Why do solar cells add sio2? | NenPower

May 18, 2024 · REDUCED SURFACE RECOMBINATION IS SIGNIFICANT FOR EFFICIENCY INCREASE. Silicon dioxide (SiO2) plays a crucial role in the realm of solar cells, greatly

What materials are commonly used in anti

Oct 17, 2024 · In conclusion, silicon nitride and titanium dioxide remain the standard materials for anti-reflective coatings on solar panels, while innovative

Hazardous Materials Used In Silicon PV Cell Production: A

The solar PV industry must address these issues immediately, or risk repeating the mistakes made by the microelectronics industry.

New anti-reflective coating for silicon solar cells

Feb 1, 2024 · Developed by an international research group, the novel anti-reflective coating is based on silicon dioxide and zirconium dioxide. It

LCA of silicon PV panels

Aug 16, 2025 · Explore the life cycle assessment (LCA) of silicon photovoltaic panels, examining their environmental impacts from production to disposal

TOPCon Solar Cells: The New PV Module

Mar 28, 2023 · Solar cell technology used to manufacture photovoltaic (PV) modules is constantly evolving as new, more advanced and more efficient

Comprehensive review on uses of silicon dioxide in solar cell

Jan 1, 2023 · Thin domestic silicon dioxide (S i O 2) inter-facial sub caste upon those photovoltaic character traits of the p-type knowing boron slender films aggregation, solar modules made of

Status and perspectives of crystalline silicon photovoltaics in

Mar 7, 2022 · Crystalline silicon solar cells are today''s main photovoltaic technology, enabling the production of electricity with minimal carbon emissions and at an unprecedented low cost. This

A review of end-of-life crystalline silicon solar photovoltaic panel

Dec 1, 2022 · With the goal of Net-Zero emissions, photovoltaic (PV) technology is rapidly developing and the global installation is increasing exponentially. Meanwhile, the world is

Solar Photovoltaic Cell Basics

1 day ago · There are a variety of different semiconductor materials used in solar photovoltaic cells. Learn more about the most commonly-used materials.

Silicon Solar Cell

Silicon solar cells are defined as photovoltaic devices made from crystalline silicon, which are characterized by their long-term stability, non-toxicity, and abundant availability. They

The Anatomy of a Solar Cell: Constructing PV

Sep 30, 2024 · Discover the remarkable science behind photovoltaic (PV) cells, the building blocks of solar energy. In this comprehensive article, we delve

How Are Solar Panels Made?

As solar energy use becomes more prevalent, so does information about how it''s harnessed and used. Photovoltaic, or solar, panels can often be found in both

Resource utilization of waste solar photovoltaic panels for

Feb 1, 2025 · With the exponential growth of global photovoltaic (PV) installed capacity, the quantity of discarded PV modules continues to rise. This study innovatively explored the

The Role of Silicon Dioxide in Solar Cells

In the context of solar cells, silicon dioxide plays a crucial role in the production of photovoltaic cells. Silicon dioxide is used as a coating on the surface of the

How is silicon for solar panels produced?

Feb 24, 2024 · How is silicon for solar panels produced? 1. The production of silicon for solar panels involves several key stages: 1. Extraction of silicon

How Do Solar Cells Work? Photovoltaic Cells

Jul 25, 2024 · In this article, we''ll look at photovoltaic (PV) solar cells, or solar cells, which are electronic devices that generate electricity when exposed to

Are Solar Panels Made of Silicon or Silicon Dioxide?

Nov 23, 2023 · Solar panels are primarily made of silicon, not silicon dioxide. Silicon is a semiconductor material that is a key component in the manufacturing of photovoltaic (PV)

Status and perspectives of crystalline silicon photovoltaics in

Mar 7, 2022 · Crystalline silicon solar cells are today''s main photovoltaic technology, enabling the production of electricity with minimal carbon emissions and at an unprecedented low cost.

