Research on recycling of metal Si and Ag from waste photovoltaic

The lifetime of photovoltaic modules is generally 20–30 years, so the first batch of photovoltaic modules will be retired extensively in the coming years [8]. The first batch of photovoltaic

Photovoltaic recycling: enhancing silicon wafer recovery

Apr 30, 2024 · Through investigation, this research demonstrates the feasibility and cost-effectiveness of silicon wafer recovery from damaged silicon solar panels. As photovoltaic

The solar cell wafering process

May 21, 2024 · A Weibull graph shows the failure probability versus bending stress applied during the 4-line bending test of two sets of monocrystalline silicon wafers. the black triangles

Review of c-Si PV module recycling and

Jan 21, 2025 · Solar cells are the basic components of photovoltaic modules and account for about 4 per cent of their total weight. Commercial photovoltaic

Window-Integrated PV Glass: The Future of Solar

Feb 19, 2025 · Photovoltaic (PV) glass stands at the forefront of sustainable building technology, revolutionizing how we harness solar energy in modern

Flexible solar cells based on foldable silicon wafers with

May 24, 2023 · In this study, we propose a morphology engineering method to fabricate foldable crystalline silicon (c-Si) wafers for large-scale commercial production of solar cells with

A promising method for the liberation and separation of

Oct 15, 2023 · Recycling waste PV modules has economic value because of their valuable components, such as tempered glass, silicon wafers, aluminum frames, copper, silver, etc. It is

Review of silicon recovery in the photovoltaic industry

Dec 1, 2023 · The photovoltaic industry is developing rapidly to support the net-zero energy transition. Among various photovoltaic technologies, silicon-based technology is the most

Material Recovery from End-of-Life Solar Photovoltaic

May 6, 2023 · The expected life of photovoltaic (PV) modules is 10–20 years as solar modules degrades over the course of time. This degradation is mainly due to the water ingress, ultra

Status and perspectives of crystalline silicon photovoltaics in

Mar 7, 2022 · Crystalline silicon solar cells are today''s main photovoltaic technology, enabling the production of electricity with minimal carbon emissions and at an unprecedented low cost. This

A method to recycle silicon wafer from end-of-life photovoltaic

Apr 1, 2017 · A method to recycle silicon wafer from end-of-life photovoltaic module and solar panels by using recycled silicon wafers

Thermo-mechanical stress modelling and fracture

Mar 1, 2025 · Thinning of crystalline silicon (c-Si) wafers will reduce material cost and improve productivity, which significantly impacts the development of solar photovoltaic (PV) industry.

Eco-friendly method for reclaimed silicon wafer from

A sustainable method for reclaiming silicon (Si) wafer from an end-of-life photovoltaic module is examined in this paper. A thermal process was employed to remove ethylene vinyl acetate

Research on new process for separation of silicon wafers

Research on new process for separation of silicon wafers and glass from decommissioned photovoltaic modules Jian wen Zhang 1,2, Hai dong Wang 1, Sheng guang Zhang 2, Han

Silicon Recycling and Recovery in Photovoltaic Industry

Jun 11, 2025 · The increasing global expansion of the photovoltaic (PV) industry has brought to the forefront the critical need for sustainable management of silicon waste. Silicon recycling

Advancements in end-of-life crystalline silicon photovoltaic

Oct 15, 2024 · The remaining glass, front EVA, and silicon wafers were maintained at 650 °C for 30 min, and EVA was decomposed to obtain glass and silicon wafers. This method not only

Short process recovery of silver and purification mechanism

Apr 15, 2025 · Kanellos et al. [16] heated the photovoltaic cells at 550 °C for 15 min to separate the glass from the silicon wafers. Wang et al. [17] investigated the pyrolysis behavior of

Research on new process for separation of silicon wafers and

4 days ago · Analysis characteristics of photovoltaic arrays using simulation Fast Method to Determine the Structural Defect Density of 156 x 156 mm2 Mc-Si Wafers Minimum Silicon

Research on new process for separation of silicon wafers

This study provides a research idea for the industrial separation of silicon wafers and glass from decommissioned photovoltaic modules. Keywords: crystalline silicon photovoltaic modules,

Kinematic mechanics study of silicon wafers and glass

Sep 15, 2024 · In this paper, the static friction coefficient of different particle sizes silicon wafers, glass particles and separation platform are measured by the

Solar Photovoltaic Manufacturing Basics

4 days ago · Cell Fabrication – Silicon wafers are then fabricated into photovoltaic cells. The first step is chemical texturing of the wafer surface, which removes

The solar cell wafering process

May 21, 2024 · In this paper, the basic principles and challenges of the wafering process are discussed. The multi-wire sawing technique used to manufacture wafers for crystalline silicon

The research progress on recycling and resource utilization

Jun 15, 2024 · Komoto et al. [32] asserted that the recycling objectives for crystalline silicon photovoltaic modules involve the separation and recovery of glass, silicon cells, and other metals.

