Battery Cells, Modules, and Packs | Lithium-ion

Curious about Battery cells, modules, and packs? These are the fundamental building blocks of modern energy storage systems, driving everything from

What Is A Lithium-Ion Battery Cell, Module, and

Jan 30, 2024 · We will delve into the components that make up a lithium-ion battery system, exploring the differences of battery cells, battery modules, and

Battery structure

3 days ago · Lead-acid battery is a traditional battery technology, which is composed of positive plate group, negative plate group, separator, container

Lithium-ion Battery – How it works – Electricity –

Feb 23, 2025 · Lithium-ion Battery A lithium-ion battery, also known as the Li-ion battery, is a type of secondary (rechargeable) battery composed of cells in

Battery Cell VS Battery Module VS Battery Pack

Battery Module: A group of interconnected battery cells that increases voltage and capacity compared to individual cells. It includes wiring and connectors

Guide to Battery Anode, Cathode, Positive,

Mar 26, 2024 · During the discharging of the lithium battery, lithium ions are released from the anode side and flow towards the cathode. So, it is the

Science 101: Batteries

4 days ago · What is a battery? Batteries power our lives by transforming energy from one type to another. Whether a traditional disposable battery (e.g., AA)

Lithium-ion battery PACK knowledge comprehensive

The main hardware components of two-wheeler lithium battery PACK include: fire-proof shell, LED display (just used in parts of battery packs), smart BMS, cells, cell holder, sealing ring, cell

Battery Cell, Module, Pack, what`s the Difference?

Nov 20, 2024 · Cylindrical battery cells were the first lithium-ion batteries to achieve mass production. They''re made by winding the cathode, anode, and separator in a specific order

From Cells to Cases: The Anatomy of a Battery

Aug 27, 2024 · In the realm of modern technology, battery packs serve as the beating heart of many devices, from electric vehicles to portable electronics.

Inside a Lithium Battery: Components and

May 13, 2025 · To understand what''s inside a lithium ion battery, we need to explore its internal structure, from the cathode to the separator. A lithium-ion

BU-302: Series and Parallel Battery Configurations

BU-302: Configuraciones de Baterías en Serie y Paralelo (Español) Batteries achieve the desired operating voltage by connecting several cells in series;

Understanding Lithium-ion

It was not until the early 1970s that the first non-rechargeable lithium batteries became commercially available. Attempts to develop rechargeable lithium

Lithium Battery Configurations – Topak energy

When you take off the top of a lithium battery pack, you''ll first notice the individual cells and a circuit board of some kind. There are three types of cells that are used in lithium batteries:

Design approaches for Li-ion battery packs: A review

Dec 20, 2023 · The paper analyzes the design practices for Li-ion battery packs employed in applications such as battery vehicles and similar energy storage systems. Twenty years ago,

How to Explore the Anatomy of Lithium Ion Batteries

Feb 21, 2025 · Exploring the anatomy of lithium-ion batteries reveals essential components that contribute to their functionality, efficiency, and safety in various applications, from smartphones

Lithium Battery Chemistry: How is the voltage

Mar 23, 2023 · Voltage window of batteries First of all, it should be clarified why a voltage between the positive and negative pole can be measured. The voltage

What Does "Group" Mean in Batteries?

What Does "Group" Mean in Batteries? When selecting a battery, you may come across the term "Group," such as "Group 27″ or "Group 31." But what does "Group" mean in batteries? How

What is the packaging technology of soft pack Li

Jun 11, 2022 · Soft pack lithium-ion batteries are always found in consumer electronics, as UAV/drone batteries, and the high-performance batteries of

The principle of the lithium-ion battery (LiB)

The principle of the lithium-ion battery (LiB) showing the intercalation of lithium-ions (yellow spheres) into the anode and cathode matrices upon charge and

How Do Lithium Ion Batteries Work?

