Automation cabinets

Hardware planning and construction, for numerous applications such as: Process control technology systems: Control technology cabinets (PLC, RIO, servers etc.) Production

Battery cabinet system | HuiJue Group E-Site

Battery Cabinet LED Indicators When technicians approach a battery cabinet, their eyes instinctively scan the LED indicators. But how many operators truly understand the operational

Battery Cabinet Automation Controls | HuiJue Group E-Site

As global energy storage capacity surges past 1.5 TWh, battery cabinet automation controls emerge as the unsung heroes. But why do 38% of industrial facilities still report thermal

BATTERY PRODUCTION OF THE FUTURE

Jan 2, 2025 · ELECTRODE PRODUCTION Regardless of the type of cell or battery produced, we understand the entire production process: Whether it be dosing, mixing, drying or compacting.

Control cabinets

Mar 4, 2024 · Their role is crucial in ensuring the safe and efficient management of many processes. Failures of various kinds in power distribution systems,

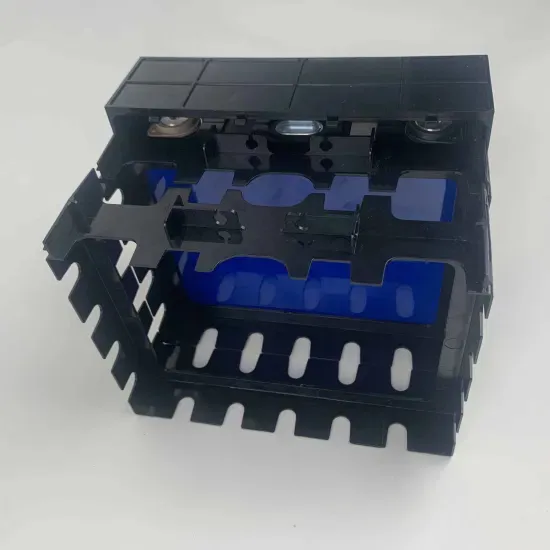

(PDF) BATTERY MODULE AND PACK ASSEMBLY

Feb 6, 2019 · Abstract Our second brochure on the subject "Assembly process of a battery module and battery pack" deals with both battery module assembly

Automatic assembly of batteries in energy storage cabinets

Each Battery cabinet contains two battery strings,each battery string contains total 26 batterymodules connected in series. Each battery cabinet contains two HVAC system,and one

Automation solutions for battery production

Oct 30, 2024 · Automation solutions for battery production. High speed, high throughput, maximum reliability, repetition accuracy and low costs: these are the features that are required

Optimize Battery Assembly Line with Design and

4 days ago · In this blog, we''ll explore how smart design and automation can help you break through the bottleneck. You''ll discover how effective mechanical design and controls

Battery Manufacturing & Testing

Discover automated battery manufacturing and testing solutions for modules and packs, ensuring efficiency, scalability, and high-quality production.

The Cabinet Manufacturing Process Read the featured article News Furniture The Cabinet Manufacturing Process. Cabinets are a crucial part of any kitchen construction project and

BIW projects and automation solutions

Aug 19, 2025 · Scalability – Choose a partner capable of handling large-scale projects. One-Stop Solution for BIW & Automation Needs Pune''s leading

Battery production of the future | Bosch Rexroth

As a provider of automation solutions, Bosch Rexroth supports the entire value stream: From electrode and cell production to battery module and pack

Energy storage cabinet assembly automation design

At JR Automation, our experience doesn''''t stop at battery module and pack assembly or EV powertrain assembly. Our team can help you design automation solutions for the

