What Is a Monocrystalline Solar Panel?

Aug 4, 2024 · The higher cost of monocrystalline panels is attributed to their complex manufacturing process and the use of high-purity silicon, which

Photovoltaic Basics (Part 1): Know Your PV

Aug 26, 2024 · Panels made with hetero-junction are based on three materials: monocrystalline silicon, amorphous silicon and ITO (indium oxide thin film);

Types of photovoltaic solar panels and their

Nov 6, 2017 · Instead of using silicon in crystalline form, they use a thin layer of photovoltaic material deposited on a substrate such as glass, plastic or metal.

Monocrystalline Solar Panels: 2025 Costs & How

Jun 16, 2025 · Monocrystalline solar panels are the top choice for homeowners looking for high efficiency and long-term value. Made from a single crystal of

Monocrystalline vs Polycrystalline Solar Cells and How to

Mar 12, 2025 · Monocrystalline and polycrystalline silicon solar panels With the rapid development of solar photovoltaic energy storage, its solar panel technology update iteration is also very

Silicon Solar Cell

Silicon solar cells are defined as photovoltaic devices made from crystalline silicon, which are characterized by their long-term stability, non-toxicity, and abundant availability. They

Solar panel types and differences:

The main types of solar panels on the market today are monocrystalline silicon, polycrystalline silicon and amorphous silicon solar cells. Differences between

Understanding Monocrystalline Solar Panels

Apr 10, 2024 · Monocrystalline solar panels are made from a single crystal of silicon, which is a semiconductor material that can convert sunlight into

Monocrystalline Solar Panels: Advantages and

Good silicon feedstock is expensive (although less so in 2010 then it has been for a a while) and the cost of making a single pure crystal is time-comsuming and

Which is Better, Polycrystalline or

Aug 7, 2023 · The advantage of using monocrystalline photovoltaic panels is the greater efficiency, even in low light conditions, such as cloudier days.

Photovoltaic (PV) Cell Types | Monocrystalline,

5 days ago · The article provides an overview of the main types of photovoltaic (PV) cells, including monocrystalline, polycrystalline, and thin-film solar

Analysis of the Advantages and Disadvantages of Monocrystalline Silicon

Although the average conversion efficiency of monocrystalline cells is about 1% higher than that of polycrystalline silicon cell, because monocrystalline cells can only be made into a quasi

Monocrystalline silicon

4 days ago · Monocrystalline silicon can be used to generate electricity within solar panels because of the observation of the photovoltaic effect. The photovoltaic effect is caused by the

The Pros and Cons of Monocrystalline Solar Panels

5 days ago · One type of solar panel that has gained significant attention is the monocrystalline solar panel. Monocrystalline solar panels are known for their

Experimental comparison between Monocrystalline,

May 11, 2022 · PV cells are made from semiconductors that convert sunlight to electrical power directly, these cells are categorized into three groups depend on the material used in the

Monocrystalline photovoltaic panels: what they are and their

Dec 11, 2024 · Their distinguishing feature is their cells, which are made of monocrystalline silicon, a pure and homogeneous material that guarantees superior energy performance

Crystalline Silicon Photovoltaics Research

3 days ago · The U.S. Department of Energy (DOE) Solar Energy Technologies Office (SETO) supports crystalline silicon photovoltaic (PV) research and

Explanation of the principle of monocrystalline silicon

Photovoltaic (PV) installations have experienced significant growth in the past 20 years. During this period, the solar industry has witnessed technological advances, cost reductions, and

Monocrystalline vs. Polycrystalline Solar Cells

Dec 17, 2024 · As demand for clean energy resources has grown, solar energy has emerged as a cornerstone innovation in renewable electricity generation.

Solar Photovoltaic Cell Basics

3 days ago · There are a variety of different semiconductor materials used in solar photovoltaic cells. Learn more about the most commonly-used materials.

Monocrystalline solar panels: a comprehensive guide

Aug 30, 2024 · Monocrystalline panels are composed of monocrystalline cells obtained by cutting slices of silicon ingots through the Czochralski system. This is a process in which a crystal

Properties of polycrystalline silicon cell

Oct 26, 2018 · Polycrystalline silicon is a material composed of multiple misaligned silicon crystals. It serves as an intermediate between amorphous

Types of solar cells: description of photovoltaic

Feb 12, 2016 · Monocrystalline silicon solar cells (M-Si) are made of a single silicon crystal with a uniform structure that is highly efficient. Polycrystalline

Status and perspectives of crystalline silicon photovoltaics in

Mar 7, 2022 · Crystalline silicon solar cells are today''s main photovoltaic technology, enabling the production of electricity with minimal carbon emissions and at an unprecedented low cost. This

Monocrystalline Solar Panels: How They Work,

Sep 16, 2023 · Monocrystalline solar panels utilize monocrystalline silicon cells to transform sunlight into usable electrical energy. These cells are made from

What Is a Monocrystalline Solar Panel?

Aug 4, 2024 · Monocrystalline photovoltaic (PV) cells are made from a single crystal of highly pure silicon, generally crystalline silicon (c-Si).