The Environmental Impact of Photovoltaics

Explore the comprehensive environmental impact of photovoltaic (PV) technology, from raw material extraction and manufacturing to end-of-life

Comprehensive review on uses of silicon dioxide in solar cell

Sep 1, 2022 · Silicon Dioxide is a pleasant material with a wide range of application in semiconductor devices. Ago days silicon solar panels utilized to exist readily precious as

SiO2 surface passivation layers – a key technology for silicon solar

Oct 1, 2018 · It allowed to develop the first 20% efficient silicon solar cells in the past and currently experiences a renaissance as the interfacial oxide for silicon-based passivating contacts, thus

Silicon-based photovoltaic solar cells

Jan 1, 2012 · The dominant contributor to PV energy generation capacity, at present and for the foreseeable future, is silicon-based technology; in particular, crystalline (c-Si) and

Comprehensive study on photovoltaic cell''s generation and

Feb 19, 2025 · Amorphous solar panels are created through the deposition of non-crystalline silicon onto a substrate made of glass, plastic, or metal, as opposed to the utilisation of solid

Life Cycle Greenhouse Gas Emissions of

Mar 19, 2012 · A module is a panel of electrically connected solar PV cells, and in addition to the cells, includes the frame and glass. A PV array consists of

How Are Solar Panels Made?

Oct 19, 2022 · Before it''s used in a solar panel, silicon dioxide must be turned into pure "metallurgical grade silicon " (MGS). This process uses a lot of energy:

Life Cycle Greenhouse Gas Emissions from Solar

Jul 11, 2023 · Life Cycle Greenhouse Gas Emissions from Solar Photovoltaics Over the last thirty years, hundreds of life cycle assessments (LCAs) have been conducted and published for a

New anti-reflective coating for silicon solar cells

Feb 1, 2024 · An international group of scientists investigated the use of silicon dioxide (SiO2) and zirconium dioxide (ZrO2) as an anti-reflection coating for

Silicon for Solar Cells: Everything You Need to

Are these the reasons why silicon is synonymous with semiconductors and solar cells? Why is silicon used in solar panels? Let''s explore further and find out.

Silicon Solar Cells

1 day ago · The cells are distinguished from polycrystalline silicon cells by their form. Monocrystalline solar cells also have a consistent black colour

Japan Unveils Titanium Solar Panels That Are 1,000 Times

Feb 24, 2025 · Traditional solar panels rely on silicon, but the new titanium-selenium panels have demonstrated higher efficiency due to an advanced manufacturing process. Scientists

Carbon Footprint of Solar Panel Manufacturing

May 14, 2024 · Carbon Footprint of Solar Panel Manufacturing: About 0.66kg silicon is used to manufacture a PV panel realising about 6.0kg of CO2e per kilo.

How Are Solar Panels Made?

Oct 19, 2022 · Silicon, in the form of silicon dioxide sand and gravel, is the second most abundant element on Earth, next to oxygen. Before it''s used in a solar

6 FAQs about [Solar Photovoltaic Panel Silicon Dioxide]

Can SiO2 be used in photovoltaic?

Application of SiO2 in photovoltaic The surface modification of the silicon solar cells surface was unable to achieve an efficiency of more than 20 %. Surface passivation in thermally produced SiO 2 is one of the earliest option . In the history of silicon solar cells, when oxides were adapted.

Is silicon dioxide a good material for solar panels?

Silicon Dioxide is a pleasant material with a wide range of application in semiconductor devices. Ago days silicon solar panels utilized to exist readily precious as veritably high-quality, silicon was needed for creating them. The evolution of technology directly permitted the application of inexpensive and lesser quality silicon.

Which element is used in a solar panel?

Silicon, in the form of silicon dioxide sand and gravel, is the second most abundant element on Earth, next to oxygen. Before it’s used in a solar panel, silicon dioxide must be turned into pure “metallurgical grade silicon ” (MGS).

What is silicon dioxide (SiO2) used for?

