Application of Sodium Sulfate Na2SO4 in Photovoltaic Glass

Feb 13, 2025 · Get exclusive access to Application of Sodium Sulfate Na2SO4 in Photovoltaic Glass Industry details at Guangzhou Hongzheng Trade Co., Ltd., a renowned FeCL3 Ferric

Towards improved cover glasses for

Photovoltaic (PV) module assembly is material-demanding, and the cover glass constitutes a significant proportion of the cost. Currently, 3-mm-thick glass is

Glass Application in Solar Energy Technology

Apr 28, 2025 · This chapter examines the fundamental role of glass materials in photovoltaic (PV) technologies, emphasizing their structural, optical, and

Contribution of Na+ from Glass to PID-s in Solar Modules:

Jun 10, 2022 · Potential-Induced Degradation of the Shunting type (PID-s) has been linked to Na, but the source is unclear. In this paper we evaluate the ion migration kinetics in encapsulant

Sodium Metal Uses | Essential Insights and

Nov 23, 2024 · Sodium metal uses, a highly reactive and essential element, plays a crucial role in various industries and scientific applications. While its use in

Failure modes of silicon heterojunction photovoltaic

Dec 1, 2024 · First, the glass-glass configuration with soda-lime glass shows significant VOC and ISC losses due to depassivation of the cell with current production loss of certain areas by the

Scalable, Self‐Contained Sodium Metal Production Plant

Jul 13, 2017 · In this chapter, we present a detailed design study of a novel, scalable, self-contained solar powered electrolytic sodium (Na) metal production plant meant to enable a

Solar Glass: What Is It & What Is Its Role In Solar

Jul 23, 2021 · If the supply of PV glass exceeds the demand, it is impossible to switch directly from the float glass production line. The deep processing

Effect of sodium on recrystallization and photovoltaic properties of

Oct 1, 2012 · During processing of CdTe solar cells, sodium can diffuse from the glass substrate into the active layers and can considerably affect CdTe solar cell properties. In this paper, the

The application of Sodium Sulphate in the photovoltaic glass

The use of photovoltaic glass Photovoltaic glass is an encapsulation material used in photovoltaic modules,its function is: ①Encapsulates and protects the crystalline silicon wafers, the core

The application of Sodium Sulphate in the

The use of photovoltaic glass Photovoltaic glass is an encapsulation material used in photovoltaic modules,its function is: ①Encapsulates and protects the

Solar Glass: What Is It & What Is Its Role In Solar

Jul 22, 2021 · Performance requirements of solar glass The solar glass must have good light transmittance. Generally speaking, the light transmittance of

Role of NaCl on structural, optical and mechanical properties

May 1, 2025 · Glass substrate prepared from photovoltaic glass wastes exhibited a transmittance of 83.60%, which is similar to that of commercial soda-lime glass (84.76%), which was being

(PDF) Glass Application in Solar Energy Technology

May 3, 2025 · This chapter examines the fundamental role of glass materials in photovoltaic (PV) technologies, emphasizing their structural, optical, and spectral conversion properties that

Glass/Glass Photovoltaic Module Reliability and

Aug 3, 2021 · Glass/glass (G/G) photovoltaic (PV) module construction is quickly rising in popularity due to increased demand for bifacial PV modules, with

The role of sodium in photovoltaic devices under high voltage

Dec 1, 2013 · Soda-lime glass with a concentration of sodium around 13–15% is widely used both as cell substrate and as front layer in PV modules. Glass is not a static material and Na

Sodium induced grain growth, defect passivation and

Jul 1, 2016 · Sodium diffusion from soda lime glass (SLG) during high temperature annealing is known to play a crucial role in affecting the grain growth and defect passivation in

Silica Sand for Solar Glass Manufacturing: A

Nov 25, 2024 · Solar glass, a critical component in photovoltaic (PV) panels, depends on the superior optical and mechanical properties provided by high

Photovoltaic-Sodium Ion Battery Integrated Systems

Aug 7, 2025 · The production of photovoltaic panels involves the use of various materials, including silicon, glass, and metals. While these components are generally abundant, their

