High-Voltage Extruded Busbars Provide New

Aug 19, 2025 · Figure 1 – Moving towards higher integration of battery packs in electric vehicles. Overview of Busbar Design Approaches Over the years,

Georubric Engineers Pvt. Ltd. | Precision Busbar

Leading manufacturer of EV battery busbars, laser welding, and precision copper parts. Trusted for quality, innovation, and reliability in power solutions. -

Connecting battery cells: The important role of

Jul 3, 2024 · The battery pack is made up of thousands of battery cells connected together in two ways: series and parallel. This connection plays a key role in

Busbar Manufacturing

3 days ago · Our expertise in custom busbar fabrication allows us to develop innovative, space-saving designs that seamlessly integrate into battery packs, switchgear, control panels, and

10 Mistakes and How to Prevent Battery Busbar

May 14, 2025 · Battery busbar design failures are often overlooked, yet they can lead to catastrophic results like thermal runaway. Discover 10+ common

Sorting Busbar Choices for Electric Vehicle

As an example, the ROLINX Hybrid from Rogers Corp., Power Electronics Solutions is a laminated busbar that combines power and signal paths in a

Infini-Cell: Bus Bar for Battery Cell Interconnection

May 7, 2021 · Energy storage is a challenging market with continuous developments in technologies and new constraints. New battery modules are sources of technical challenges

Battery Busbar vs Traditional Cable: Which is the

In battery pack design and electrical engineering, one of the most critical decisions is how to connect the cells together: Battery Busbar vs Traditional

Busbar to Cell Connectors

Busbar to cell connectors are physically different for each cell format. All need low electrical resistance and good mechanical integrity.

Connection Parts in BEV Battery Packs

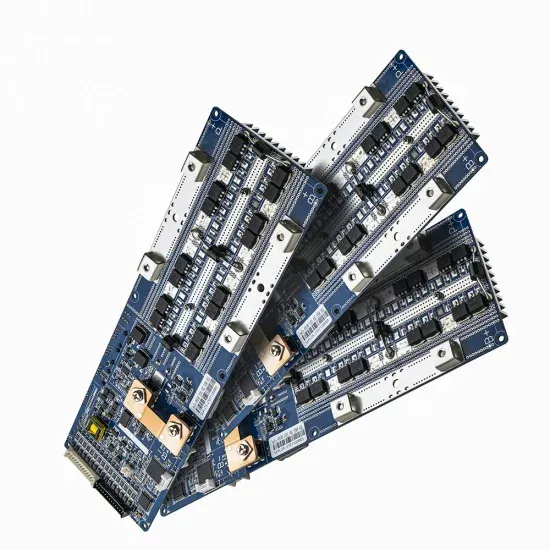

Apr 24, 2024 · Connection inside the high-voltage battery pack requires many connection parts, including a battery wiring module, which connects batteries and transmits battery information,

Busbars

Busbars are the main electrical connections between cells, modules and connect all of the HV system to the outlet connector. Normally made from copper or aluminium. Careful

Battery Bus Bar vs Battery Cable: A

Jul 12, 2024 · A battery bus bar is a robust metallic strip or bar that connects multiple battery cells within a battery pack or links various power distribution

Busbar design application note

May 15, 2023 · In battery packs for electric mobility, a busbar is used to connect battery cells or modules. In automotive battery packs, busbars are used to connect battery modules together.

Measuring Busbar Weld Resistance in Battery Packs

Jun 8, 2022 · Electric vehicles are breaking through into mainstream automotive sales with many governments and companies pledging full electric vehicle conversions in the 2020s. The

Battery Pack Busbars

Battery Pack Busbars Smart monitoring busbar solutions for battery packs MERSEN smart monitoring busbars are an innovative concept which

Busbar choices for EV power distribution

Jan 28, 2017 · As an example, the ROLINX Hybrid from Rogers Corp., Power Electronics Solutions is a laminated busbar that combines power and signal

High-Voltage Copper/Aluminum Busbars in Battery Packs

Jun 17, 2025 · Insulation: Wrap with polymer PI film or dip-coat for insulation. Copper Busbar Testing For battery pack copper busbars, the following tests ensure compliance and quality:

What is Bus Bar PCB for Battery? & High current

Jan 10, 2025 · The battery busbar PCB is a circuit board used for battery pack connection and management. It is mainly composed of signal acquisition

lithium ion

Feb 24, 2022 · What factors should we consider for designing bus bars for cell terminals? Suppose I have LFP battery pack made up of 9 cells in series each

Single Side 21700 Busbars

Mar 29, 2022 · The single side 21700 busbar is used in the Lucid Air battery design and in the Tesla Model 3. This approach can simplify the busbar

Key Benefits of Using Electric Vehicle Busbars

1 day ago · What are electric vehicle battery busbars? In previous articles, we dove deep into discussions on EV batteries: their unique design, how they are manufactured, and how they

High-Voltage Copper/Aluminum Busbars in Battery Packs

Jun 17, 2025 · Currently, the widespread adoption of 800V high-voltage platforms in new energy vehicles has made the copper/aluminum busbars within battery packs critical components.

