables, electronics, cooling system) are sorted and recycled via TES’s network of global recycling facilities.

How many battery recycling sites does Derichebourg have?

Derichebourg operates over 200 collecting sites in France and over 285 sites worldwide. LG Energy Solution and Derichebourg plan to deepen their strategic partnership and expand their joint efforts in the battery recycling business.

What is a battery recycling facility?

The facility will specialize in the initial stages of battery recycling, including the crucial processes of discharging, dismantling, and shredding both battery manufacturing scrap and end-of-life electric vehicle (EV) batteries. At full operational capacity, the plant is projected to process over 20,000 tons of battery waste annually.

How many batteries can battri recycle a year?

Battri estimates its initial capacity at 15,000 tons per year, with the potential to expand to 35,000 tons by 2026, which means it could recycle 80,000 electric vehicle batteries. This makes it the biggest lithium-ion battery recycling plant in France.

How does Derichebourg support a closed-loop battery recycling system?

In addition, the collaboration aims to support car manufacturers seeking to establish a closed-loop battery recycling system, further promoting a circular economy. Derichebourg operates over 200 collecting sites in France and over 285 sites worldwide.

Industry Information

- Western European Low Carbon Institute Flow Battery

- Does the home inverter really work

- Photovoltaic panel power amplification

- Quad circuit breaker factory in Slovenia

- How many levels of photovoltaic panel power are there

- Photovoltaic panel household size specifications

- Base station battery reconnection

- 4 2 kw solar inverter factory in Angola

- Guyana battery energy storage module manufacturer

- Which company should I choose for double glass components

- Industrial and commercial energy storage AC combiner cabinet

- Rural solar charging panel 300 watts

- New Energy Storage Future

- Photovoltaic energy storage power supply 15 kWh

- Price of energy storage vehicle in Bosnia and Herzegovina

- Which kind of outdoor battery mobile power supply is better

- Huawei Western Europe Outdoor Power Supply Factory

- How many communication base station lead-acid batteries are there in Belize

- Wind solar and energy storage price cost

- Energy storage system on the roof

- China Solar Cycle Energy Storage Cabinet Communication Power Supply Manufacturer

- High quality solar power station portable company

- Uninterruptible Power Supply in New York USA

Commercial & Industrial Solar Storage Market Growth

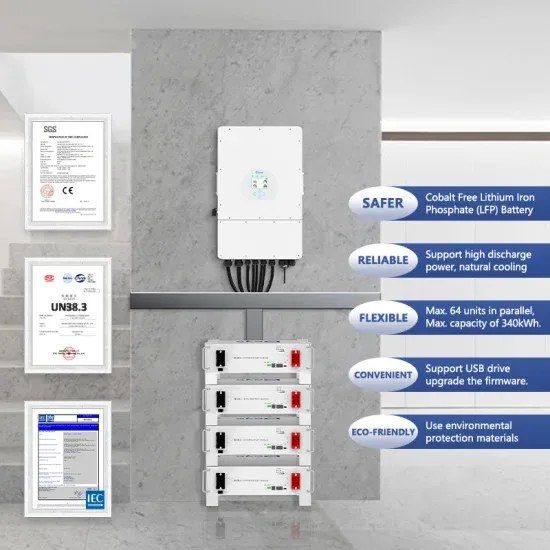

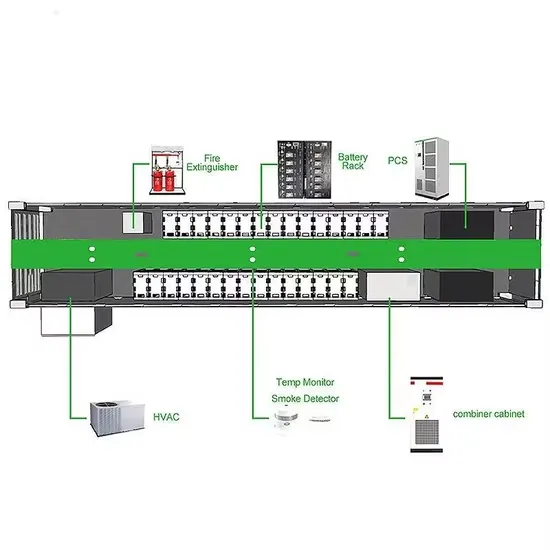

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.