Failure modes of silicon heterojunction photovoltaic

Aug 3, 2025 · In fact, the soda-lime glass is the 52 main glass used for module encapsulation due to its low cost and high availability [11]. It is 53 well known in the PV industry that under a

Most photovoltaic glass companies choose sodium

Most of the photovoltaic glass enterprises choose sodium pyroantimonate as a clarifying agent, due to sodium pyroantimonate in the decomposition temperature within the country, do not

The main components of photovoltaic glass

Dec 31, 2024 · Photovoltaic glass is a type of special glass that integrates solar photovoltaic modules, capable of generating electricity by utilizing solar

Scalable, Self‐Contained Sodium Metal Production Plant

Jul 13, 2017 · The energy conversion efficiency of the photovoltaic (PV) device panels is therefore a critical parameter for determining the amount of Na metal that can be produced by the self

Glass/glass photovoltaic module reliability and degradation:

Aug 3, 2021 · Abstract Glass/glass (G/G) photovoltaic (PV) module construction is quickly rising in popularity due to increased demand for bifacial PV modules, with additional applications for

Unveiling Sodium Diffusion Kinetics and Locking

May 23, 2025 · This study demonstrates that strategic control of Na diffusion dynamics is essential for unlocking the full potential of CZTSSe photovoltaic devices. By synergistically

This Is How PV Bill of Materials Impacts Module Production

Jul 22, 2024 · PV glass production relies on raw materials like low-iron silica sand, soda ash, dolomite, limestone, sodium pyroantimonate, and significant energy resources. Low-iron silica

CN116143169A

The invention discloses a sodium pyroantimonate for photovoltaic glass and a preparation method thereof. Firstly, antimony trioxide is used as a raw material, water is used as a solvent, and

Photovoltaic glass on it? What are its pros and cons?

May 10, 2024 · Photovoltaic glass, also known as "photoelectric glass", is a special glass that presses solar photovoltaic modules, can use solar radiation to generate electricity, and has

Solar Photovoltaic Glass: Classification and

Jun 26, 2024 · Demand for solar photovoltaic glass has surged with the growing interest in green energy. This article explores ultra-thin, surface-coated, and

Sodium Diffuses from Glass Substrates through

Jun 25, 2022 · Most thin-film photovoltaic modules are constructed on soda-lime glass (SLG) substrates containing alkali oxides, such as Na 2 O. Na may

6 FAQs about [Sodium metal production of photovoltaic glass]

Does Na incorporation improve photovoltaic performance?

Experimental results demonstrated that the PCE of solar cells prepared with quartz substrates decreased significantly by ≈33% (Figure S10 and Table S3, Supporting Information), indicating that Na incorporation plays a crucial role in enhancing photovoltaic performance.

Why do CZTSSe solar cells use soda-lime glass?

This is also a major reason why most CZTSSe solar cells use soda-lime glass as the substrate. [35 - 37] Specifically, when using soda-lime glass as the substrate, under high-temperature conditions, Na diffuses toward the absorber layer. This diffusion behavior promotes the growth of CZTSSe grains and passivates interface defects.

Is sodium induced shunting a problem in crystalline Si solar modules?

Abstract: Sodium induced shunting continues to be a challenging issue in crystalline Si solar modules. Potential-Induced Degradation of the Shunting type (PID-s) has been linked to Na, but the source is unclear. In this paper we evaluate the ion migration kinetics in encapsulant material under operational conditions.

Does spin-coating increase Na content in soda-lime glass?

Before spin-coating, the cleaned Mo-coated substrates were preheated for 10 min to increase the Na content in the Mo surface layer (the absence of a SiO 2 barrier layer in the Mo layer does not affect the upward diffusion of Na from the soda-lime glass).

Is na migration from glass through Eva too slow?

Implementing these results in breakthrough time simulations indicates that Na migration from the glass through EVA is too slow to account for experimentally observed PID-s degradation indicating contamination during production as the most likely source. Need Help?

How do you make a pre-0 film from a soda-lime glass substrate?

Subsequently, a Na-free precursor solution was spin-coated onto the Mo-coated soda-lime glass substrates and heated at 300 °C for 2 min to form the precursor film; the film prepared under these conditions served as the reference sample and was named Pre-0.

