(PDF) BATTERY MODULE AND PACK ASSEMBLY

Feb 6, 2019 · Our second brochure on the subject "Assembly process of a battery module and battery pack" deals with both battery module assembly and

Mastering the Battery Pack Assembly Process: A

Jan 23, 2025 · What is the Battery Pack Assembly Process? The battery pack assembly process is a meticulously planned sequence of steps that

Vingroup starts construction on EV Battery

December 12, 2021 – The People''s Committee of Ha Tinh Province and Vingroup officially began construction of the VinES Battery Manufacturing Factory in the

Battery Module: Manufacturing, Assembly and Test Process

Dec 28, 2022 · In the Previous article, we saw the first three parts of the Battery Pack Manufacturing process: Electrode Manufacturing, Cell Assembly, Cell Finishing. Article Link. In

MAN BatteryPacks now also for industrial

Mobile and stationary applications in agricultural machinery, construction machinery, railway, shipping and energy at a glanceThe Group''s own all

CATL continues to ramp up battery production

Feb 18, 2025 · Chinese market leader CATL has already opened its first battery factory in Europe in 2023. The company is currently working on further scaling

INSTRUCTION MANUAL: BATTERY PACK DESIGN, BUILD

Apr 29, 2021 · install partitions between BMS and cells check if the pack is designed to be able to avoid thermal runaway analyze the battery pack''s thermal distribution and its effect on the

No, America''s battery plant boom isn''t going

Nov 1, 2024 · The United States is in the midst of the biggest boom in clean energy manufacturing investments in history.

Amara Raja inaugurates Battery Pack Assembly

Aug 10, 2024 · Amara Raja inaugurates Battery Pack Assembly Plant and lays foundation stone for Customer Qualification Plant at its Giga Corridor Amara

The Battery Cell Factory of the Future | BCG

Jan 30, 2025 · The Battery Cell Factory of the Future Offers Solutions The battery cell factory of the future addresses the challenges of cost optimization through

Battery assembly systems

Technological change in the automotive drivetrain is already playing a significant role today. This will expand further in the coming years and become

Battery Plant Design Do''s and Don''ts

Sep 15, 2023 · Battery factories require a new way of thinking about plant design and construction. Manufacturing engineers must pay careful attention to

EV Lithium Battery Production 101 | Bonnen

Sep 3, 2024 · Explore EV battery production with Bonnen Battery! We''re the manufacturer in making top-notch lithium batteries for electric cars.

Inside Nexcharge''s fully automated battery pack

May 18, 2022 · Nexcharge, a joint venture between Exide Industries Limited (Exide) and Leclanché SA, recently announced the inauguration of its state-of

Simulation-driven EV Battery Pack Design And

May 7, 2020 · Equally importantly, simulation software such as Siemens Plant Simulation can empower battery pack manufacturers to impact the bottom line

Tracking the EV Battery Factory Boom in U.S.

The landscape of electric vehicle (EV) battery production in North America has undergone a remarkable transformation in recent years. What began as a

Sustainable manufacturing practices for EV battery packs:

Jun 1, 2025 · This paper also prescribes a full life cycle model of suing sustainable practices while obtaining, manufacturing, using and recycling EV battery packs with advanced secondary life

Reliance to begin battery gigafactory operations

Aug 30, 2024 · RIL''s battery giga factory will manufacture battery chemicals, cells and packs. Reliance to begin battery gigafactory operations in 2026. 30 GWh

Lifetime and Aging Degradation Prognostics for Lithium-ion Battery

Jan 9, 2022 · Experimental results show that the lifetime prediction errors are less than 25 cycles for the battery pack, even with only 50 cycles for model fine-tuning, which can save about 90%

No, America''s battery plant boom isn''t going

Nov 1, 2024 · Workers install battery packs in a BMW X5 in South Carolina. A new battery plant under construction nearby will supply BMW factories.

