Inventions, innovations, and new technologies: Flexible and

Sep 1, 2023 · We review recent inventions and innovations to enhance the distinctive properties and functionalities of thin-film devices for successfully adapting in the emerging applications.

Thin-Film Solar Panels

Feb 27, 2021 · B. How Thin-Film Solar Cells are Made? Thin-Film solar cells are by far the easiest and fastest solar panel type to manufacture. Each thin-film solar panel is made of 3 main parts:

CIGS thin-film solar module processing: case of high-speed

Jan 13, 2017 · In this paper, we investigate the laser processing of the CIGS thin-film solar cells in the case of the high-speed regime. The modern ultra-short pulsed laser was used exhibiting

Front glass crack inspection of thin-film solar photovoltaic modules

May 1, 2024 · Ensuring the structural integrity of solar photovoltaic modules is crucial to maintain power production efficiency and fulfill the anticipated product lifespan. Hence, implementing

A comparative study of different materials used for solar

Jan 1, 2022 · The paper presents a holistic review of three primary solar photovoltaic technologies, the dominant crystalline silicon photovoltaic, thin-film photovoltaic, and much

Thin Film Photovoltaics

Thin film photovoltaic modules produce power at low cost per watt. They are ideal for large scale solar farms, as well as Building Integrated Photovoltaic applications (BIPV). They benefit from

Emerging Thin Film Solar Panels

Jan 8, 2020 · 1.2 Photovoltaic technologies The present PV technologies could be classified in two categories: (1) wafer-based (2) thin film cells (Figure 1). Wafer-based cells are fabricate on

Thin Film Photovoltaics

Jan 1, 2018 · Thin film technology has the answers and potential to eliminate many existing bottlenecks of c-Si photovoltaic (PV) programs experienced at different levels from module

A novel approach for the recycling of thin film photovoltaic modules

Aug 1, 2010 · A sustainable recycling of photovoltaic (PV) thin film modules gains in importance due to the considerable growing of the PV market and the increasing scarcity of the resources

Advances in nanostructured thin film materials for solar cell

Jun 1, 2016 · This paper reviews recent advances in photovoltaic devices based on nanostructured materials and film designs, focusing on cadmium telluride (CdTe), copper zinc

PVthin | Thin-Film PV Technology

Sep 11, 2023 · Thin-film technologies have the smallest environmental footprint of all photovoltaic conversion technologies. Due to their energy and material

Mitsubishi Thin Film Photovoltaic Module

May 13, 2021 · The thin-film (a-Si) PV module is a nections of modules, the effect of voltage drop due to technology highly expected as a module for low manufactur- shadow (shade) can be

What are thin-film solar cells? description, and types

Sep 26, 2019 · Silicon modules are divided into three categories: Amorphous silicon photovoltaic cells Multicrystalline tandem photovoltaic cells Multicrystalline silicon thin film on glass The

A Comprehensive Review on Current

Nov 19, 2022 · Due to the recent surge in silicon demand for solar modules, thin-film photovoltaic (PV) modules have a potential to penetrate the market in

Characterization Thin Film Modules

The first portion of the report deals with the performance of thin-film PV modules in solar simulators. Achieving repeatable performance measurements is challenging, even under

Thin-film modules: Benefits and considerations

May 8, 2023 · What are thin-film solar photovoltaic (PV) modules and what are the main considerations when using them in a utility-scale solar plant?

Thin-film modules: Benefits and considerations

May 8, 2023 · Thin-film photovoltaic (PV) modules are among the main alternatives to silicon modules in commercial solar energy systems. Thin-film

Thin-Film Solar Technology (2025) | 8MSolar

Dec 30, 2024 · Thin-film solar technology represents a departure from traditional silicon-based solar panels. Instead of using thick layers of crystalline silicon,

What is Thin Film Photovoltaic Module?

Nov 17, 2023 · What is Thin Film Photovoltaic Module consist of layers containing amorphous silicon, cadmium telluride, or copper indium gallium selenide.