Industry Information

- Where to put the inverter on the roof of photovoltaic BESS

- Hydraulic transmission system of wind turbine

- Communication base station solar power plant photothermal equipment information

- Energy storage power station electricity price settlement

- Is there any pollution around the photovoltaic glass factory

- Which is the best uninterruptible power supply in Marseille

- Wholesale 300wh power station in Honduras

- Main breaker switch in China in Bangladesh

- How many watts does solar energy have per square meter

- Wholesale gfci breaker wiring in Japan

- Chilean lithium energy storage power supply customization company

- West Africa Solar System Wholesale

- Wholesale 4000 amp switchgear in Azerbaijan

- Huawei Communication Base Station Supercapacitor Research Institute

- Stockholm large corrugated container wholesale

- Unit cost of photovoltaic glass production

- Valletta Home Yard Solar Lights

- Communication base station power supply configuration

- What is the size of the photovoltaic panels of 660

- Stockholm photovoltaic inverter installation company

- Are all 60V inverters universal

- Energy storage cabinet battery 9v photovoltaic

- Kuala Lumpur container villa wholesale

Commercial & Industrial Solar Storage Market Growth

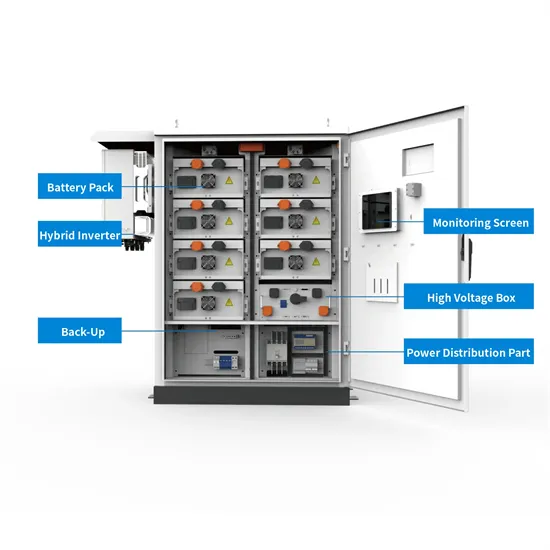

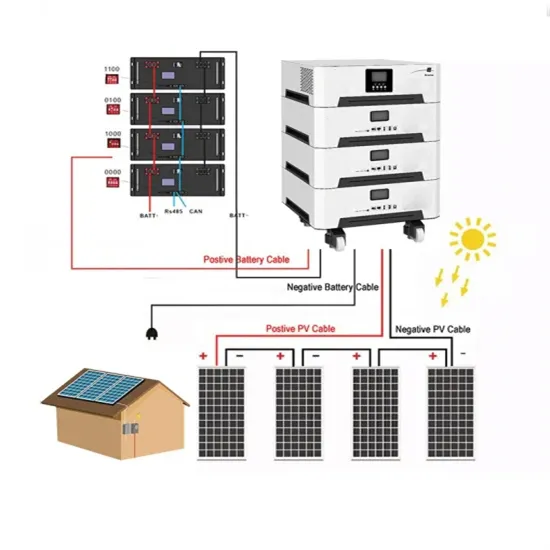

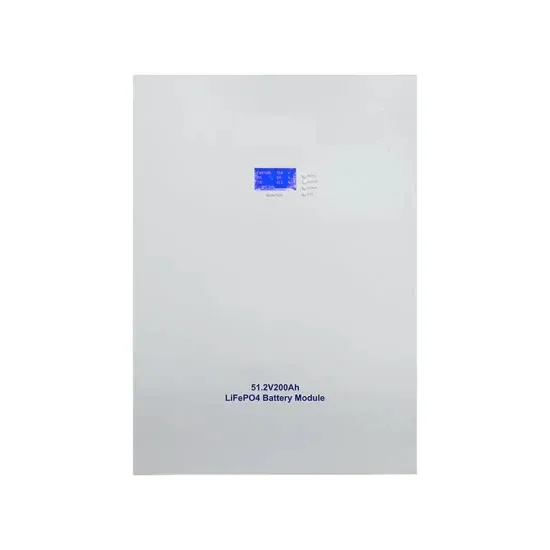

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.