Choke For Frequency Inverter

China Choke For Frequency Inverter wholesale - Select 2025 high quality Choke For Frequency Inverter products in best price from certified Chinese High Frequency Equipment

Inverter design using high frequency

Feb 27, 2021 · In which we are developing an inverter which is to be light in weight, compact and highly energy efficient. This can possible with the help of High Frequency Inverter; hence we

Inverter choke

Find your inverter choke easily amongst the 58 products from the leading brands on DirectIndustry, the industry specialist for your professional purchases.

Low Frequency High Current Power Choke Coil for Solar Inverter

Jul 13, 2025 · Low Frequency High Current Power Choke Coil for Solar Inverter, Find Details and Price about Choke Coil for Solar Inverter Solar Inverter Power Choke from Low Frequency

High Frequency Choke Inductor for PCB Motor

6 days ago · High efficiency and High Permeability. 2. High power and Low Frequency Switching. 3. High current. 4. Low power loss. 5. Low temperature

Analysis and Design of Choke Inductors for

Aug 21, 2017 · High-frequency lumped-element model of a choke inductor. Simulated frequency spectrum obtained using Fourier analysis of the choke

High-Frequency Impedance Modeling of Nanocrystalline

Aug 2, 2024 · The common-mode choke (CMC) serves as a key component in mitigating electromagnetic interference noise across various applications. High-frequency (HF)

Guide To Toroidal Chokes | Types, Selection and Applications

Toroidal chokes, also known as common mode chokes, are magnetic inductors that act as a filter to block the high-frequency noise & interference from power supply lines and allow the desired

(PDF) Simplified Design of Common-Mode Chokes for

Research indicates that higher inductance yields lower peak ground currents; for instance, using an inductance of 16.7 µH achieves noted current limits in simulations. The findings show that a

Frequency inverter basics

Frequency inverters are widely used throughout industry to provide adjustable speed control of ac motors. Although modern versions are relatively simple to

Common-mode Nanocrystalline chokes

6 days ago · Common mode choke coils block undesirable high-frequency noise typically from unshielded electronics, inverters, and motors. This noise can

DC Choke for Frequency Inverters FR-F/A800

Use the chokes to suppress interferences, to increase the degree of efficiency or when installing the frequency inverter near a trans-former with a transformer power of 500 kVA or more. If you

Ee13/Ee16/Ei40/Etd/Pq Inverter Electric PCB

3 days ago · Ee13/Ee16/Ei40/Etd/Pq Inverter Electric PCB Flyback SMPS Bobbin Power Supply Choke Inductor High Frequency Transformer, Find Details and

2mH 25A Industrial Drive Common Mode Choke THT Type

5 days ago · Coilmaster Electronics is a high-current 2mH 25A Industrial Drive Common Mode Choke THT Type, Heavy-duty nanocrystal choke for industrial automation, robotics, and

Simulation Model of Common-Mode Chokes for

May 1, 2010 · Linear and nonlinear Cauer-network models for nanocrystalline inductor cores are developed and used for circuit simulations of common

Comprehensive Guide to Chokes in Power Applications

Line Choke, Commutation Choke: AC chokes for network fundamental frequency, mainly in a three-phase design, used to improve network current load (PFC) and to reduce the steepness

Homemade PCB EGS002 Full Sine Inverter

How to make a full sinusoidal inverter using the EGS002 driver board. Supplied with 12V from a battery and output 230V AC at 50Hz with SINE wave and 500W.

EMC/EMI Filter Design with RB Common-Mode Chokes

Oct 13, 2019 · 9. Consider to use RB choke evaluation boards for a test set-up For the fast design-in of RB choke based EMC/EMI filters Schaffner offers various evaluation boards to

(PDF) Simplified Design of Common-Mode Chokes for

Switching converters are used in electric drive applications to produce variable voltage, variable frequency supply which generates harmful large dv/dt and high-frequency common mode

Choke frequency inverter

Choose from a wide selection of variable frequency driver & discover wholesale choke frequency inverter that suit various applications from small appliances to large compressors.

Chokes

Mains chokes If current peaks have to be smoothed, which can be caused by the current consumption of an inverter, for example, a line choke is connected between the supply

Input Chokes for Invertek Variable Frequency

Invertek Drives have selected a range of chokes matched to the Optidrive range to provide the best reduction in supply current harmonics whilst also providing

Common Mode Chokes Basics and Applications

Jun 29, 2022 · A common mode choke is a passive electromagnetic device that permits the passage of the desired electrical signals through data or power lines while filtering out the

Understanding Common Mode Chokes: Principles and

Where: AC/DC converters, inverters, solar panels.Why: Stops CM noise from switching circuits (kHz range) from radiating or back-feeding into the grid.Example: A 10 mH CMC in a 230 V AC

Chokes vs. Inductors | Triad Magnetics

4 days ago · As the name implies, a choke cuts off or restricts high-frequency alternating current (AC). It only permits direct current (DC) to pass through its