MIT scientists produce new organic photovoltaic

Dec 9, 2022 · MIT scientists produce new organic photovoltaic fabrics US researchers have developed a thin-film organic solar module on a vapor

Towards sustainability via recycling solar photovoltaic

Jan 1, 2025 · For instance, although the same chemical etching procedures can be used, the recovery chemistry for CIS thin-film modules differs from CdTe modules and needs more

Recent Advancements in Thin-Film Solar Modules

Jun 9, 2025 · Thin-film solar modules transform the renewable energy landscape with their lightweight design, flexibility, and cost-effective production. Unlike

CIGS Thin Film Photovoltaic—Approaches and

Nov 28, 2019 · After a short overview of the historical development of the Cu (In, Ga)Se 2 (CIGS) thin film solar cell and its special features, we give an

First Solar issues 2024 Sustainability Report

Sep 9, 2024 · According to its 2024 Sustainability Report, cadmium telluride (CdTe) thin-film photovoltaic (PV) module maker First Solar Inc of Tempe, AZ, USA has established new

Thin-Film Solar Photovoltaics: Trends and Future Directions

Aug 7, 2025 · Abstract and Figures Thin-film photovoltaic (PV) technologies address crucial challenges in solar energy applications, including scalability, cost-effectiveness, and

Characterization of Performance of Thin-film PV

Apr 15, 2020 · Although thin-film photovoltaic (PV) modules have been in production for decades, the characterization of their performance, both outdoors and under artificial light, remains a

Thin Films Photovoltaics

Feb 23, 2022 · Thin film photovoltaic-based solar modules produce power at a low cost per watt. They are ideal candidates for large-scale solar farms as well

Thin-film solar panels: What you need to know

Feb 13, 2023 · What are thin-film solar panels? Thin-film modules use one of the following four technologies: cadmium telluride (CdTe), amorphous silicon (a

Thin Film Photovoltaic Modules with Structural Bonds

Apr 5, 2012 · FIG. 5 is a schematic representation of a portion 500 of a photovoltaic module illustrating an extension 504 of structural bonding material 502 positioned between

A comprehensive evaluation of solar cell technologies,

Jun 1, 2024 · Thin-film solar cells offer flexibility and versatility in design, making them suitable for curved surfaces, building-integrated photovoltaic (BIPV) applications, and portable devices.

Thin Film Photovoltaics

Oct 7, 2013 · The Idea of Low-Cost PV The motivation to develop thin film technologies dates back to the inception of photovoltaics. It is an idea based on achieving truly low-cost

A review of primary technologies of thin-film

Sep 23, 2021 · Thin-film solar cells are preferable for their cost-effective nature, least use of material, and an optimistic trend in the rise of efficiency. This

CdTe photovoltaic technology: An overview of waste

Jun 1, 2024 · CdTe panel is a leader among thin-film technologies for solar panels and, according to some studies, promises the lowest production cost compared with other PV technology

6 FAQs about [Platinum thin film photovoltaic modules]

What are thin-film photovoltaic (PV) modules?

Thin-film photovoltaic (PV) modules are among the main alternatives to silicon modules in commercial solar energy systems. Thin-film technologies account for a small but growing share of the global solar market and are expected to grow at a compound annual growth rate of 23% from 2020-2025.

What is thin-film solar technology?

Thin-film solar technology represents a departure from traditional silicon-based solar panels. Instead of using thick layers of crystalline silicon, thin-film solar cells are made by depositing one or more thin layers of photovoltaic material onto a substrate.

Where are thin-film solar panels used?

Thin-film technology is mostly used in the US, where the largest remaining solar panel producer, First Solar, produces CdTe modules. The US government has imposed tariffs on imports of silicon solar cells from China, aiming to provide support for domestic manufacturing.

What are the different types of thin-film solar panels?

