Automated assembly of Li-ion vehicle batteries: A feasibility study

Jan 1, 2020 · Electric Vehicles (EVs) with rechargeable Lithium-Ion batteries (Li-ion) are at the forefront of the global trend for lower-emission transportation and decarbonisation. Capable

32v lithium battery assembly 60v battery pack

The Aegis Battery 60V 50Ah Li-ion Battery is a state of the art rechargeable battery pack made with 18650 cells designed for 60V devices. It is perfect for e-scooters, e-bikes, solar

The Ultimate Guide For Lithium-Ion Battery

This in-depth guide explores lithium-ion battery packs from the inside out. Learn about the key components like cells, BMS, thermal management, and enclosure.

Battery Cell, Module or Pack. What''s the

Jun 30, 2022 · The manufacturing of battery cells compared to battery packs or modules are two very different industrial processes. Battery cell production is

How Are Lithium Batteries Assembled?

May 2, 2025 · Lithium batteries are a critical component of various devices, from smartphones and laptops to electric vehicles and energy storage systems. Understanding the assembly

Battery Pack Assembly : 5 Steps

Battery Pack Assembly: The goal of this project is to create a battery pack from purchased power cells. Is important to understand how cells can be connected

Kinstar LiFePO4 18650 32V 6000mAh Battery Pack

Lithium-ion, Lithium-ion Polymer or LiFePO4 batteries: Innovative Power Solutions by Kinstar makes the battery pack more reliable, durable and safer.

Battery Module: Manufacturing, Assembly and Test Process

Dec 28, 2022 · In the Previous article, we saw the first three parts of the Battery Pack Manufacturing process: Electrode Manufacturing, Cell Assembly, Cell Finishing. Article Link. In

How Are Lithium Battery Packs Assembled?

Aug 18, 2025 · By following the key steps involved in lithium battery pack assembly, including cell selection and testing, cell arrangement and connection, BMS integration, and final assembly

Ultimate Guide to Battery Voltage Chart

Dec 29, 2023 · Voltage Curves for Different Types of Batteries Lithium Iron Phosphate Battery Voltage Curve Lithium iron phosphate (LiFePO4) battery

Designing a Lithium-Ion Battery Pack: A Comprehensive Guide

Feb 15, 2025 · Before diving into the design process, it''s crucial to understand the fundamental components of a lithium-ion battery pack: Cells: The basic building blocks of a battery pack.

(PDF) BATTERY MODULE AND PACK ASSEMBLY

Feb 6, 2019 · PDF | Our second brochure on the subject "Assembly process of a battery module and battery pack" deals with both battery module assembly

Battery Pack Assembly: From Cells to Power Packs

Once the battery pack is assembled, a crucial step remains – the application of the Battery Management System (BMS). The BMS plays a pivotal role in

How are Lithium-ion Battery Packs Manufactured?

Lithium-ion battery packs are manufactured through a meticulous process that includes two key parts: the Battery Management System (BMS) and the battery pack assembly. The BMS is

A review of state-of-health estimation for lithium-ion battery packs

May 15, 2025 · With the rapid advancement of lithium-ion battery technology, the estimation of the state of health (SOH) of lithium-ion battery packs plays a crucial role in enhancing the safety

LiPo 17000mAh 10S 37v Battery Pack

The MaxAmps 17000mAh 10s 37v LiPo battery is built for drones, UAV, VTOL, aerospace, and robotics applications. Assembled in the USA. Includes

Battery pack design and assembly processes

Mar 26, 2024 · By understanding the key terms and definitions, model or formula, summary of the development background, case study and examples of the applications of battery pack design

How to Build a Lithium Ion Battery Pack: Expert Guide for

Aug 1, 2025 · What are the key components needed to build a lithium-ion battery pack? The key components include lithium-ion cells (cylindrical, prismatic, or pouch), a battery management

Mastering the Battery Pack Assembly Process: A

Jan 23, 2025 · What is the Battery Pack Assembly Process? The battery pack assembly process is a meticulously planned sequence of steps that

32 v lithium ion battery Brand

Jan 27, 2024 · 2、The 32v Lithium Ion battery is a type of rechargeable battery commonly used in consumer electronics and electric vehicles due to its high energy density and long cycle life.