Nearly all lithium batteries are Consists of 3 main parts—— Cells, BMS, Housing. The Bracket only plays the role of fixing the battery. So I will not focus on

Numerical assessment of the side impacts on lithium-ion battery

Jul 1, 2024 · In the present study, finite element numerical modelling was performed to estimate the damage to a lithium-ion battery (LIB) pack attached to a Toyota Camry car model in the

Series and Parallel, which is the first when assembling lithium battery

Aug 27, 2024 · Series and Parallel, which is the first when assembling lithium battery packs? In the design of the battery modules, whether to connect them in series first and then in parallel

Understanding Lithium-Ion Battery Packs: A Beginner''s Guide

Aug 9, 2024 · A lithium-ion battery pack is a collection of individual lithium-ion cells grouped together to increase voltage and capacity. These packs are designed to store and deliver

LITHIUM BATTERIES 101

Apr 28, 2022 · Lithium 101 Introduction A brief history and overview of advanced battery chemistry: The first lithium-ion battery prototype Popular lithium (ion) cell types: What are

A review of lithium-ion battery safety concerns: The issues,

Aug 1, 2021 · Lithium-ion batteries (LIBs) with excellent performance are widely used in portable electronics and electric vehicles (EVs), but frequent fires and explosions limit their further and

Breaking Down Lithium-Ion Battery Diagrams for Beginners

May 30, 2025 · Understand lithium-ion battery diagrams with ease. Learn key components, symbols, and steps to read diagrams for troubleshooting or designing battery systems.

Factors Influencing the Design of Custom

Apr 30, 2024 · As experts in custom battery pack design, we understand the intricate details that go into creating high-performance and reliable power

The Construction of the Li-ion Battery Pack

Jul 29, 2020 · Learn about the various components that are needed to build a functional & safe battery pack in this week''s Li-ion Battery 101 blog.

18650 Battery Which Side Is Positive-battery-knowledge

Aug 18, 2020 · Do you still get confused regarding which side of the battery is positive, and which is negative? If your answer is yes, then don''t be embarrassed. Hundreds and thousands of

Battery 101: The Fundamentals of How a Lithium

Feb 8, 2024 · How does a lithium-ion battery work? It''s a question many battery users have asked themselves when eyeing these high-quality lithium batteries

A deep analysis of lithium battery in series and

2 days ago · In the development of modern technology, lithium batteries have become the primary power source for various electronic devices and electric

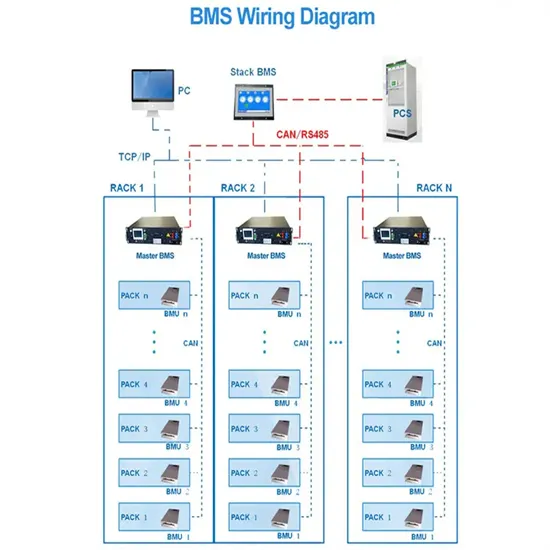

Analysis of common failures of BMS, an

Jul 28, 2025 · BMS is an important accessory of Li-ion battery pack, it has a lot of functions, Li-ion battery management system BMS as a strong guarantee of

6 FAQs about [Which side of the lithium battery pack is the first group]

What are the different types of lithium ion battery cells?

Lithium-ion battery cells come in three main formats: cylindrical, prismatic, and pouch cells. Cylindrical battery cells were the first lithium-ion batteries to achieve mass production. They’re made by winding the cathode, anode, and separator in a specific order into a cylinder shape and then housing it in a metal casing.

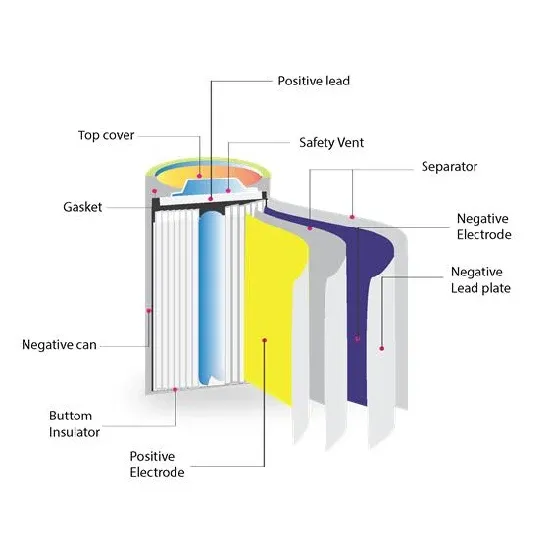

What is the structure of lithium battery?

