Traction inverter

Mar 5, 2025 · In electric vehicles, the traction inverter connects the high voltage battery pack and the motor, and adjusts the frequency and amplitude of the

The Critical Role of Inverter Technology in

Apr 28, 2025 · As the global automotive industry shifts toward electrification, the role of inverter technology has become increasingly central. While much

电动汽车 (EV)牵引逆变器 | NXP 半导体

Aug 15, 2025 · PDF May 2, 2024 版本更新 3 EV Power Inverter Control Reference Design Factsheet[RDPWRINVERTERFS] PDF Nov 30, 2022 版本

Everything You Need to Know About Inverters:

May 10, 2024 · Unlock the potential of power supply with our comprehensive guide on all about inverters - discover types, benefits, and tips for the perfect

Traction Inverters for Electric Vehicles

Jan 25, 2025 · Traction inverters are a crucial component of electric vehicles (EVs), responsible for converting direct current (DC) power from the battery

Run An AC Motor With Battery: DIY Inverter-Free Solutions

May 30, 2025 · To run an AC motor with a battery, use an inverter or motor controller. These devices convert the battery''s DC voltage into the AC voltage needed by the

A technical review of modern traction inverter systems used

Nov 1, 2023 · This article presents a comprehensive review of modern traction inverter systems, their possible control strategies, and various modulation techniques deployed in electric

1.5kW GaN Inverter for Battery-Powered Motor Drive

Jul 25, 2024 · 1.5kW GaN Inverter for Battery-Powered Motor Drive Applications GaN transistors and ICs increase power density in motor drive applications. An optimal lay-out approach

How Inverters Work with Batteries: A Beginner''s

Mar 4, 2025 · An inverter changes DC power from a 12 Volt deep-cycle battery into AC power. The battery discharges while the inverter provides power. You

Power Electronics

Power Electronics BorgWarner is a leading supplier of advanced electrification technologies for Electric and Hybrid vehicles. Our portfolio includes a full

Powering An AC Motor Of Battery: Can You Run It Without An Inverter

April 15, 2025 by Karim Ul Hasan To run an AC motor with a battery, use an inverter or motor controller. The inverter changes the battery''s DC voltage into AC voltage needed by the motor.

HEV/EV Traction Inverter Design Guide Using Isolated

Apr 1, 2023 · The three legs of the inverter convert the DC battery voltage into three phases of AC voltage and current to drive the motor. Two current measurements and a position

What Is an Inverter in an Electric Vehicle?

Aug 9, 2023 · An inverter is a device that converts direct current (DC), which is supplied from a battery, into alternating current (AC). A motor in an electric vehicle runs on this alternating

EV inverters: Key to motor control

Oct 13, 2023 · What is driving development of EV inverters? EV inverters, also known as traction inverters, convert the dc electricity from the battery into the

EV Power Electronics: Purpose of Key

6 days ago · In this comprehensive article, we shed light on the significance of individual EV powertrain components in driving the E-mobility revolution,

The Role of Inverters and Power Electronics in EV

Jul 19, 2024 · The interplay between inverters and other power electronic components ensures the efficient operation of the EV powertrain. Key

Universal Inverter – Test stands for battery packs, inverters, e-motors

Universal Inverters for testing traction inverter control algorithms. Characterizing and testing E-Motor designs for electric vehicles. Test your EV inverter designs and E-Motors with a Unico

System Solution Guide: Traction Inverters

Feb 3, 2025 · To operate, the motor depends on a traction inverter, which converts the battery''s DC power into AC power. As the core of a BEV, the traction inverter enables the torque and

Inverter for commercial vehicles

The inverter converts the direct current from the battery into the alternating current required by the electric motor. With its electronic control and

Design Priorities in EV Traction Inverter With Optimum

Apr 1, 2023 · A traction inverter also converts recuperation energy from the motor and recharges the battery while the vehicle is coasting or braking. There are several key design priorities and

Battery electric vehicles: Progress, power electronic

Nov 1, 2022 · Electric motors are replacing the energy systems mainly to improve the powertrain''s efficiency and ensure they are environmentally friendly. These novel powertrains are designed

Active Motor Simulation for Testing Automotive

Apr 13, 2021 · This article highlights testing inverters that require a battery simulation and a motor simulation.

