444

Mar 17, 2025 · 444 - a formulation for thermal shock resistance Kenneth Andrew Domann*, Ceramic Engineer and Larry Finn**, Laboratory Manager discuss a formulation that has helped

Thermal Shock Effect on the Glass Thermal Stress Response and Crack

Jan 1, 2013 · Thermal shock is always caused by rapid and extreme temperature changes, which is very dangerous for the glass integrity. Therefore, the objective of this work is to investigate

Thermo-mechanical stress modelling and fracture analysis

Mar 1, 2025 · Thermo-mechanical stress modelling and fracture analysis on ultra-thin silicon solar cell based on super multi-busbar PV modules

New design for photovoltaic-thermal panels

Feb 28, 2024 · An international research team has proposed a novel photovoltaic-thermal (PVT) module design that purportedly reduces the risks of cracking in

Thermal Shock

Aug 8, 2024 · From the laboratory standpoint, there are three main types of glass used today: borosilicate, quartz, and soda lime or flint glass. Borosilicate glass is made to withstand

How to Prevent Your Solar Panels From Cracking

Aug 16, 2025 · The glass on photovoltaic panels is designed to withstand rough weather and extensive use, but certain situations can compromise the module

Can Solar Panel Glass Break? | IWS

Feb 6, 2020 · Thermal Shock Can Crack Solar Panel Glass Have you ever poured cold liquid into a hot glass or placed a straight-from-the-oven glass

Numerical Simulation of Thermal Shock for Glass-Glass

Mar 27, 2025 · In this chapter, the attention is given to the use of numerical models and Finite Element (FE) methods for the transient heat transfer, thermal analysis of glass-glass BIPVs in

Thermal Shock

Thermal shock or fracturing can occur for a number of reasons. IQ understand the fundamental issues and glass types and have identified safe ways to reduce

Numerical Simulation of Thermal Shock for Glass-Glass

Mar 27, 2025 · Abstract and Figures Glass-glass photovoltaic (PV) technologies for building integrated (BIPV) applications are increasingly used in construction, due to several advantages.

Cracking Down on PV Module Design: Results from

Sep 5, 2023 · Cracking Down on PV Module Design: Results from Independent Testing Cracks in solar cells are typically so small that they cannot be detected by eye – yet they can reduce a

A Review of Photovoltaic Module Failure and

Jan 9, 2024 · This paper conducts a state-of-the-art literature review to examine PV failures, their types, and their root causes based on the components of PV

Performance of photovoltaic panels with different

Feb 1, 2025 · The glass fracture and pyrolysis of the internal thermoplastic materials were observed under thermal radiation. The average breakage time of glass in PV panels showed

Meeting the Challenge of PV Module Glass

Dec 12, 2023 · Detecting PV module glass cracks is slow, manual and labor-intensive Thinner glass cracks more easily — and it''s also harder to spot. Due

FB62-19 Thermal Stress in Heat-Treated Spandrel Glass

Aug 6, 2021 · Recently, attention has been drawn to several incidents in which spandrel glass has experienced solar-induced thermal stress breakage. Although a relatively rare occurrence,

A thermal model for photovoltaic panels under varying atmospheric

Aug 1, 2010 · A new thermal model is proposed that incorporates atmospheric conditions; effects of PV panel material composition and mounting structure. Experimental results are presented

Assessment of long term reliability of photovoltaic glass–glass modules

Apr 1, 2015 · Quantifying the reliability of photovoltaic (PV) modules is essential for consistent electrical performance and achieving long operational lifetimes.

Effect of Coefficient of Thermal Expansion (CTE) Mismatch of

Jan 1, 2017 · Effect of Coefficient of Thermal Expansion (CTE) Mismatch of Solder Joint Materials in Photovoltaic (PV) Modules Operating in Elevated Temperature Climate on the Joint''s

Glass/Glass Photovoltaic Module Reliability and

Aug 3, 2021 · Glass/glass (G/G) photovoltaic (PV) module construction is quickly rising in popularity due to increased demand for bifacial PV modules, with

Mechanism of stress generation during thermal shock

Dec 11, 2024 · the glass container industry, the example of rapid heat transfer is termed thermal shock. The constraint that is present is due to the relatively poor thermal conductivity of glass

Window-Integrated PV Glass: The Future of Solar

Feb 19, 2025 · Photovoltaic (PV) glass stands at the forefront of sustainable building technology, revolutionizing how we harness solar energy in modern

Numerical Simulation of Thermal Shock for Glass-Glass

Mar 27, 2025 · The attention is focused on the heat transfer transient analysis for first crack and failure time detection due to thermal shock of the exposed glass cover. The simulations give

Thermal Stress Fractures In Glass

Nov 15, 2024 · Window Wise explain thermal stress or ''shock'' cracks, which can occur in window panes, and the streps you can take to avoid them.