32V 20Ah Lithium Iron Phosphate Battery Pack Low

We are dedicated to the research, design, manufacture, and distribution of primary batteries, lithium-ion batteries, polymer batteries, and primary lithium batteries. Our breakthroughs in

Battery Pack Manufacturing Process

Mar 15, 2025 · In this post, you''ll learn the entire battery pack manufacturing process. We''ll cover cell selection, module assembly, safety testing, and

How to Dissemble Lithium Battery Packs and

Nov 3, 2022 · Learning how to dissemble lithium-ion battery packs is a great way to score some lithium batteries and cells for cheap.

32V lithium battery pack production process

Lithium Battery PACK Production Line Processes and Equipment The Lithium Battery PACK production line encompasses processes like cell selection, module assembly, integration,

Questions about E-Bike battery upgrade | Endless Sphere

Aug 15, 2016 · Hi all, I got some questions about E-Bikes and I hope I get some answers here. My E-Bike is 250 Watts with Lead Acid 48V20AH battery (probably it has 4 x 12V20AH batteries

32V Battery

Understanding the 32V Battery The 32V battery is a versatile power solution that offers significant advantages for numerous applications, particularly in sectors demanding robust energy

PRODUCTION PROCESS OF BATTERY MODULES AND

Feb 7, 2024 · , this brochure presents the process chain for the production of battery modules and battery packs. The individual cells are connected in series or parallel in a module. Several

32V Battery Pack Lithium

Upgrade to our 32V battery pack lithium and experience the difference that premium quality can make. With its exceptional performance, long-lasting capacity, and safety features, our 32V

Battery Cells, Modules, and Packs: Key Differences Explained

Apr 18, 2025 · Understanding Battery Cells, Modules, and Packs Introduction to Battery Structure In modern energy storage systems, batteries are structured into three key components: cells,

How Are Lithium Battery Packs Assembled?

Aug 18, 2025 · How Are Lithium Battery Packs Assembled? Lithium battery packs are essential components in various applications, from electric vehicles to renewable energy storage

Lithium-ion Battery Pack Manufacturing Process & Design

Jul 28, 2023 · CMB''s battery pack designer gives priority to the following three most common battery cells for the battery pack design: INR (Ternary Lithium), LFP (Lithium Iron Phosphate

32 V Power Tool Batteries for sale

Get the best deals on 32 V Power Tool Batteries when you shop the largest online selection at eBay . Free shipping on many items | Browse your favorite brands | affordable prices.

6 FAQs about [60 lithium batteries assembled into a 32v battery pack]

What are the three parts of battery pack manufacturing process?

Battery Module: Manufacturing, Assembly and Test Process Flow. In the Previous article, we saw the first three parts of the Battery Pack Manufacturing process: Electrode Manufacturing, Cell Assembly, Cell Finishing. Article Link In this article, we will look at the Module Production part.

What is the production process of lithium-ion battery cells?

"Production process of lithium-ion battery cells" , this brochure presents the process chain for the production of battery modules and battery packs. ● The individual cells are connected in series or parallel in a module. Several modules and other electrical, mechanical and thermal components are assembled into a pack. Battery value chain

What is the battery pack manufacturing process?

The battery pack manufacturing process involves cell selection, module assembly, wiring, thermal management, and safety integration. Each step ensures efficiency, reliability, and durability. Understanding this process helps manufacturers optimize production, clients get tailored solutions, and consumers receive safer, longer-lasting batteries.

What is battery pack assembly process?

Battery Pack Assembly Process Component Preparation: High-quality battery cells, BMS, wiring, and casings are inspected and prepared for assembly. Cell Assembly: Battery cells are arranged in series or parallel configurations to achieve the required voltage and capacity.

What is a lithium ion battery pack?

A battery pack consists of multiple cells connected in series or parallel. How to make lithium-ion batteries? It’s always been an interesting topic. The production of lithium-ion batteries is a complex process, totaling Three steps. The cell sorting stage is a critical step in ensuring the consistent performance of lithium-ion batteries.

What is battery module assembly process?

