Experimental, economic and life cycle assessments of

Mar 15, 2022 · Experimental, economic and life cycle assessments of recycling end-of-life monocrystalline silicon photovoltaic modules Mitchell Shyan Wei Lim a, Dong He a, Jasmine

Assessing the Viability of Solar and Wind Energy

Jun 14, 2024 · Twelve carefully chosen locations in Libya were used to assess the performance of 67 PV solar modules, 47 inverters, five different types of CPS, and 17 wind turbines using the

LONGi Sets a New World Record for

Apr 15, 2025 · This achievement pushes the boundaries of monocrystalline silicon photovoltaic cell efficiency to new heights. In November 2022, LONGi set a

Performance analysis of PV Solar Panels Augmented by

Jan 29, 2025 · Under Elbieda''s climatic conditions, as well as to investigate the fundamental effect of cell temperature on the performance of monocrystalline modules with a mirror reflector.

Atlas of PV Solar Module Technologies Across Libyan

Dec 13, 2022 · The outcome power from a PV panel is influenced by several parameters such as weather condition (solar irradiance, air temperature, wind speed, rain, sand storms), and the

Environmental impact assessment of the manufacture and

Sep 10, 2024 · Subsequently, we performed a life cycle assessment of Chinese silicon N-type- and P-type PV modules. The research system encompassed the production processes for

Environmental impact of monocrystalline silicon photovoltaic modules

Jun 30, 2025 · The most promising N-type TOPCon monocrystalline silicon photovoltaic module is examined through the life cycle environmental impact assessment, and focus is placed on

Characteristics of Crystalline Silicon PV Modules

Jan 21, 2022 · Single crystalline silicon (also known as monocrystalline silicon) and multi-crystalline silicon (also known as polycrystalline silicon) are two

Experimental comparison between Monocrystalline,

May 11, 2022 · PV cells are made from semiconductors that convert sunlight to electrical power directly, these cells are categorized into three groups depend on the material used in the

Environmental impact of monocrystalline silicon photovoltaic modules

Jun 30, 2025 · The most promising N-type TOPCon monocrystalline silicon photovoltaic module is examined through the life cycle environmental impact assessment, and focus is placed on

An introduction to solar Monocrystalline Modules

Feb 22, 2012 · Monocrystalline solar modules are made from many smaller solar cells, each from a single wafer of silicon, so they appear smooth and even.

A Technical and Economic Feasibility Study for on-Grid Solar PV

Jul 12, 2023 · In this paper, the HOMER Pro Renewable Energy Modeling Software was used to conduct a technical evaluation of a grid-connected solar PV system''s economic viability, where

Monocrystalline Solar Modules for PV Projects

3 days ago · Targray''s extensive portfolio of high-efficiency monocrystalline solar modules is built to provide EPCs, installers, contractors and solar PV

A Comparative Analysis of the Efficiency of

Nov 19, 2024 · ltaic cells. Commercially available photovoltaic technologies consist: monocrystalline silicon, and polycrystalline silicon. The main performance parameters of the

DESIGN AND SIMULATION ANALYSIS OF 100MW GRID

Sep 14, 2022 · Solar photovoltaic (PV) plants will play a significant role in the energy transition and the mix of energy sources in Libya. This article is a study conducted to investigate the

Monocrystalline silicon solar energy specifications

What is a Monocrystalline Solar Module? Monocrystalline solar modules are panels assembled using ''''mono'''' cells - solar cells composed of single-crystal silicon. The single-crystal

Material intensity and carbon footprint of crystalline silicon module

Feb 1, 2024 · The solar photovoltaics (PV) market has been booming to meet the global energy demand and to reduce the carbon emissions from energy production. Among all the PV

Environmental impact assessment of monocrystalline silicon

Jan 20, 2016 · Life cycle assessment on monocrystalline silicon (mono-Si) solar photovoltaic (PV) cell production in China is performed in the present study, aiming to evaluate the

Performance of solar photovoltaic modules under arid climatic

Nov 1, 2018 · Photovoltaic panels and concentrated solar thermal power are the most well-established technologies used to convert solar energy into electricity. Using photovoltaic (PV)

Libya monocrystalline silicon photovoltaic modules

The reliability of crystalline silicon PV modules has improved dramatically over the years [143–145]. Module warranties of 25 years are now common. There are two types of thin-film

Monocrystalline solar panels: the expert guide

Jul 25, 2025 · What are monocrystalline solar panels? Monocrystalline solar panels are made with wafers cut from a single silicon crystal ingot, which

Monocrystalline Silicon

20.3.1.1 Monocrystalline silicon cells Monocrystalline silicon is the most common and efficient silicon-based material employed in photovoltaic cell production. This element is often referred

Crystalline Silicon Photovoltaics

Crystalline Silicon Photovoltaics Characteristics of crystalline silicon photovoltaics Crystalline silicon photovoltaics is the most widely used photovoltaic

The difference between monocrystalline silicon

May 24, 2024 · The magical silicon wafer that converts solar energy into electrical energy is the core of photovoltaic technology. Today, let''s take a closer look at

Optimization of monocrystalline silicon photovoltaic

Jun 11, 2025 · Monocrystalline silicon photovoltaic modules represent a pivotal component in the solar PV manufacturing value chain. Their production process involves assem-bling

Monocrystalline silicon: efficiency and

Sep 3, 2018 · Compared to polycrystalline ingot molding, monocrystalline silicon production is very slow and expensive. However, the demand for

Libya Crystalline Silicon Photovoltaic PV Market (2025-2031)

6Wresearch actively monitors the Libya Crystalline Silicon Photovoltaic PV Market and publishes its comprehensive annual report, highlighting emerging trends, growth drivers, revenue

A Case Study on the Performance Degradation of a

Abstract- The degradation of used modules in photovoltaic (PV) systems is a major problem for module manufacturers, owners, and researchers due to their exposure to different climatic

Solar Cells and Modules

Polycrystalline Silicon Photovoltaic (PV) Cells Polycrystalline or multi crystalline silicon PV cells are made from cast square ingots — large blocks of molten

6 FAQs about [Libya monocrystalline silicon photovoltaic modules]

How many PV solar modules are there in Libya?