Ten new battery plants to double US capacity to

Feb 25, 2025 · Ten new battery plants to double US capacity to 421.5 GWh for EV adoption boost If import fees rise on raw materials from China, tariff

How to Build a Lithium Ion Battery Pack: Expert Guide for

Aug 1, 2025 · What are the key components needed to build a lithium-ion battery pack? The key components include lithium-ion cells (cylindrical, prismatic, or pouch), a battery management

Design and validate battery manufacturing

May 28, 2025 · Quickly create and simulate early factory floor layouts for battery cell production. Identify bottlenecks and layout inefficiencies before any

PRODUCTION PROCESS OF BATTERY MODULES AND

Feb 7, 2024 · , this brochure presents the process chain for the production of battery modules and battery packs. The individual cells are connected in series or parallel in a module. Several

ETN News | Energy Storage News | Renewable

3 days ago · ETN news is the leading magazine which covers latest energy storage news, renewable energy news, latest hydrogen news and much more.

Lithium-ion Battery Pack Manufacturing Process & Design

Jul 28, 2023 · In this article, we will explore the world of battery packs, including how engineers evaluate and design custom solutions, the step-by-step manufacturing process, critical quality

Battery Pack Development Timeline

Our battery pack development timeline covers the scope of a battery project and the time between developing prototypes and finally end product production.

Lithium-ion Battery Manufacturing in India –

May 12, 2023 · Lithium-ion Battery Pack Assembly for EV Applications Many companies in India supply lithium-ion batteries for non-EV applications like

Tracking the EV battery factory construction

Feb 7, 2025 · Battery factories are popping up across North America. Here''s where they are and how the Inflation Reduction Act influenced the boom.

6 FAQs about [Battery pack plant construction cycle]

What are the three parts of battery pack manufacturing process?

Battery Module: Manufacturing, Assembly and Test Process Flow. In the Previous article, we saw the first three parts of the Battery Pack Manufacturing process: Electrode Manufacturing, Cell Assembly, Cell Finishing. Article Link In this article, we will look at the Module Production part.

What is the battery pack manufacturing process?

The battery pack manufacturing process involves cell selection, module assembly, wiring, thermal management, and safety integration. Each step ensures efficiency, reliability, and durability. Understanding this process helps manufacturers optimize production, clients get tailored solutions, and consumers receive safer, longer-lasting batteries.

What is the process chain for the production of battery modules?

, this brochure presents the process chain for the production of battery modules and battery packs. ● The individual cells are connected in series or parallel in a module. Several modules and other electrical, mechanical and thermal components are assembled into a pack. Battery value chain Overview of the production sequence from cell to system

What are the final stages of the battery pack manufacturing process?

The final stages of the battery pack manufacturing process involve careful handling, transportation, and implementation to ensure products reach their destination safely and function as intended. Battery packs require specialized packaging to prevent damage: Each shipment contains essential information:

What is the production process of lithium-ion battery cells?

"Production process of lithium-ion battery cells" , this brochure presents the process chain for the production of battery modules and battery packs. ● The individual cells are connected in series or parallel in a module. Several modules and other electrical, mechanical and thermal components are assembled into a pack. Battery value chain

What is battery pack assembly process?

Battery Pack Assembly Process Component Preparation: High-quality battery cells, BMS, wiring, and casings are inspected and prepared for assembly. Cell Assembly: Battery cells are arranged in series or parallel configurations to achieve the required voltage and capacity.

Industry Information

- Containerized photovoltaic mobile integrated machine

- Maintenance of photovoltaic power generation for grid-connected inverter of communication base station

- Photovoltaic glass factory for export in New York USA

- Outdoor photovoltaic battery battery cabinet 36KW

- How much does the UPS uninterruptible power supply cost for the Berlin power distribution room

- 220mA inverter

- Muscat lithium battery PACK

- Male energy storage temperature control system equipment

- 8000w60v smart inverter

- Advantages and disadvantages of discharge energy storage gel batteries

- New Zealand energy storage project approved

- Energy Storage Container Decomposition

- High quality wholesale switchgear breaker company

- Freetown cylindrical lithium battery manufacturer

- Cheap wholesale battery and storage for sale

- Haiti Outdoor Power Plant

- Rooftop solar panels

- Outdoor portable mobile charging source

- 120A Battery Inverter

- Differences between energy storage batteries and energy storage power stations

- Guinea special photovoltaic folding container wholesale

- Aluminum cables can be used for wind and solar hybrid communication base stations