Resist Thermal Shock Through Viscoelastic

May 11, 2024 · Through the results of morphology evolution, we think that perovskite materials and devices suffer from static thermal stress during

Numerical Simulation of Thermal Shock for Glass-Glass

Mar 27, 2025 · The average breakage time of glass in PV panels showed an increasing trend with increasing inclination of the PV panels. Moreover, when the PV panels were tilted beyond 30°,

(PDF) Joint Research Project (in progress): Draft

Jun 20, 2022 · For the design of façade and roof glazing, loads due to dead weight, climatic loads (IGU - pressure differences), wind and snow are well

Useful information on Glass breakage due to thermal

Mar 21, 2022 · Prevention of glass breakage due to thermal overloading Intense, uneven heating can lead to high levels of stress within the glass and, in extreme cases, trigger what is known

Thermal Stress and Strain of Solar Cells in Photovoltaic

Jan 1, 2011 · The long-term stability of photovoltaic (PV) modules is largely influenced by the module''s ability to withstand thermal cycling between −40°C and 85°C. Due to different

(PDF) Glass Application in Solar Energy Technology

May 3, 2025 · This chapter examines the fundamental role of glass materials in photovoltaic (PV) technologies, emphasizing their structural, optical, and spectral conversion properties that

What is Thermal Shock? (with picture)

May 21, 2024 · The type of glass traditionally used to make Pyrex® is called borosilicate glass, due to the addition of boron, which prevents shock by

Physical Properties of Glass and the Requirements for

Feb 16, 2011 · Physical Properties of Glass and the Requirements for Photovoltaic Modules Dr. James E. Webb Dr. James P. Hamilton

Managing Thermal Stress Breakage

Aug 20, 2024 · Learn how to prevent a thermal break in glass. Our stress analysis tool helps to ensure the right glass is being used for your commercial project.

Numerical Investigation on the Thermo‐Mechanical

Aug 14, 2025 · Failure detection for the examined glass–glass PV module: (a) thermal difference at the exposed and unexposed glass surfaces, with corresponding (b) thermal stresses at

Joint Research Project (in progress): Draft

Keywords Thermally induced stresses, thermal breakage, façade glazing, insulating glass unit, building-integrated (BIPV) glass-glass photovoltaic modules, German meteorological data

6 FAQs about [Thermal shock of photovoltaic glass]

What is a thermal shock in a building fire?

Keywords: Thermal shock; Thermal stress; Glass; Crack; Finite element method 1. Introduction In a building fire, the glass is heated gradually in the early stage of fire; however, if flashover occurs in a compartment, the glass is heated rapidly, which could result in a thermal shock.

Does temperature rise affect glass thermal stress initiation & propagation?

Thermal shock is always caused by rapid and extreme temperature changes, which is very dangerous for the glass integrity. Therefore, the objective of this work is to investigate the effect of the rate of temperature rise on the glass thermal stress building up, and crack initiation and propagation, using a finite element method.

How does thermal shock occur?

Thermal shock occurs when a thermal gradient causes different parts of an object to expand by different amounts. This differential expansion can be understood equally in terms of stress or strain. At some point in time, this stress can exceed the strength of the material, causing a crack to form.

Why do photovoltaic modules have a long-term stability?

The long-term stability of photovoltaic (PV) modules is largely influenced by the module’s ability to withstand thermal cycling between −40°C and 85°C. Due to different coefficients of thermal expansion (CTE) of the different module materials the change in temperature creates stresses.

What causes thermal stress on glass?

Thermal stress is caused by temperature difference upon the glass, if the temperature rise T (x, y, z) with respect to the original state is known, then the associated deformation can be considered easily. For glass, the temperature rise T results in a uniform strain, which depends on the coefficient of linear expansion of the material .

What causes a glass to wave at a lower temperature?

This waving is caused by the thermal shock on the glass, which could cause the glass break at lower temperature difference. When the temperature rises with a slower rate, the thermal stress growth histories are similar with each others.

Industry Information

- South Korean supercapacitor manufacturer

- Which type of energy storage product does PV storage belong to

- Armenian coal-to-electricity energy storage equipment manufacturer

- How many 5G transformation base stations does Nepal have

- Romanian outdoor communication battery cabinet export company

- Solar Gel Inverter Battery

- Jamaica power plant clean photovoltaic energy

- 670wp monocrystalline photovoltaic panel

- Ankara Solar Water Pump Wholesalers

- Jordan inverter manufacturers quote

- 6000w solar inverter for sale in Lisbon

- Voc uninterruptible power supply requirements

- 6g communication power base station

- Ess mechanical increase price

- What is the size of the battery cabinet in centimeters

- Baku shingled solar panels

- Professional Solar Photovoltaic System

- Uganda Industrial Energy Storage

- How many watts is the inverter 60a

- Energy storage cabinet for base station of telecommunication company

- Battery cabinet 25kw

- Large-scale sun shed photovoltaic panel manufacturer

- Netherlands 96v to 220v inverter quotation

Commercial & Industrial Solar Storage Market Growth

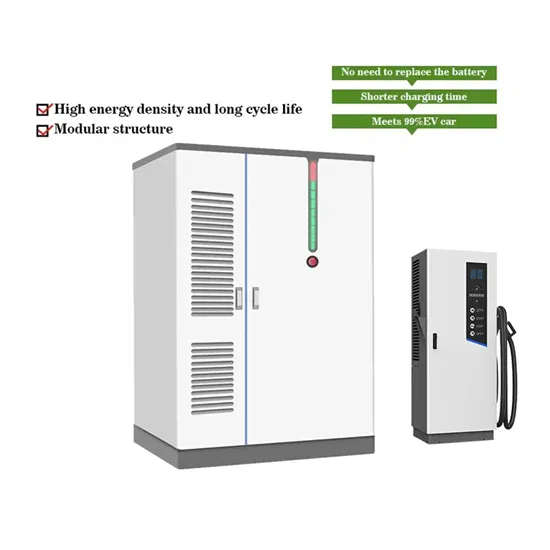

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.