How to Pick Bus Bar Dimensions

Jul 18, 2020 · Measuring 1/64″ thick steel sheet metal bus bars. How To Pick Bus Bar Width The width of a bus bar is arguably one of the most straight forward

Automotive battery pack manufacturing – a review of battery

Mar 1, 2020 · Automotive battery packs used for electromobility applications consist of a large number of individual battery cells that are interconnected. Interconnection of the battery cells

Busbar design application note

May 15, 2023 · In battery packs for electric mobility, a busbar is used to connect battery cells or modules. In automotive battery packs, busbars are used to connect battery modules together.

In-depth evaluation of laser-welded similar and dissimilar

Oct 1, 2021 · Abstract A recent increase in the use of electric vehicles demands an efficient and faster joining process for making electrical interconnects within the battery pack. The choice of

How to Choose the Right Battery Busbar for Your System

Aug 19, 2025 · Will the busbar be exposed to heat, moisture, or vibration? For instance, Wellgo''s nickel-plated copper busbars are designed for high-current EV packs with strong anti

Aluminium

Electrical grade aluminum busbar material also known as ec grade aluminum busbar. Compared to copper busbars aluminium offers a weight and cost

Optimizing Busbars for Advanced Applications

Apr 3, 2023 · packs as interconnects for battery modules. To support fast charging, busbars have become a vital part of the charging harness. They also make sense wherever high power is

The role of busbars in connecting battery cells

Aug 24, 2024 · Busbars play an important role in connecting battery cells in electric vehicle batteries. Thanks to their outstanding advantages, busbars

Optimizing Busbars for Advanced Applications

Dec 21, 2022 · As automakers have continued to ramp up their EV production, it has become clear that a lot must go into product and process design to create

A Guide to Electrical Busbars: Common Uses

Aug 6, 2025 · An electric busbar (also written as bus bar) is a metallic bar, strip, tube, or rod that conducts current from one place to another in a safe manner

Battery Pack Busbar Design Optimization

Jul 15, 2025 · Optimizing busbars for battery packs requires balancing electrical, thermal, and mechanical performance. Unlike simple conductors, modern busbars must handle pulsed

How Copper-Nickel Busbars Work in Lithium-Ion

Feb 23, 2025 · A copper-nickel busbar is a metallic strip or bar used to conduct and distribute electricity efficiently across battery cells in a pack. It consists of:

Battery Pack Busbars: Aluminum vs. Copper

May 17, 2025 · Understanding these trade-offs helps designers optimize busbar geometry, joining methods, and system integration. This article provides an in

6 FAQs about [Battery PACK Busbar]

How to optimize busbars for battery packs?

Optimizing busbars for battery packs requires balancing electrical, thermal, and mechanical performance. Unlike simple conductors, modern busbars must handle pulsed currents up to 10x their rated capacity while surviving vibration, thermal expansion, and decades of operation. Let’s dissect the four pillars of effective design:

What is a battery pack busbar?

1. Introduction Battery pack busbars form the critical electrical arteries of modern energy-storage systems.

What is a busbar used for?

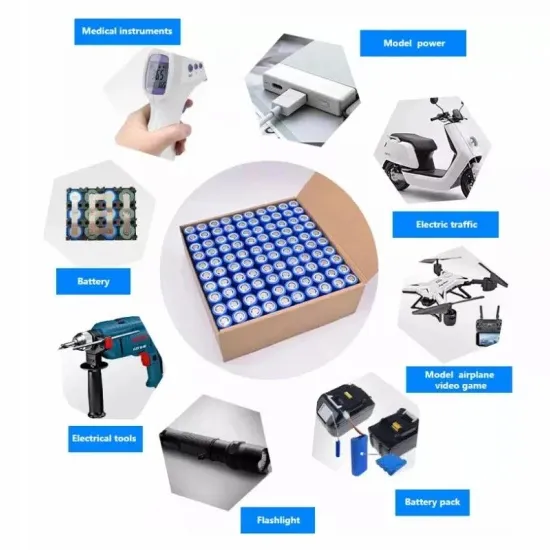

In battery packs for electric mobility, a busbar is used to connect battery cells or modules. In automotive battery packs, busbars are used to connect battery modules together. Busbars are made of copper. In a schematic, a very small resistance represents the busbar. Busbars typically have very low impedance. Figure 1. Busbar example

How does a battery busbar work?