A review of end-of-life crystalline silicon solar photovoltaic

Dec 1, 2022 · Upcycling aims to recover high-grade glass, silicon wafers and valuable metals including Ag, Cu and Al from EOL c-Si PV panels. After mechanical or manual removal of Al

Wafering – PV-Manufacturing

6 days ago · Figure 1: Photograph of four bricks in a wire-saw machine ready to be sliced (picture courtesy of Trina Solar). Wafers are produced from slicing a

A critical review on the fracture of ultra-thin photovoltaics silicon

Aug 15, 2024 · Silicon-based solar photovoltaics cells are an important way to utilize solar energy. Diamond wire slicing technology is the main method for producing solar photovoltaics cell

Wafer-Based Solar Cell

Wafer-based solar cells refer to solar cells manufactured using crystalline silicon (c-Si) or GaAs wafers, which dominate the commercial solar cell industry and account for a significant portion

A novel acid-free combined technology to achieve the full

Dec 15, 2024 · Currently, strong acid reagents are commonly used in the recovery of silver from crystalline silicon photovoltaic waste, posing environmental risks and restricting the

Non-destructive recovery of silicon wafers from waste photovoltaic

Request PDF | On Jan 1, 2025, Weiyao Li and others published Non-destructive recovery of silicon wafers from waste photovoltaic modules and investigation of their etching behavior |

Solar PV Manufacturing Basics Explained

2 days ago · Learn solar photovoltaic manufacturing basics, PV modules, racking systems, power electronics, and costs in a simple guide.

Effectively and completely separating the waste crystalline silicon

Jun 22, 2025 · This study proposes a novel strategy for separating silicon-based PV modules using green solvents, including the following steps: mechanical cutting, mechanical treatment

Non-destructive recovery of silicon wafers from waste photovoltaic

Jul 19, 2025 · Waste PV modules contain a significant amount of valuable resources, including aluminum, silver, and silicon. Research statistics predict that by 2050, waste PV modules will

A Review of End‐of‐Life Silicon Solar

Dec 12, 2024 · The objective, however, remains the same; layer separation and encapsulant removal allowing for the recovery of high-grade solar glass,

What Is a Silicon Wafer for Solar Cells?

Aug 27, 2024 · Silicon Valley got the name for a reason — and less refined forms of silicon are also used to manufacture concrete, glass, and silicone rubber.

Photovoltaics Manufacturing, Polysilicon | Solar Power

PV manufacturing includes three distinct processes: 1. Manufacturing silicon (polysilicon or solar-grade), 2. wafers (mono- or polycrystalline) and 3. cells and modules (crystalline and thin-film).

6 FAQs about [Photovoltaic glass and silicon wafers]

What are silicon wafer-based photovoltaic cells?

Silicon wafer-based photovoltaic cells are the essential building blocks of modern solar technology. EcoFlow’s rigid, flexible, and portable solar panels use the highest quality monocrystalline silicon solar cells, offering industry-leading efficiency for residential on-grid and off-grid applications.

Do thin-film solar cells use silicon wafers?

Thin-film solar cells don’t use silicon wafers but are highly inefficient and rarely used. Silicon wafer-based photovoltaic cells are the essential building blocks of modern solar technology.

Which solar panels use wafer based solar cells?

Both polycrystalline and monocrystalline solar panels use wafer-based silicon solar cells. The only alternatives to wafer-based solar cells that are commercially available are low-efficiency thin-film cells. Silicon wafer-based solar cells produce far more electricity from available sunlight than thin-film solar cells.

How to reclaim silicon (Si) wafer from end-of-life photovoltaic module?

A sustainable method for reclaiming silicon (Si) wafer from an end-of-life photovoltaic module is examined in this paper. A thermal process was employed to remove ethylene vinyl acetate and the back-sheet. We found that a ramp-up rate of 15 °C/min and an annealing temperature of 480 °C enabled recovery of the undamaged wafer from the module.

Are silicon wafers a good choice for high-efficiency solar cells?

In recent years, the diameter of silicon wafers manufacturers use for high-efficiency solar cells has increased — and so has the performance. Wafers as large as 210mm 2 (M12) are increasingly used in PV cells — a 35% increase in diameter from the original M0.

How are silicon wafers made?

Cell Fabrication – Silicon wafers are then fabricated into photovoltaic cells. The first step is chemical texturing of the wafer surface, which removes saw damage and increases how much light gets into the wafer when it is exposed to sunlight. The subsequent processes vary significantly depending on device architecture.