The usage of silicon dioxide (SiO 2) to improve the surface modification properties of silicon solar cells is common. A silicon oxide coating is commonly employed as an insulator to reduce solar cell potential-induced deterioration when the PV module is installed outside.

What are crystalline silicon solar cells?

Crystalline silicon solar cells are today’s main photovoltaic technology, enabling the production of electricity with minimal carbon emissions and at an unprecedented low cost. This Review discusses the recent evolution of this technology, the present status of research and industrial development, and the near-future perspectives.

Which material is used in a solar cell?

A very well thin film technique is amorphous silicon, while microcrystalline silicon is used in an a-Si solar cell. CdTe are the second most common PV materials after silicon, and it can be produced using a low-cost production process. Its efficiency ranges from 15 to 16 %.

Industry Information

- Basic principles of communication green base station link

- Costa Rica solar lights illuminate all four sides

- 2gw high-efficiency photovoltaic module R

- Indonesia Wind and Solar Energy Storage Planning

- What are the battery cabinets in Yaounde

- France Lyon Mobile Energy Storage Vehicle Wholesale

- Miniaturized 5G base station power supply

- Tunisia-specific energy storage battery

- Riyadh Solar Photovoltaic Panels

- China China circuit breaker outside company

- Cape Town Generator Container BESS

- High quality high quality 220 gfci breaker Seller

- Lusaka Photovoltaic Energy Storage System

- Solar power generation system in rural Lyon France

- Algiers Communication Base Station Wind Power Outdoor Site

- Cairo high frequency uninterruptible power supply price

- Lithium Energy Storage Power Price in Mozambique

- Zambia Telecom PV Site

- Huawei Maldives photovoltaic glass brand

- Slovenia outdoor power bms company

- How to supply power to the base station

- Difference between 12v and 24v outdoor power batteries

- British Zhaofu Photovoltaic DC Combiner Box

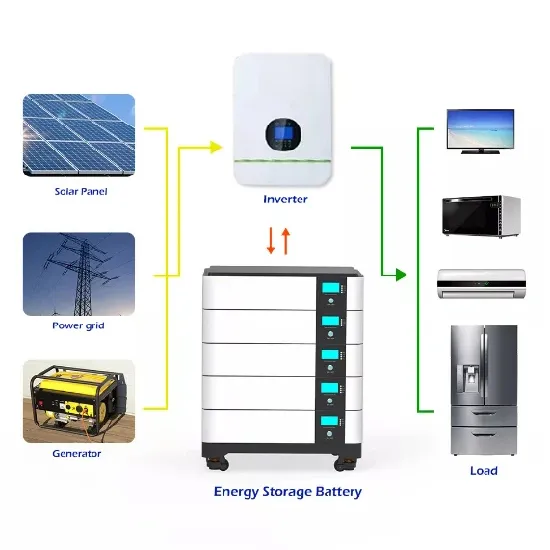

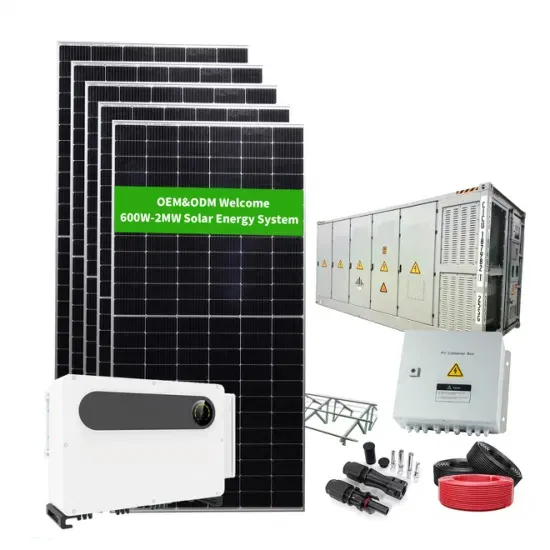

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.