Tesla Model 3 Teardown: Motor, Inverter, and Battery

Mar 22, 2019 · The inverter has been made smaller by adopting a new power module that is probably made of SiC (silicon carbide) steel material. For the battery, a new cell configuration

High-voltage traction inverter | Nexperia

6 days ago · With both battery electric vehicles (BEV) or plug-in hybrid electric vehicles (PHEV), transferring the stored energy from the high-voltage (400 /

Get the best Inverter Battery by Okaya

All-New Advanced Inverter Batteries Okaya''s Advanced Inverter Batteries are engineered to deliver dependable, long-duration power backup for homes, offices, and commercial spaces.

Drive Train Cooling Options for Electric Vehicles

Jul 11, 2024 · Battery thermal management is the most critical topic in electric vehicles and affects overall vehicle reliability, performance, and price levels. Traction inverters, also commonly

A closer look at multilevel traction inverters

Mar 20, 2025 · In this topology, each bridge switch can connect its output terminal (i.e. motor phase winding) either to the positive or the negative rail of a voltage

Battery Emulator – Test stands for battery packs, inverters, e-motors

This advanced E-Motor emulator is expertly crafted for testing vehicle traction inverters safely and efficiently without using an actual production E-Motor, thereby eliminating the risk of costly

Traction Motor Inverter

6 days ago · Traction motor inverters convert DC power from an on-board high-voltage battery (typically 200–800V) into AC power to drive the main motors of an Electric Vehicle (EV).

Electric Vehicle (EV) Traction Inverter | NXP Semiconductors

Aug 15, 2025 · The NXP EV traction inverter is a critical component in electric vehicles which is responsible for converting DC power from the battery to AC power to drive the traction motor.

HEV/EV Traction Inverter Design Guide Using Isolated

Apr 1, 2023 · The key blocks of an EV powertrain system are the electric motor, the traction inverter drive, the DC/DC converter, the Li-ion battery, the AC/DC grid-tied on-board charger

6 FAQs about [Battery Motor Inverter]

What is a traction motor inverter?

Traction motor inverters convert DC power from an on-board high-voltage battery (typically 200–800V) into AC power to drive the main motors of an Electric Vehicle (EV). Traction motor inverters control the speed and provide the torque for EV motors.

How does an electric motor inverter work?

The inverter converts the direct current from the battery into the alternating current required by the electric motor. With its electronic control and monitoring of the electric motor, it ensures a safe and demand-based electrical supply for the electric drive. Are you interested in our solutions?

How do EV inverters work?

EV inverters, also known as traction inverters, convert the dc electricity from the battery into the three-phase variable frequency ac that’s needed to drive the motor at a given speed (Figure 1). EVs use asynchronous (induction) motors or sometimes synchronous motors.

Do traction inverters work in electric vehicles?

This article presents a comprehensive review of modern traction inverter systems, their possible control strategies, and various modulation techniques deployed in electric vehicles (EVs). The traction inverter is a fundamental component in electrifying the EV drive system due to its critical functioning in a wide range of operations.

Do electric vehicles use multilevel inverters?

Although the use of multilevel inverters for traction applications has been the subject of numerous articles, not all forms of electric transportation have made use of these inverters. Two-level structures are used in the drive systems of trucks, buses, and low-voltage electric vehicles.

What makes a good EV traction inverter system?

It must deliver high power levels (from 80 to over 200 kW), withstand high temperatures and be lightweight. NXP's EV traction inverter system solution features multicore lockstep MCUs, safety SBCs, CAN, Ethernet PHY and high-voltage gate drivers to control power conversion to the traction motor with high efficiency and reliability.

