Fracture Probability, Crack Patterns, and Crack Widths of

Oct 1, 2018 · We experimentally analyze the position and opening behavior of cracks in multicrystalline silicon solar cells laminated in standard-sized frameless modules during

Life-cycle assessment of multi-crystalline photovoltaic (PV)

Jan 1, 2015 · It considers the primary energy demand, energy payback time (EPBT), and environmental impacts, such as global warming potential and eutrophication, over the entire

Types of PV Panels – Solar Photovoltaic

Compared to monocrystalline silicon, multicrystalline silicon PV cell is moderately efficient with a market efficiency ranging from 11-14%, as a result, the cost of

A comparative life-cycle assessment of photovoltaic

Jan 1, 2018 · Three roof-integrated PV systems using different p-type multi-Si PV technologies (cell or module) are investigated: (1) Al-BSF (aluminum back surface field) solar cells with the

Long-term reliability of silicon wafer-based

With the newer techniques of manufacturing crystalline Si wafer-based PV modules and efficient power converter design, it is possible to make the PV

Multicrystalline Solar Cells for PV Manufacturers

5 days ago · Our multicrystalline solar cells are made with best-in-class PV materials to help solar module manufacturers and solar suppliers enhance

A comparative life-cycle assessment of photovoltaic

Apr 17, 2024 · A comparative life-cycle assessment of photovoltaic electricity generation in Singapore by multicrystalline silicon technologies | ScholarBank@NUS

Crystalline Silicon Module

5.4.1 Crystalline silicon modules Crystalline silicon (c-Si) modules dominate the PV market with a 95% share [73]. The cells are available in multicrystalline (multi-Si) and mono-crystalline

Characterization of Multicrystalline Silicon Modules with

Sep 30, 2013 · We performed accelerated lifetime testing of multicrystalline silicon PV modules in 85°C/85% relative humidity (RH) and 45°C/30% RH while placing the active layer in either

A comparative life-cycle assessment of photovoltaic

Jan 1, 2018 · Abstract This paper presents a comparative life-cycle assessment of photovoltaic (PV) electricity generation in Singapore by various p-type multicrystalline silicon (multi-Si) PV

A Quantitative Comparison Between Double Glass Photovoltaic Modules

Jul 27, 2017 · Study about the effect of antireflection coating stacks (TiO2–SiO2/SiO2/SiNx) on the performances of multicrystalline silicon solar cells under the encapsulation condition

Silicon Solar Cell

Silicon is also useful in manufacturing solar PV technologies, such as mono-crystalline and poly-crystalline silicon PVs. Silicon has been proven to have field stability; hence, crystalline silicon

Low Temperature Solar Cell Encapsulation with Novel

Mar 29, 2023 · This type of material is used as an alternative to pre-shaped aluminum or silicone foam spacers in the fabrication of insulated glass, but also as edge material for thin-film PV

Menghong WANG | Doctor of Philosophy | Case Western

Characterization of front contact degradation in monocrystalline and multicrystalline silicon photovoltaic modules following damp heat exposure Article Nov 2021 Nafis Iqbal Dylan Colvin

A comparative life cycle assessment of silicon PV modules:

Sep 15, 2021 · This study will be useful for future PV LCA practitioners as it comprehensively addresses the potential environmental impact of single-crystalline silicon glass-glass modules

Comparative Life Cycle Assessment of Photovoltaic Systems

Jul 31, 2024 · With global movement toward renewable energies, photovoltaic technologies are rapidly developing toward a greener electrification and net zero emissions plans, utilizing the

A comparative life-cycle assessment of photovoltaic

Jan 1, 2018 · The environmental benefits (in terms of EPBT and GHG emissions) of PV electricity generation can be significantly enhanced by using frameless double-glass PV module design.

Characteristics of Crystalline Silicon PV Modules

Jan 21, 2022 · Single crystalline silicon (also known as monocrystalline silicon) and multi-crystalline silicon (also known as polycrystalline silicon) are two

Modelling and experimental investigations of microcracks in

Jan 1, 2020 · One of the predominant failure modes that appears in the crystalline silicon (c-Si) PV technology is the cell cracking that may damage the mechanical integrity of the PV module

Corrosion effects in bifacial crystalline silicon PV modules

Jul 1, 2023 · This study addresses the influence of different encapsulation materials on performance losses in bifacial PV modules after extended damp heat testing.