6 Major Types of Photovoltaic Cells in Solar Panels

Aug 19, 2021 · Therefore, they are currently a more expensive option Hybrid photovoltaic solar cell Hybrid silicon Typical efficiency 18%. The most expensive but also most efficient type of

What Are Solar Panels Made Of and How Are

Feb 27, 2024 · Silicon is one of the most important materials used in solar panels, making up the semiconductors that create electricity from solar energy.

What is Monocrystalline Silicon?

Nov 17, 2023 · What is Monocrystalline Silicon: It''s a single-crystal silicon with high purity, characterized by a uniform & crystal lattice structure.

What Are Solar Panels Made Of and How Are

Feb 27, 2024 · Solar panels are made of monocrystalline or polycrystalline silicon solar cells soldered together and sealed under an anti-reflective glass cover.

Components of a Solar Panel: Complete Technical Guide

1 day ago · Solar panel adoption has reached unprecedented levels in 2025, with over 3.2 million residential installations across the United States alone. As photovoltaic technology continues

What is Monocrystalline Solar Panel: A

Mar 23, 2024 · A solar panel is technically known as PV or photovoltaic panel because each comprises small, interconnected PV cells. By the way, do you

6 FAQs about [Which part of the photovoltaic panel is the monocrystalline silicon]

What is a monocrystalline solar panel?

They are made from monocrystalline solar cells formed from a single piece of silicon. This gives an easy path for electricity to pass through them. The cylindrical silicon ingot generated from high-quality single-crystal silicon is the reason behind its name. Monocrystalline panels have a larger surface area due to the pyramid cell pattern.

How are monocrystalline solar panels made?

Monocrystalline solar panels are produced from one large silicon block in silicon wafer formats. The manufacturing process involves cutting individual wafers of silicon that can be affixed to a solar panel. Monocrystalline silicon cells are more efficient than polycrystalline or amorphous solar cells.

What is the difference between a monocrystalline and a polycrystalline solar cell?

Monocrystalline silicon solar cells (M-Si) are made of a single silicon crystal with a uniform structure that is highly efficient. Polycrystalline silicon solar cells (P-Si) are made of many silicon crystals and have lower performance. Thin-film cells are obtained by depositing several layers of PV material on a base.

What is a monocrystalline photovoltaic (PV) cell?

Monocrystalline photovoltaic (PV) cells are made from a single crystal of highly pure silicon, generally crystalline silicon (c-Si). Monocrystalline cells were first developed in the 1950s as first-generation solar cells. The process for making monocrystalline is called the Czochralski process and dates back to 1916.

What percentage of solar panels are monocrystalline?

Monocrystalline solar cells now account for 98% of solar cell production, according to a 2024 report from the International Energy Agency. This compares starkly with 2015, when just 35% of solar panel shipments were monocrystalline, according to the National Renewable Energy Laboratory.

What is the efficiency of a monocrystalline photovoltaic (PV) panel?

With an efficiency rate of up to 25%, monocrystalline panels reach higher efficiency levels than both polycrystalline (13-16%) and thin-film (7-18%) panels. Monocrystalline photovoltaic (PV) cells are made from a single crystal of highly pure silicon, generally crystalline silicon (c-Si).

Industry Information

- Andorra Small Solar Air Conditioner Price

- Portable power to connect the home

- Sana s new supercapacitor car price

- Energy storage power station demonstration

- What are the container power generation equipment in Ecuador

- Disadvantages of photovoltaic cascade energy storage power stations

- Türkiye 210 degree liquid cooling energy storage cabinet solution

- 10 monitors how many watts of solar energy

- Level 5 communication base station inverter

- 1000 wh power station factory in Costa-Rica

- Belgian zinc-iron liquid flow energy storage battery

- Smart Energy Storage Battery Cabinet Manufacturer Ranking

- Timor-Leste hybrid energy 5g700m base station hybrid power supply

- How big of an inverter should a 1000ah lithium battery be matched with

- Construction work of wind and solar complementary communication base station at night

- Ankara Energy Storage Container Production

- Lithium battery station cabinet double shoulder

- Banji Smart Photovoltaic Water Pump Inverter

- HA16 Battery Cabinet

- Niue Photovoltaic Power Inverter

- How much does photovoltaic glass weigh

- North Macedonia inverter wholesaler

- South Sudan Power Grid Energy Storage Enterprise

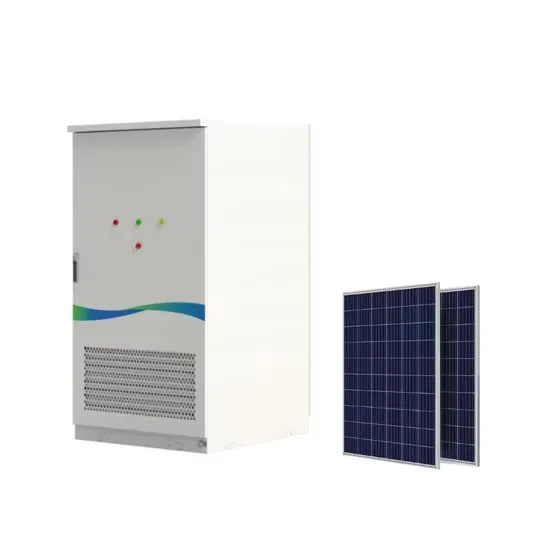

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.