Industry Information

- North Korea photovoltaic system accessories combiner box

- Belmopan Home Solar Photovoltaic Panels

- Photovoltaic energy storage carport home use

- Pakistan Power Storage

- Shanghai Energy Storage Vehicle Product Price

- Battery cabinet manufacturer for Phnom Penh computer room

- Can I bring outdoor power supply to Mexico How much does it cost

- Bhutan 80W solar street light

- Kosovo Communication Base Station Inverter Maintenance Company

- Photovoltaic glass generator manufacturers

- Average power of photovoltaic inverter

- Huawei Malaysia New Energy Storage Box

- Photovoltaic panels limit power generation

- Current power generation and energy storage equipment

- China small inverter for home in Senegal

- Later maintenance cost of energy storage cabinet

- Solar household system design

- Small photovoltaic panel wholesale manufacturers

- Philippines solar energy storage module prices

- Rcb circuit breaker for sale in Argentina

- 5G base station scenario application

- High quality factory price main switchgear Seller

- Solar power system for cabin in Namibia

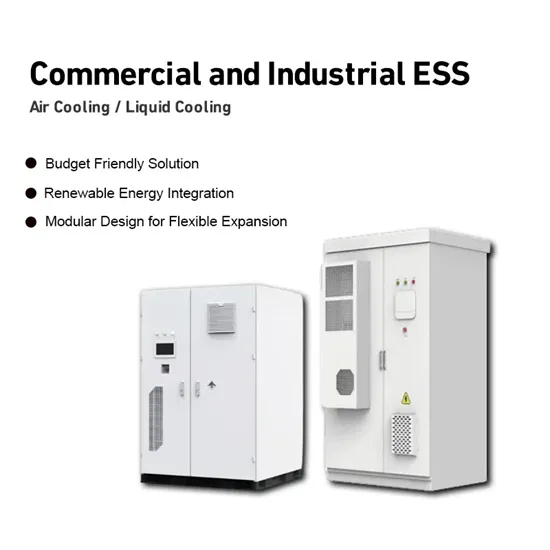

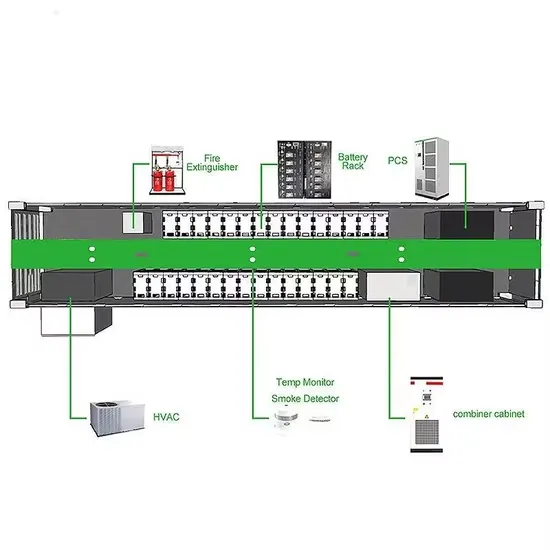

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

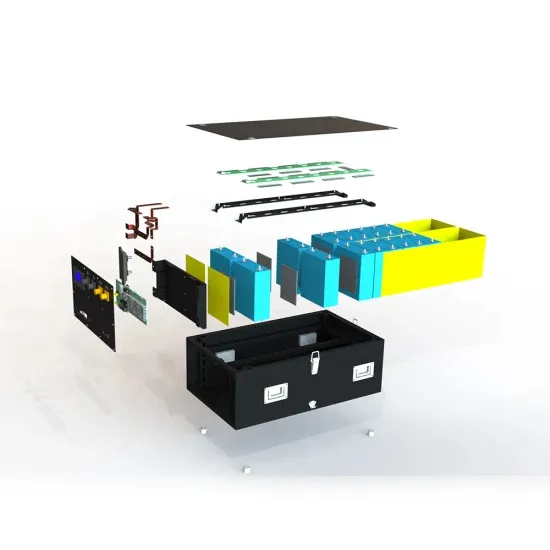

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.