The battery module assembly process is a crucial step in the battery pack manufacturing process, where individual battery cells are grouped into modules. This stage enhances efficiency, safety, and performance by integrating electrical connections, thermal management systems, and safety features.

Industry Information

- Single phase circuit breaker in Costa-Rica

- Barbados Photovoltaic Glass Greenhouse

- Telecom Modular Container Energy Storage

- Laos outdoor power supply price

- Solar Voltage System

- Structure of the inner part of a square lithium battery

- Civil construction cost of 1gw energy storage

- Lithium battery energy storage system in Casablanca Morocco

- Independent energy storage power station participates in frequency regulation

- Outdoor boost inverter

- EU photovoltaic household energy storage

- Thailand installs photovoltaic energy storage project

- Austria builds energy storage power station

- What is the function of the energy storage cabinet container

- Palestinian household energy storage battery components

- Juba Energy Storage Container Power Station Service

- The current demand for lead-carbon battery energy storage

- Communication base station energy storage relocation project

- Consumer lithium battery pack manufacturers

- Which brand of outdoor power supply should I buy

- Energy storage cabinet thermal insulation protection device base station

- How many watts of rooftop solar energy

- Outdoor power supply capable of outputting 12v24v36v

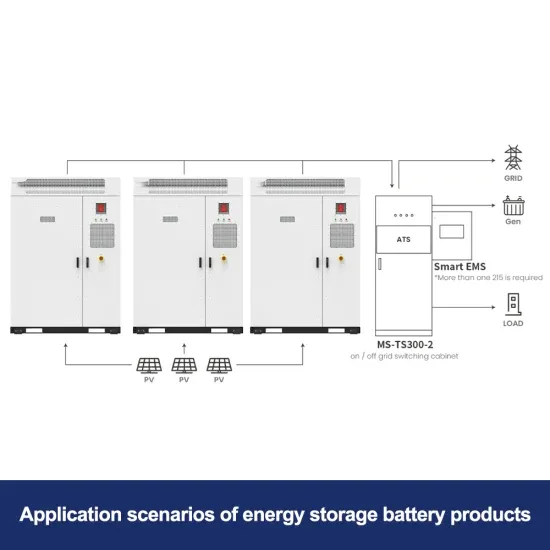

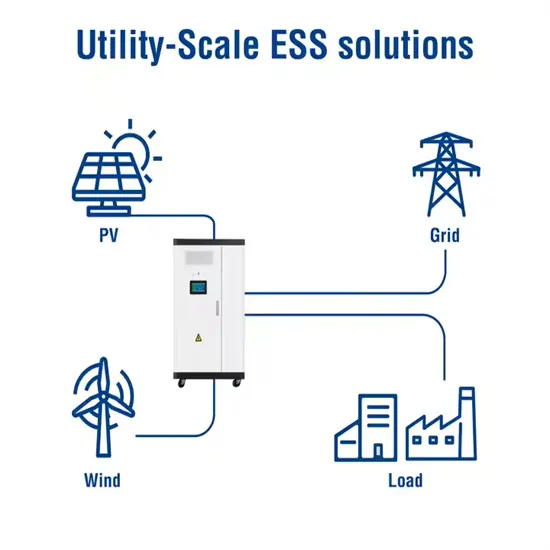

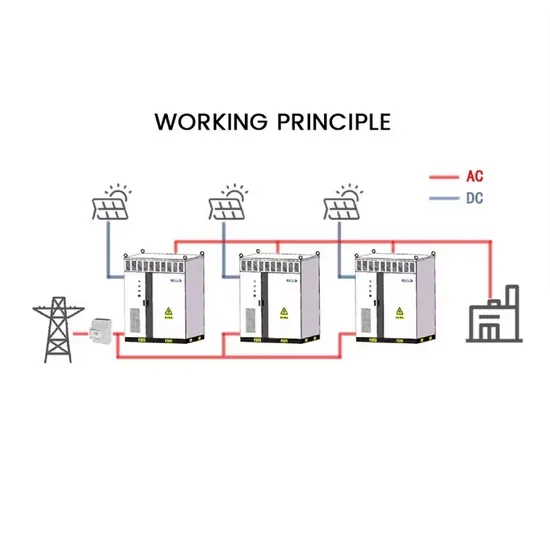

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.