- Cape Verde inverter price

Commercial & Industrial Solar Storage Market Growth

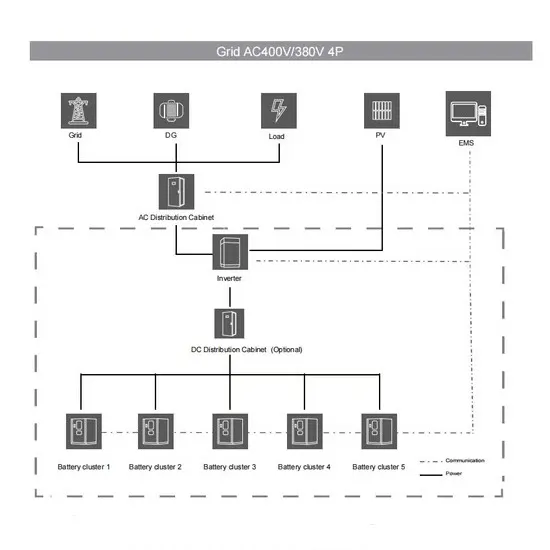

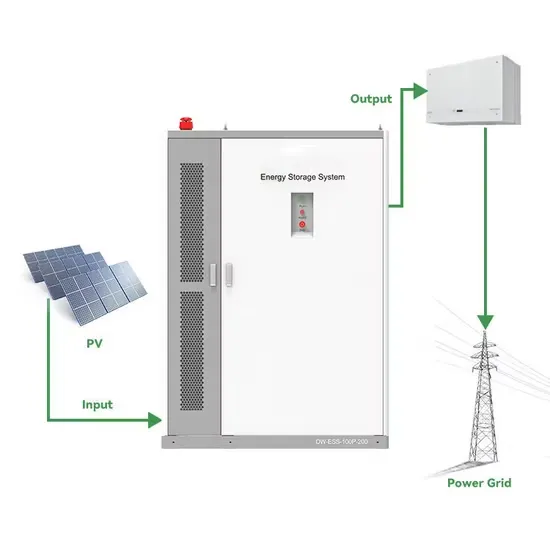

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

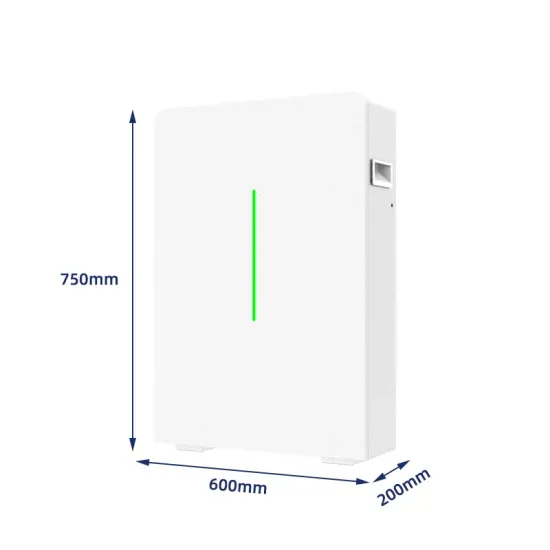

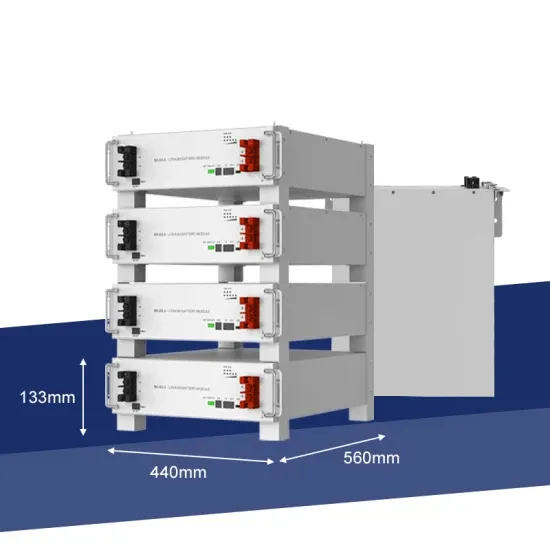

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.