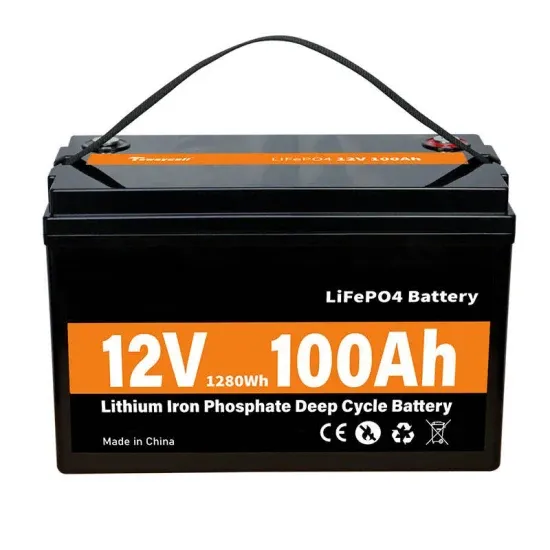

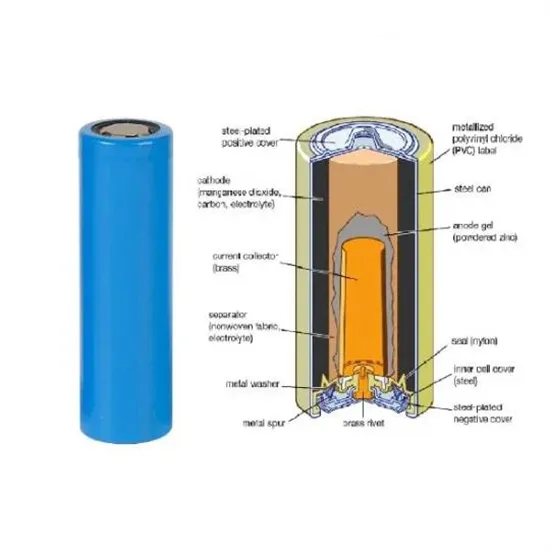

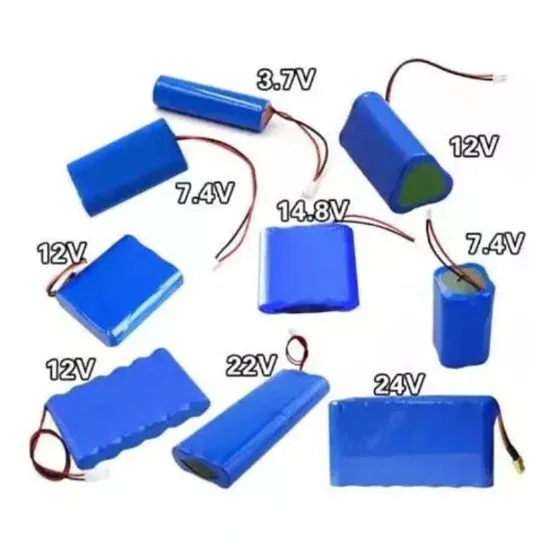

Lithium-Ion Battery Pack Manufacturing Process

Jun 4, 2025 · This final stage in the lithium-ion battery manufacturing process integrates individual cells into fully functional battery modules, complete with

Automated battery manufacturing

Just push the button Cutting-edge research and prototype factories are helping to advance the automation of EV component manufacturing, writes Nick Flaherty

Advanced New Energy Lithium Battery PACK

Lithium battery assembly, Automated production line, Battery pack manufacturing, New energy battery, Industry 4.0, Smart manufacturing, High-precision

Automation of Operations in Assembly of Battery Modules in

Jan 1, 2024 · By employing robots and other automation technologies, the assembly process can be streamlined, reducing bottlenecks, and minimizing the risk of error and electrocution. This

C & D Technologies | Stationary Battery Cabinets

C&D battery cabinets and enclosures Battery cabinet solutions for pure lead agm batteries From the industry leader in data center backup batteries, C&D now

Mastering the Battery Pack Assembly Process: A

Jan 23, 2025 · Introduction The battery pack assembly process is a cornerstone of modern manufacturing, essential for producing high-performance battery

Battery Cell and Pack Production for Electric

Mar 12, 2025 · HANNOVER: Battery Cell and Pack Production for Electric Mobility At the upcoming HANNOVER MESSE, 11 companies will jointly present the

Transforming Battery Manufacturing:

Jan 7, 2025 · The global battery manufacturing industry is in the midst of an evolution driven by advanced automation, AI and the rapid rise in EV and

Battery assembly solution

Aug 19, 2025 · Watch the JOT Battery Assembly Solution in action. JOT Automation''s industry-leading battery assembly solution is a fully complete,

Energy storage cabinet assembly automation design

What is Bess ion & energy and assets monitoring? ion - and energy and assets monitoring - for a utility-scale battery energy storage systemBESS). It is intended to be used together with

What Is A PLC Control Cabinet? A

Nov 26, 2024 · With their versatility and reliability, PLC control cabinets are a cornerstone of modern industrial automation. Introduction to PLC Control

How AZE Systems Manufactures BESS Battery Energy Storage Cabinets

Feb 21, 2025 · Manufacturing a Battery Energy Storage System (BESS) cabinet is a complex process that involves designing, engineering, and assembling a robust and reliable system to

Battery Automation | Siemens Software

May 9, 2025 · Learn how to use digitization to promote consistency and speed in final product development by facilitating the sourcing, reuse, and

Automation of Operations in Assembly of Battery Modules in

Jan 1, 2024 · The assembly of battery modules in a battery electric vehicle (BEV) plant involves several critical operations, including tightening screws to make connections between various

European research project to create battery development

Apr 28, 2025 · The research project will take a holistic approach to the entire battery development process, from material discovery to the deployment of next-generation batteries, and has

SUNSYS HES L

Apr 29, 2024 · SUNSYS HES L integrates advanced power conversion and LFP battery technologies to create a winning formula. The B-Cab ( battery storage cabinet) uses liquid

EV Battery Production. Optimized.

