Common Architectures and Devices for Current

Jul 27, 2023 · When compared to the much more common voltage-source inverter (VSI), the current-source inverter (CSI) is rarely used for variable

AC Motor Inverters: How They Work, Principles, And

May 19, 2025 · AC motor inverters are devices that convert direct current (DC) into alternating current (AC) to control the speed and torque of electric motors. They are essential for

Three-phase inverter reference design for 200-480VAC

May 11, 2022 · In-phase shunt resistor based motor current sensing is done using AMC1300B isolated amplifier and DC link voltage, IGBT module temperature sensing using the AMC1311

Power Inverters: What Are They & How Do They

Dec 17, 2019 · Key learnings: Inverter Definition: An inverter is defined as a power electronics device that converts DC voltage into AC voltage, crucial for

Inverter Voltage Calculator, Formula, Inverter Voltage

3 days ago · It describes the output voltage of an inverter, which converts direct current (DC) from sources like batteries or solar panels into alternating current (AC). The output voltage of an

What Is an Inverter in an Electric Vehicle?

Aug 9, 2023 · An inverter is a device that converts direct current (DC), which is supplied from a battery, into alternating current (AC). A motor in an electric vehicle runs on this alternating

How an Inverter Drive Works and Controls the Speed of an AC Induction Motor

An Inverter Drive (VFD) works by taking AC mains (single or three phase) and first rectifying it into DC, the DC is usually smoothed with Capacitors and often a DC choke before it is connected

CSM_Inverter_TG_E_1_1

Mar 27, 2016 · An inverter uses this feature to freely control the speed and torque of a motor. This type of control, in which the frequency and voltage are freely set, is called pulse width

DC-to-AC Converters (Inverters): Design,

May 20, 2023 · The electrical circuits that transform Direct current (DC) input into Alternating current (AC) output are known as DC-to-AC Converters or

Inverter Voltage Calculator

Mar 27, 2024 · The DC bus voltage is crucial in an inverter''s operation as it serves as the primary source of power that the inverter converts into AC voltage. The level of DC bus voltage directly

Single Phase Inverter

Jul 23, 2025 · Single Phase Inverter A single-phase inverter is a type of inverter that converts DC source voltage into single-phase AC output voltage at a

DC Current Control for a Single-Stage Current Source Inverter in Motor

Aug 3, 2020 · The current source inverter (CSI) is a power electronics topology that allows for the realization of variable speed drives (VSD). Compared to the most common voltage source

inverters

This type of control, in which the frequency and voltage are freely set, is called pulse width modulation, or PWM. The inverter first converts the input AC

Electric Motor Inverter Explained

Jun 23, 2025 · How an electric motor inverter works, with expert teardown insights and in-depth analysis from the team at Munro.

Three Phase Inverter : Circuit, Working, Types

May 31, 2023 · An inverter is an electrical device mainly used to change current from DC to AC form. It is also known as a variable frequency drive (VFD) or

3-phase PMSM Motor Control Power Inverter Module

Feb 1, 2024 · FreeMASTER software monitor FreeMASTER embedded Motor Control Application Tuning (MCAT) tool (motor parameters, current loop, speed loop) (see section References).

How Inverter Drives Control AC Induction Motors

Mar 17, 2025 · Inverter Drives, often referred to as Variable Frequency Drives (VFDs), are pivotal in modern industrial automation. These devices are designed to control the speed and torque

Inverter Voltage Calculator

Mar 27, 2024 · Enter the DC bus voltage (volts) and the difference in modulation indices into the calculator to determine the Inverter Voltage.

Analysis of dc-Link Voltage Switching Ripple in

The three-phase voltage source inverter (VSI) is de facto standard in power conversion systems. To realize high power density systems, one of the items

Inverter Basics | inverter

Dec 29, 2023 · An inverter takes input from a DC (direct current) power supply and generates an AC (alternating current) output, typically at a voltage

What Does an Inverter Do

6 days ago · What Does an Inverter Do ? Inverters are also called AC Drives, or VFD (variable frequency drive). They are electronic devices that can turn DC

CSM_Inverter_TG_E_1_2

Mar 31, 2019 · The regenerative braking function uses the built-in or an external regenerative braking circuit to decrease the internal DC voltage of the inverter by converting the

AKX00057-1

Jul 26, 2018 · In order to control the output voltage supplied to a motor, the DC voltage fed to the inverter is varied by a voltage booster. To rotate a motor at low RPM, the DC voltage is set to

How do I calculate the DC link current of a three

The DC link current Idc of the inverter can be calculated from electrical analysis of the inverter. If your active output power is Po= 3 IphVph cos phi and the

Voltage Control Methods of Inverter – PWM

Feb 12, 2022 · In motor control applications, inverters handle the control of circuit voltage along with frequency so that the saturation of motor magnetic circuits

inverter

Jul 15, 2025 · Confusion about the rated voltage of a Permanent magnet synchronous motor. I''m currently trying to do a motor control experiment and

SINAMICS S120 Motor Modules as a DC-DC converter for

Aug 31, 2023 · By using the Motor Module functioning as a DC-DC converter, connected inverters can be operated with defined supply voltages. The customer can specify the voltage level

(PDF) Analysis of DC-Link Voltage Ripple in

Oct 1, 2018 · In this paper, the DC-link voltage ripple is analyzed for an inverter without electrolytic capacitor. As the capacitance density of non-electrolytic