Before comparing the different types of thin-film solar panels against crystalline silicon solar panels (c-Si), it is important to remark that there are two main types, monocrystalline silicon (mono c-Si) and polycrystalline silicon (poly c-Si) solar panels.

When did thin-film solar panels come out?

In 1980, researchers finally achieved a 10% efficiency, and by 1986 ARCO Solar released the G-4000, the first commercial thin-film solar panel. Thin-film solar panels require less semiconductor material in the manufacturing process than regular crystalline silicon modules, however, they operate fairly similar under the photovoltaic effect.

Are thin-film solar panels a good choice?

Flexibility: Unlike rigid silicon panels, many thin-film solar cells can be made flexible. This allows for integration into curved surfaces, portable devices, and even clothing. Lightweight: The thinness of these solar cells makes them much lighter than traditional panels.

Industry Information

- What are the wind and solar complementary maintenance equipment for communication base stations

- Milan Italy 20 photovoltaic energy storage

- Outdoor base station typhoon resistance

- Is lithium metal battery an energy storage cabinet battery

- Esb energy storage power supply

- China upgrade circuit breaker in Turkey

- North Asia outdoor communication battery cabinet customization

- Ups pure sine wave industrial frequency inverter

- 4680 battery to 12v24v outdoor power supply

- Solar thin-film battery costs more than one watt

- Dominican Communication Base Station Hybrid Energy Tower

- How much can a portable outdoor power bank charge

- Photovoltaic panel manufacturers wholesale cost price

- Niger computer room UPS uninterruptible power supply manufacturer

- China dual circuit breaker in China Seller

- Relationship between energy storage devices and power grid

- Energy storage product finalization

- Lesotho containerless solar case

- Blown circuit breaker factory in Yemen

- Dominic outdoor communication battery cabinet performance test system

- Banji factory photovoltaic solar panels

- Main breaker switch in China in Afghanistan

- Residual value of energy storage power station

Commercial & Industrial Solar Storage Market Growth

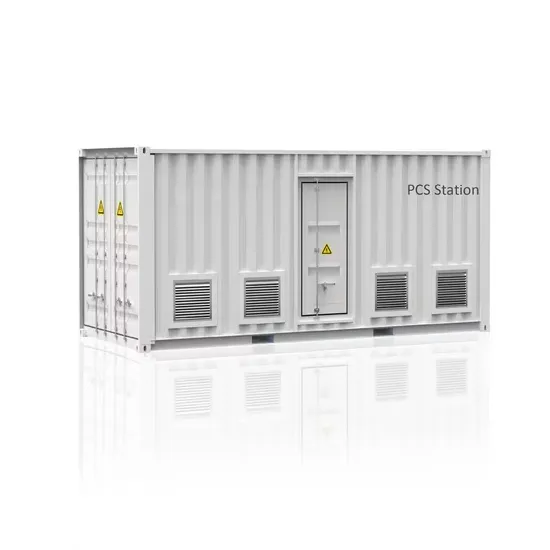

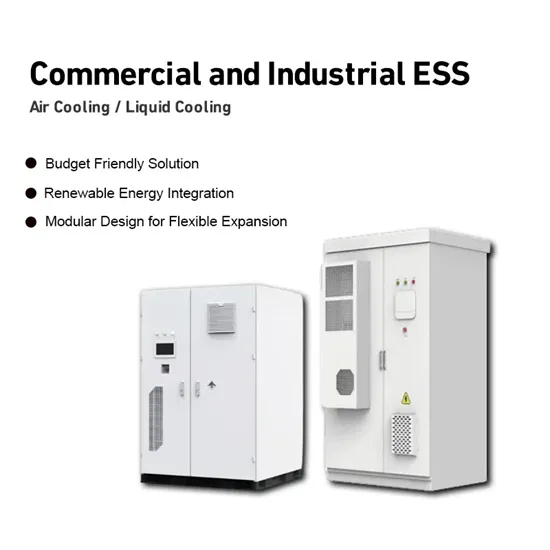

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.