This helps to minimize internal resistance, enhance conductivity and ensure voltage balance between the battery cells. At the module level: The busbar connects the modules together, forming a larger conductive network. This allows the current to be distributed evenly to all modules, ensuring the performance of the entire battery pack.

What are the advantages of using busbar in battery cell connection?

Advantages of using busbar in battery cell connection Effective conduction: Busbar is made from good conductive materials such as copper or aluminum, helping to minimize power loss due to the Joule-Lenz effect.

Why do EV batteries need busbars?

High Voltage Handling: Designed to handle the high-voltage requirements of EV battery systems, busbars ensure efficient power delivery and safety. As EV manufacturers aim to reduce charging times, busbars enable efficient power flow to accommodate higher charging speeds.

Industry Information

- Uh the inverter turns to 220

- Slovenia outdoor energy storage solution

- Factory price incomer breaker in Namibia

- Swiss Electric Group Energy Storage Project

- Replacing lithium batteries for power tools in North Macedonia

- Cheap wholesale sf6 circuit breaker supplier

- Sodium ion battery and communication base station alkaline reaction

- Energy storage power consumption limit

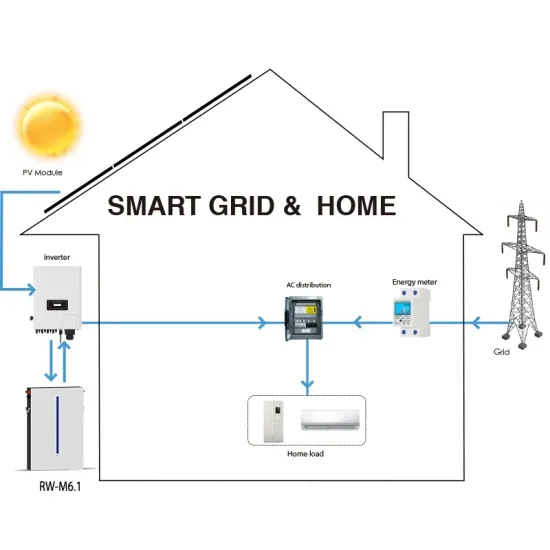

- Shanghai rooftop photovoltaic energy storage project

- Apia Solar Power System

- How to choose a suitable lithium battery pack

- PV inverter operating load range

- Wifi grid-connected inverter

- Tehran portable energy storage battery customization

- Solar air conditioning merchants

- Main brands of energy storage inverters

- Power storage feedback system

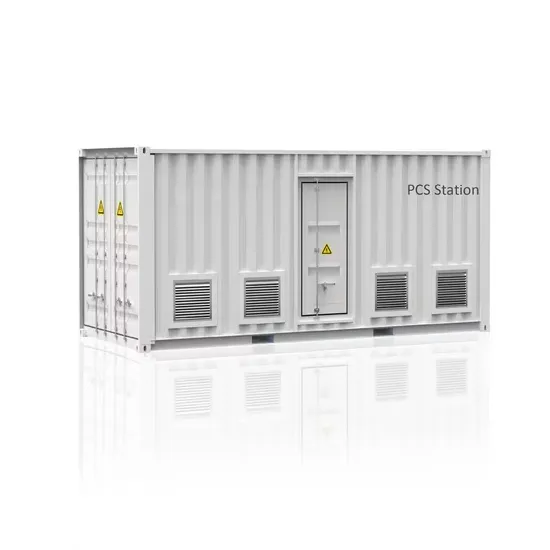

- Podgorica prefabricated energy storage container

- Peru outdoor power supply custom manufacturer

- Wholesale battery and storage in Lisbon

- Cook Islands integrated signal tower base station photovoltaic

- Container energy storage station in Gothenburg Sweden

- Tbilisi 5g base station electricity price per kilowatt-hour

Commercial & Industrial Solar Storage Market Growth

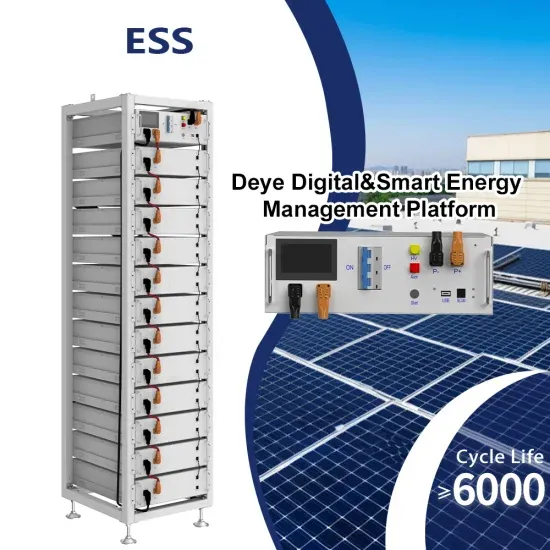

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.