Lithium battery structure consists of positive electrode, negative electrode, separator, electrolyte, etc. The positive electrode is usually made of lithium metal oxide, while the negative electrode is made of graphite. The electrolyte is usually a lithium salt dissolved in an organic solvent.

How do lithium ions move in a battery?

When the battery is charged, lithium ions are generated on the positive electrode of the battery, and the generated lithium ions move to the negative electrode through the electrolyte. As an anode, the carbon is layered. It has many micropores. Lithium ions that reach the negative electrode are embedded in the micropores of the carbon layer.

How to use lithium-ion batteries correctly?

How to use lithium-ion batteries correctly? Avoid excessive discharge. When the device prompts "low battery", it should be charged; Don't charge until the device shuts down automatically. The battery has been discharging excessively. This can affect battery life. Avoid overcharging. The charger should be unplugged when it is indicated to be full.

What are lithium ion batteries?

Figure. 1 Lithium-ion batteries are rechargeable batteries that mainly rely on lithium ions moving between the positive and negative electrodes to work.

What is a lithium battery made of?

The container is made of hard rubber or plastic and contains an electrolyte, usually sulfuric acid. Lithium battery structure consists of positive electrode, negative electrode, separator, electrolyte, etc. The positive electrode is usually made of lithium metal oxide, while the negative electrode is made of graphite.

Industry Information

- Small UPS uninterruptible power supply custom price

- Dushanbe backup energy storage battery

- How much is the subsidy for photovoltaic energy storage

- Iran Uninterruptible Power Supply Equipment

- Energy storage charging pile equipment manufacturer

- American battery storage box

- Can a 60v inverter be plugged into a 50v battery

- Majuro Mobile Outdoor Power Supply

- Photovoltaic energy storage cabinet Solar photovoltaic

- Photovoltaic panels directly connected to industrial frequency inverter

- What does the interior of the lithium iron phosphate battery station cabinet look like

- Estonia Energy Storage Project

- Base station range of container

- 5Kw inverter price for solar power generation

- Install a solar system at home

- Industrial breaker manufacturer

- RV GEL Battery Solar System

- China battery circuit breaker in Brisbane

- Energy storage system data is sent to the dispatcher

- Large-area photovoltaic panel size

- Neutral Red Flow Battery

- Prices of polycrystalline photovoltaic panels in Sydney Australia

- High quality 5kw solar system in Nicaragua

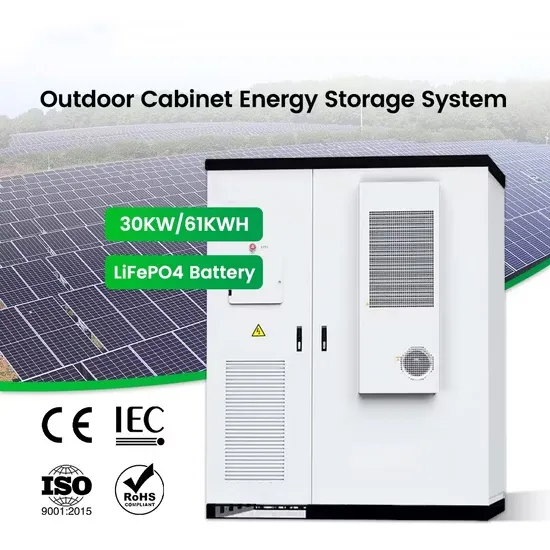

Commercial & Industrial Solar Storage Market Growth

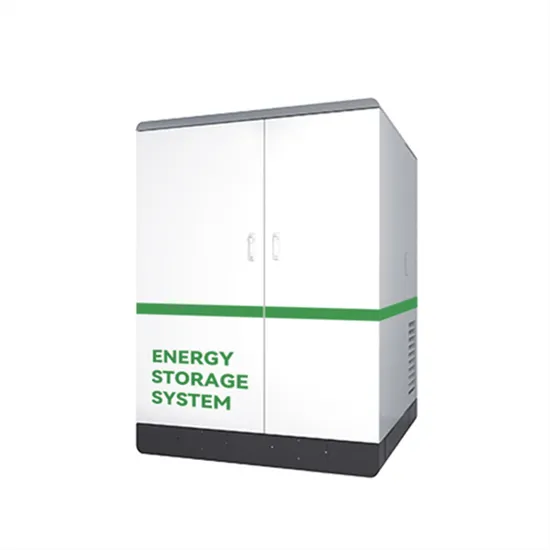

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.