Twelve carefully chosen locations in Libya were used to assess the performance of 67 PV solar modules, 47 inverters, five different types of CPS, and 17 wind turbines using the System Advisor Model (SAM) dynamic simulation tool.

Is Libya a good place to use wind and solar energy?

Libya has a wide range of temperatures and topographies, making it a promising place to use wind and solar energy. This research evaluated many technologies available in the global market, including wind energy, concentrated solar power (CSP), and photovoltaic (PV) solar, with the goal of localizing the renewable energy business.

How much solar radiation does Libya receive a year?

Libya, located in the solar belt known for its extraordinarily strong solar radiation, has an average horizontal solar radiation of around 2500 kWh/m 2 /yr, which is similar to the direct normal irradiance (DNI). The nation receives more than 3500 h of sunlight each year, particularly in the central and southern areas (Fig. 2) [39, 40].

Do wind turbine models perform well in climatic conditions in Libya?

Using the SAM software, the study tested the performance of 17 different wind turbine models in a range of climatic conditions at 12 different locations throughout Libyan territory. Figure 14 shows the competitive analysis of these wind turbine models visually for the city of Al-Jufra in a column format.

Should Libya build a replacement power plant?

Libya produces 0.967 kg CO 2 /kWh of CO 2. Therefore, building a substitute power plant with a 1000 MW capacity and a 40% capacity factor would stop about 3.82 million tons of CO 2 from being released into the atmosphere, saving an estimated $286.329 million in carbon tax each year.

What are the different types of crystalline silicon cells?

The first category includes wafer-based crystalline silicon cells, such as monocrystalline silicon (M-Si), polycrystalline silicon (P-Si), and string ribbon. Despite their great efficiency, these cells are generally pricey.

Industry Information

- Panama Liquid Flow Energy Storage Battery

- Lobamba photovoltaic panel grid-connected manufacturer

- Photovoltaic glass strengthens

- Slovenia 5G communication base station energy management system project

- Backup energy storage battery in Toronto Canada

- Avaru Solar PV Panel Inverter

- Bulgaria Outdoor Communication Battery Cabinet Factory 372KWh

- Double glass and single glass modules

- Majuro new supercapacitor price

- Photovoltaic panel silicon size

- Desert power generation and energy storage

- How much does a microgrid energy storage system usually cost

- Sanaa communication base station lead-acid battery photovoltaic power generation outdoor unit

- Guatemala City AP Telecom Battery Cabinet

- How much does the Palestinian phase change energy storage system cost

- Nauru s largest battery energy storage battery manufacturer

- 318 How many degrees of outdoor power supply should I buy

- 12V 220V 200W inverter

- Communication base station power supply communication protocol

- Ask for the price of a new inverter

- 30kw hybrid inverter in China in Gambia

- Energy storage production and manufacturing project landed

- Al hassan switchgear for sale in Kyrgyzstan

Commercial & Industrial Solar Storage Market Growth

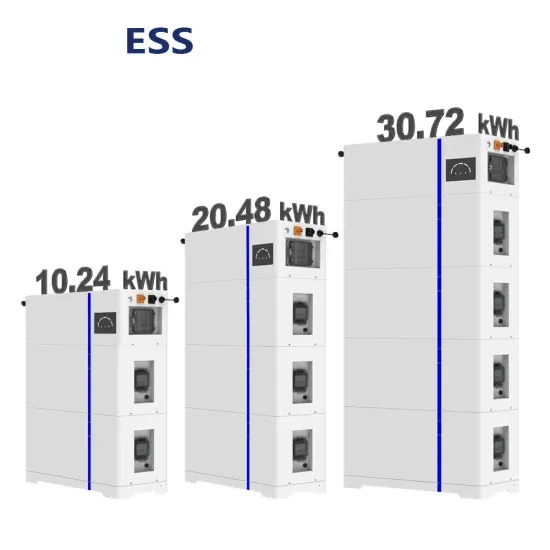

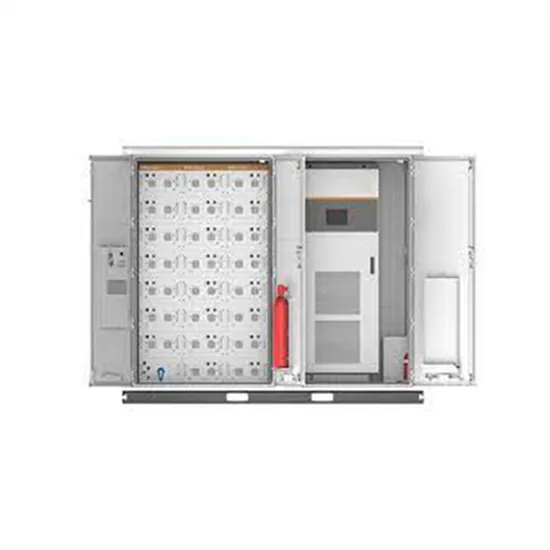

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.