Aug 1, 2023 · If you''re an EV battery producer, your success depends on strategically upscaling battery gigafactory operations and maintaining extraordinary throughput, quality and yield. The

Battery assembly solution

Aug 19, 2025 · JOT Automation''s industry-leading battery assembly solution is a fully complete, turnkey solution for battery assembly that is also EV battery

EV Battery Production. Optimized.

Aug 1, 2023 · To improve operations, the Rockwell Automation MES for battery But that''s not all. The integrated solution also expands to module and production seamlessly manages and

Automation in battery production

Dec 18, 2023 · KUKA offers automation solutions for the entire value chain of battery production. Sustainable process technologies play an important role

6 FAQs about [Battery cabinet automation project process]

What is the Jot battery assembly solution?

Watch the JOT Battery Assembly Solution in action. JOT Automation’s industry-leading battery assembly solution is a fully complete, turnkey solution for battery assembly that is also EV battery compatible. Highlights include automated unpacking of incoming material, testing, welding applications and final-product testing.

What is a battery assembly solution?

The comprehensive Battery Assembly solution can be equipped with an array of options, including unpacking, waste disposal, electrical testing, enclosure and casing assembly, PCB assembly, laser welding and final-product testing. Plus the solution's compartmentalized design ensures high-grade fire safety to keep its processes and surroundings safe.

Why is battery assembly important?

In the competitive world of electric vehicles and energy storage, efficient and precise battery assembly is crucial for meeting high performance and safety standards. At JOT Automation, we provide cutting-edge solutions for battery module assembly and battery pack assembly, ensuring seamless integration and optimized production.

Why do we need automation in battery production?

Demand for lithium-ion batteries is booming. From smartphones and tablets to e-cars: nothing runs without batteries. Accordingly, the required quantities in battery production are increasing rapidly. The solution lies in automation. This is because the manufacture of batteries is technically demanding and requires high safety standards.

What is battery-cell production?

Battery-cell production includes a wide applications, beginning with the validation, management of raw materials to mixing, discrete assembly and more. Put simply, producers face hybrid manufacturing at Not all MES solutions can address this range with typical solutions tailored to either process control.

Why are battery machine builders turning to automation?

With the demand for battery solutions driven by global green energy trends outstripping machine supply, strong competition is necessitating smarter approaches to battery machine design. Battery machine builders are turning to automation to stay ahead of the curve.

Industry Information

- Road led solar street light design

- Installing solar photovoltaic panels in Australia

- Which solar energy outdoor in Africa is better

- Albania Sun Room Photovoltaic Panel Manufacturer

- How many watts of solar energy does a 70w LED require

- 40 kW solar power generation in Muscat

- How much is the subsidy for the photovoltaic curtain wall in Castries

- Bogota Civilian Inverter Manufacturer

- Hot sale 100kw solar inverter for sale Price

- 100ah power station in China in Abu-Dhabi

- Cyprus Heavy Industry Energy Storage Cabinet Customization

- Transformer breaker for sale in Canberra

- Huawei Albania sine wave inverter direct delivery

- Are there any lead-acid battery service providers for communication base stations in Gaborone

- How to scan for battery replacement at the site

- Southern Europe photovoltaic panel m-type trough manufacturer

- One hundred watt solar photovoltaic panel

- What is the user side of energy storage power station

- Rooftop photovoltaic wind energy storage

- Factory price 110 amp breaker in Netherlands

- Liquid cooling energy storage cabinet 125kw230kwh

- Mozambique lithium battery cylindrical cell

- Uninterruptible Power Supply in Kazakhstan

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

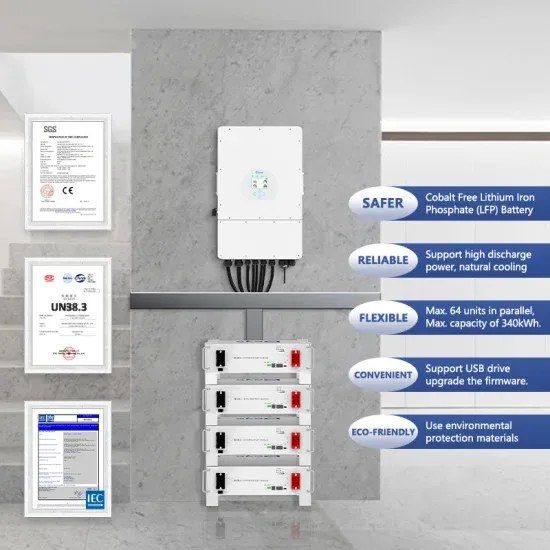

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.