High Frequency Common Mode Choke Coil for UPS Power Inverter

Feb 24, 2025 · High Frequency Common Mode Choke Coil for UPS Power Inverter, Find Details and Price about Choke Choke Coils from High Frequency Common Mode Choke Coil for UPS

Chokes for AC-DC inverters

Rated RMS current with grid frequency: depending on the application, typically up to 1,000 A in our products. Depending on the solution, the components

Common Mode Choke Guide

2 days ago · A common mode choke is an inductor designed to block high-frequency noise while allowing the desired signal to pass through. It consists of two coils wound on a magnetic core,

Solar Power Inverters and EMI Filtering

Feb 1, 2023 · The inductors act as choke coils, limiting the flow of high-frequency noise, while the capacitors act as bypasses, short-circuiting the high

Technical Reference Manual

May 23, 2025 · The third stage is the inverter which converts the DC voltage back to AC voltage using IGBTs (insulated Gate Bipolar Transistors), to create a pulse width modulated voltage

Choke Product Overview

Choke Product Overview Schmidbauer GmbH manufactures a comprehensive program of chokes up to 300kHz or 2500 amperes – also for higher switching

High Frequency

Rishab Industries also design, manufacture & supply High Frequency Chokes for High Frequency applications up to 200 KHz. We have High Frequency Chokes in following types:

6 FAQs about [Inverter high frequency choke]

Which type of choke should be used in the inverter-output?

Simplified sketch to illustrate placement of common-mode choke in the inverter-output. chokes differ from standard choke design. Notably, use of be a more practical choice than wound chokes, (Fig. 2). high permeability . Amorphous and nanocrystalline mate- rials have good properties in both these aspects.

What is an input choke?

Input chokes can be used to reduce the supply line harmonic currents and voltage distortion generated by almost all inverter drives on the market today.

How useful is a choke inductor?

The measured magnitude of the inductor impedance has shown that the designed choke is useful up to 10 times the switching frequency. Waveforms of the ac component of the choke inductor current and its fundamental harmonic component in class-E inverter. High-frequency lumped-element model of a choke inductor.

Does choke inductor current cause power loss?

the dc choke inductor current is the dominant loss component. fundamental and the harmonics. Therefore, the power loss due to the harmonics in the choke inductor current can be neglected. in the shunt capacitor of the class-E inverter. The contributions of this paper are as follows. has been introduced. The procedure involves the design

What is voltage drop in a DC choke?

Voltage drop across an AC choke reduces the input voltage to the rectifier and consequently the generated DC voltage and thus the maximum voltage that can be supplied to the motor. The voltage drop is usually in the range of 2–3%. This problem is nonexistent with DC chokes.

Does a choke reduce peak current?

the choke. The damping can reduce the peak current when an ideal inductor model is used. However, when a realistic frequency-dependent model of an only increases the current. Annual Meeting, vol. 1, pp. 162–167, 1996.

Industry Information

- Benefits of Energy Storage Liquid Cooling System

- Disadvantages of small power inverters

- Solar Inverter Topologies

- Lithium iron phosphate battery energy storage container manufacturer

- Super Energy Storage Factory Product Price

- Gas fire extinguishing energy storage project

- Montevideo Energy Storage Battery

- Which part of the photovoltaic panel is the monocrystalline silicon

- Is flywheel energy storage electrochemical storage

- Kyrgyzstan Integrated Energy Storage Power Station

- The largest 24 volt inverter for home use

- Fully automatic energy storage equipment design

- Energy storage battery manufacturers to be built in the Middle East

- The impact of grid energy storage projects on the environment

- 1000w solar inverter in China in Brasilia

- Energy storage cabinet distribution worker

- The service life of flexible photovoltaic panels

- Libya grid-connected inverter

- 24v72v to 220v inverter

- Philippines container distributed photovoltaic

- Lisbon Energy Storage Project

- Guinea-Bissau s power supply helps 5G base stations

- Sophia Energy Storage Container Power Station Enterprise

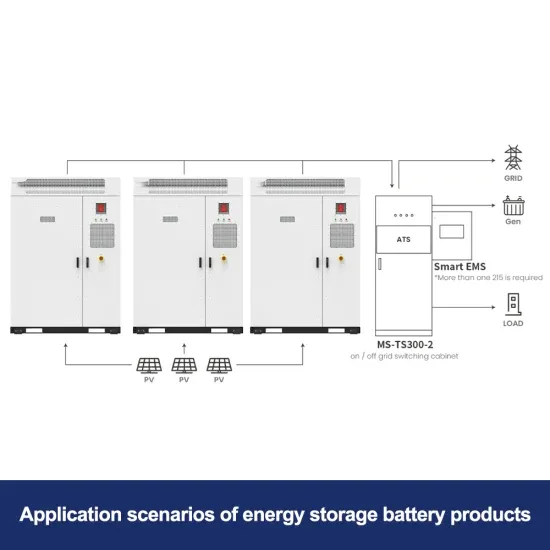

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.