Industry Information

- Which kind of UPS is good in Asia

- Solar lights for home outdoor floodlights

- Portable battery cabinet processing

- 24v home inverter 220v price

- Freetown Industrial Energy Storage Cabinet Customization Company

- What are the complementary effects of wind and solar power in communication base stations

- Photovoltaic transparent solar glass

- St Johns Power Energy Storage Battery Merchant

- 12v sine wave inverter kit

- Solar energy supplier for communication base stations

- Battery PACK Busbar

- 9a lithium battery pack

- San Diego Energy Storage Explosion-Proof Container

- Home wall-mounted energy storage photovoltaic power generation

- Power supply inside the base station

- 218V inverter voltage

- How many base stations are there in Guinea s 5G communications operation

- Uninterruptible power supply sales price in Zambia

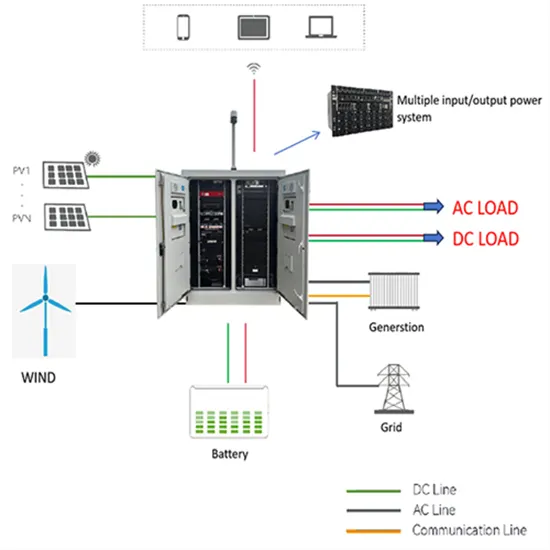

- Grid-connected and off-grid photovoltaic power generation systems

- UPS battery cabinet configuration

- Large Mobile Energy Storage Station BESS

- High quality factory price d curve breaker producer

- Which 5G base station companies are there in Dubai

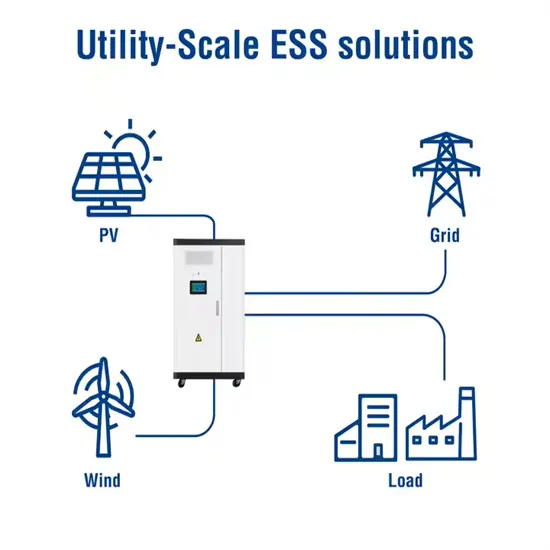

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

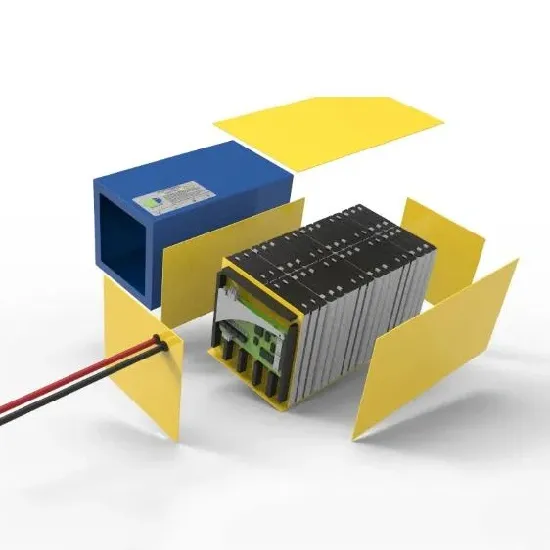

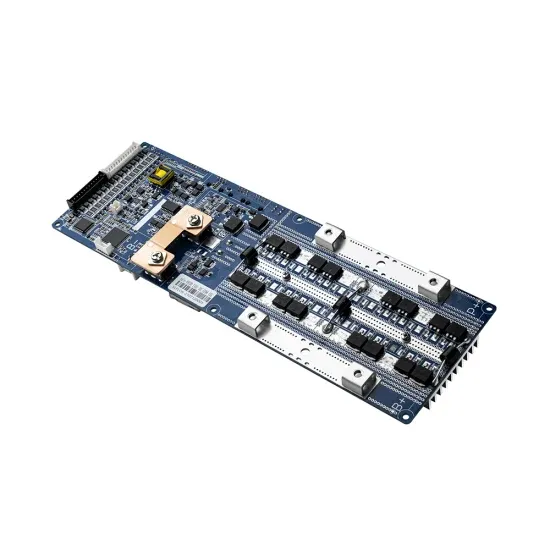

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.