Analysis and Reduction of Current and Voltage Ripple in DC

Nov 23, 2022 · In this article, switching strategies for dc-link current and voltage ripple reduction have been studied. The considered topology is a neutral-point clamped three-level (NPC-3L)

Electric Motor Inverter Explained

Jun 23, 2025 · It converts the battery''s direct current (DC) into the alternating current (AC) needed by the motor, controlling torque, speed, and regenerative braking. This core function ties

EV Motor Inverter

Feb 5, 2025 · An electric vehicle motor inverter is an essential electronic device that converts direct current (DC) electricity from the EV battery into alternating

All About DC Inverter Air Condtioners (2025)

Apr 9, 2025 · In modern heating, ventilation, and air conditioning (HVAC) units, a direct current (DC) inverter is motor control technology that gives the system

6 FAQs about [DC voltage of motor inverter]

What is AC motor inverter?

AC motor inverters are devices that convert direct current (DC) into alternating current (AC) to control the speed and torque of electric motors. They are essential for improving energy efficiency in various applications, such as fans, pumps, and conveyor systems. 1. Functionality 2. Types 3. Applications 4. Benefits 5. Considerations

What is the output voltage of an inverter?

It describes the output voltage of an inverter, which converts direct current (DC) from sources like batteries or solar panels into alternating current (AC). The output voltage of an inverter is determined by the DC input voltage and the modulation index.

How does an inverter control a motor?

An inverter uses this feature to freely control the speed and torque of a motor. This type of control, in which the frequency and voltage are freely set, is called pulse width modulation, or PWM. The inverter first converts the input AC power to DC power and again creates AC power from the converted DC power using PWM control.

What is an electric vehicle inverter?

An inverter is a device that converts direct current (DC), which is supplied from a battery, into alternating current (AC). A motor in an electric vehicle runs on this alternating current, which thus drives the wheels. To improve overall energy efficiency of the electric vehicle, the energy loss of the inverter should be reduced to the minimum.

What is a DC inverter?

The IPM inverts the DC into AC - hence the term ‘Inverter’. The control method is known as ‘PWM’ for 'Pulse Width Modulation'. This means the DC is switched on and off very quickly (chopped) by the Transistor switches.

How do inverters convert DC to AC?

Conversion process: Inverters initially take DC power from sources like batteries or solar panels. They use power electronic devices called transistors to switch the DC voltage rapidly. This switching creates a pulsed output that imitates AC waveform.

Industry Information

- How to connect the battery cabinet to the communication high voltage cabinet

- EU Small Household Solar Lights

- Inverter 20n60

- Monaco Solar Tiles

- Malaysia power grid energy storage price and application

- Solar cell energy storage device

- The role of booster pumps in energy storage power stations

- How big a photovoltaic panel is needed for 600w solar energy

- Where to build flywheel energy storage for Luxembourg solar base station

- 2 lithium batteries for electric tools connected in series

- Energy storage components in control systems

- There are several specifications and models of rural rooftop photovoltaic panels

- Bhutan ESS energy storage system

- Photovoltaic panel current 260w

- Hybrid Energy and State Grid cooperate on 5G base stations

- How to replace the battery energy storage system equipment of the communication base station

- Demand for photovoltaic energy storage batteries

- Phase change station cabinet battery cabinet

- The best brand of photovoltaic energy storage cabinet

- Small inverter 12v to 220v

- Single phase circuit breaker in Dominica

- Photovoltaic energy storage current trend

- Camping photovoltaic solar panels

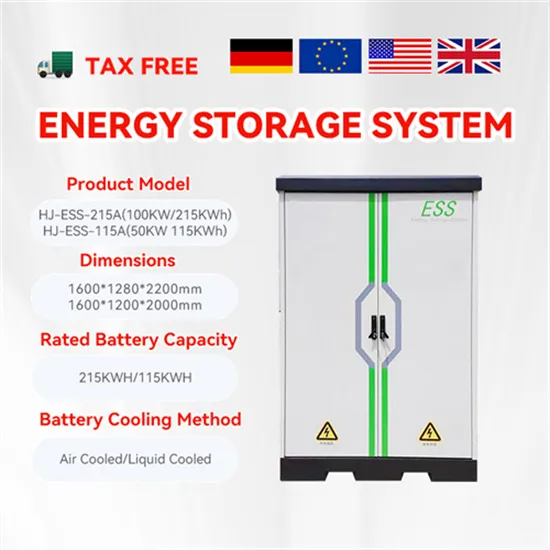

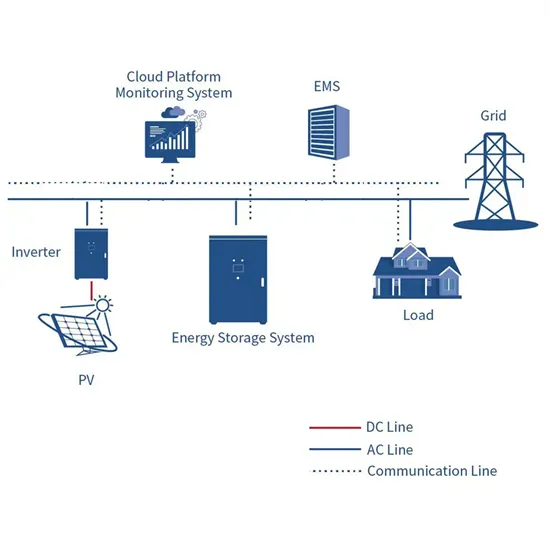

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.