Effect of materials and design on PV cracking under

Nov 1, 2022 · This section describes the geometrical development and validation of FE models for three PV module architecture designs, for a 60-cell crystalline silicon glass-backsheet module,

Development of high‐performance

The low cost and high quality of multicrystalline silicon (mc-Si) based on directional solidification has become the main stream in photovoltaic (PV)

Double-glass PV modules with silicone encapsulation

May 21, 2024 · In this paper a glass–glass module technology that uses liquid silicone encapsulation is described. The combination of the glass–glass structure and silicone is

A Quantitative Comparison Between Double Glass Photovoltaic Modules

Jul 27, 2017 · The use of half-size silicon (Si) wafer solar cells in photovoltaic (PV) modules can enhance the output power compared to full-size Si wafer solar cells. In this paper, an optimal

Multicrystalline Solar Modules for PV Projects

6 days ago · Targray''s portfolio of high-efficiency multicrystalline solar modules is built to provide EPCs, installers, contractors and solar PV developers with

Impact of Cracks in Multicrystalline Silicon Solar Cells on PV Module

Sep 8, 2015 · In this paper, we present a methodology to exploit the crack statistics of solar cells in photovoltaic (PV) modules assessed in field for simulating the power output of PV modules

High performance double-glass bifacial PV modules

Oct 5, 2016 · Double-glass structure shows a loss of ~ 1.30% compare to the glass/backsheet structure under STC measurements. J. P. Singh, et al. "Comparison of Glass/glass and

Material intensity and carbon footprint of crystalline silicon module

Feb 1, 2024 · The growing solar photovoltaic (PV) installations have raised concerns about the life cycle carbon impact of PV manufacturing. While silicon PV modules share a similar framed

Multicrystalline single-sided double-glass photovoltaic modules

The Difference Between Double-glass and Single The main difference between double-glass photovoltaic modules and single-sided glass solar panels lies in their construction and design,

The Performance of Double Glass Photovoltaic Modules

Sep 1, 2017 · In recent years, with the rapid development of the photovoltaic industry, double glass module as a high reliability and high weather resistance product is favored by many PV

CO2 EMISSIONS OF SILICON PHOTOVOLTAIC MODULES

Sep 27, 2022 · The CO2 emissions of the produced electricity, excluding balance of system (BoS), amount to 13-30 g CO2-eq/kWh, depending on the production location and electricity

High-efficiency Module,Longi solar module

3 days ago · LONGi High-efficiency solar Module, widely adopting PERC solar cells technology, Half-cut Module Technology and Bifacial PV

Crystalline Silicon Solar Cell and Module Technology

Jan 1, 2018 · The aim of this chapter is to present and explain the basic issues relating to the construction and manufacturing of PV cells and modules from c-Si. This includes the basic

6 FAQs about [Multicrystalline silicon double glass photovoltaic modules]

What is a double glass c-Si PV module?

Recently several double-glass (also called glass–glass or dual-glass modules) c-Si PV modules have been launched on the market, many of them by major PV manufacturers. These modules use a sheet of tempered glass at the rear of the module instead of the conventional polymer-based backsheet. There are several reasons why this structure is appealing.

Are double-glass PV modules durable?

Double-glass PV modules are emerging as a technology which can deliver excellent performance and excellent durability at a competitive cost. In this paper a glass–glass module technology that uses liquid silicone encapsulation is described. The combination of the glass–glass structure and silicone is shown to lead to exceptional durability.

Does p-type multi-crystalline silicon (multi-Si) PV technology dominate the PV market in Singapore?

In this study, we perform a comparative LCA of PV electricity generation in Singapore by various p-type multicrystalline silicon (multi-Si) PV technologies, which is forecasted to maintain their dominance (~50%) in the PV market in the next 10 years .

Why should you choose a multicrystalline solar cell?

Our high-efficiency multicrystalline solar cells are trusted by PV manufacturers worldwide and are engineered to meet the evolving requirements of the solar photovoltaics industry. They are built using the best-in-class raw materials and are subject to strict quality control. Our multicrystalline PV cells deliver the following benefits:

What are the benefits of multicrystalline PV cells?

Our multicrystalline PV cells offer several benefits: They deliver high Cell-To-Module ratio through precise cell conversion efficiency sorting. These cells are classified efficiency grade by both minimum power and current. Additionally, they provide excellent electrical long-term stability and reliability. Built using the best-in-class raw materials and subject to strict quality control.

Why is LCA conducted on multi-crystalline silicon photovoltaic systems in China?

LCA is conducted on the multi-crystalline silicon photovoltaic systems in China. Multi-Si production is the most contributor to the energy demand and environmental impacts. Compared to other power generation systems in China, PV system is more environmentally friendly. Areas with higher solar radiation are more suitable for installing PV systems.

Industry Information

- South American power storage vehicle manufacturers

- How much is the price of base station batteries in the Marshall Islands

- Monaco s new solar photovoltaic panels

- Micro inverter overvoltage protection

- Chad Energy Storage Equipment

- Huawei Japan Osaka Energy Storage Charging Pile Brand

- Differences between different flow batteries

- Smart solar inverter in China in Singapore

- How to store energy outdoors

- EK mobile outdoor power supply advantages

- Malawi crystalline silicon photovoltaic curtain wall

- Tonga Temporary Container Wholesale

- Best solar powered battery charger manufacturer

- What does the ems energy storage management system include

- 16kw sunsynk inverter factory in Uganda

- Communication 5g base station panel settings

- Best high quality 1000 va inverter Seller

- New zinc-bromine energy storage battery

- South Asia Solar Power System Solution

- Factory price serket breaker in Albania

- Lithium battery bms data

- Uninterruptible Power Supply Solution in Surabaya Indonesia

- Which energy storage system cae is better

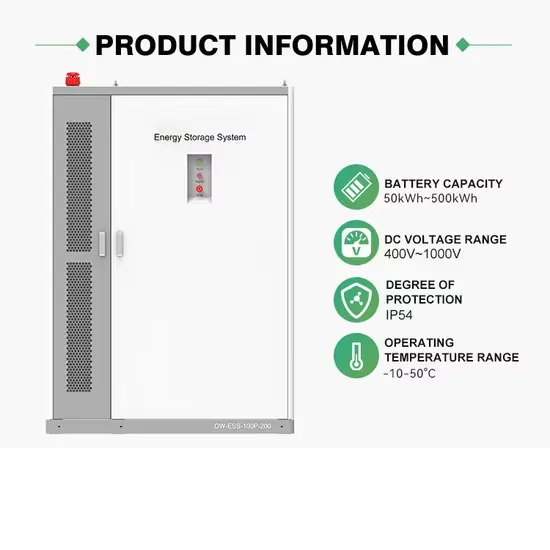

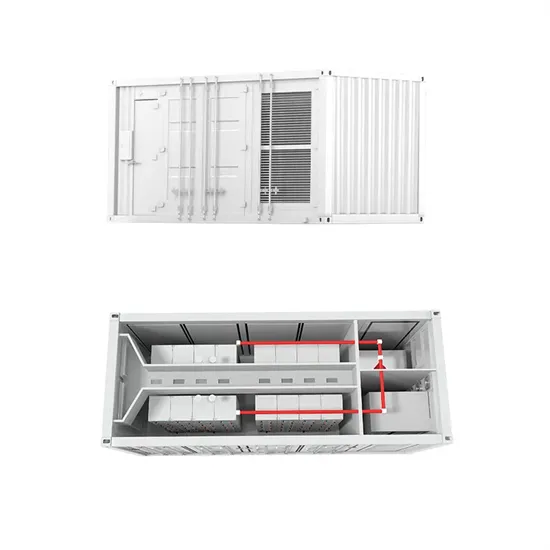

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

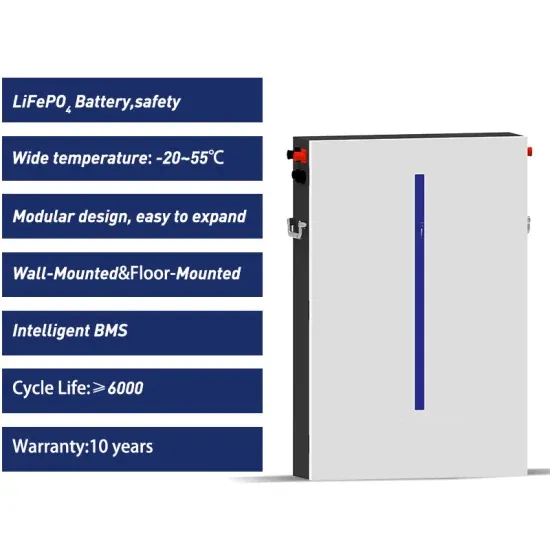

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.