Ventilation condition effects on heat dissipation of the lithium

Nov 1, 2024 · Therefore, a lithium-ion battery energy storage cabin requires an efficient ventilation condition to ensure fire safety. This work investigates the effects of ventilation mode,

A Comprehensive Analysis of Thermal Heat

Apr 28, 2025 · This study presents a comprehensive thermal analysis of a 16-cell lithium-ion battery pack by exploring seven geometric configurations under

Air cooling and heat dissipation performance of multi-layer battery

For multi-layer battery cabinets, experiments were first established to verify the flow field inside the cabinet, ensuring the accuracy of simulation results. Then, the effects of different air supply

Numerical Simulation and Optimal Design of Air Cooling Heat Dissipation

Jan 1, 2022 · Due to the thermal characteristics of lithium-ion batteries, safety accidents like fire and explosion will happen under extreme conditions. Effective thermal management can inhibit

电化学储能系统电池柜散热的影响因素分析<sup>*</sup>

Abstract: The electrochemical energy storage system is an important grasp to realize the goal of double carbon. Safety is the lifeline of the development of electrochemical energy storage

Experimental investigation on thermal management of lithium-ion battery

Apr 1, 2022 · In this paper, the temperature distribution of the battery along the height direction is obtained. The thermal management analysis of two 100Ah lithium-ion batteries in series is

Numerical Simulation and Optimal Design of Air Cooling

Jan 1, 2022 · This paper studies the air cooling heat dissipation of the battery cabin and the influence of guide plate on air cooling. Firstly, a simulation model is established according to

power dissipation

Jul 15, 2021 · The number on the paper has a different meaning than Q. Heat is generated from other than effective power. Effective power is used to drive the

Heat dissipation investigation of the power lithium-ion battery

Nov 15, 2020 · In this work, the physical and mathematical models for a battery module with sixteen lithium-ion batteries are established under different arrangement modes based on the

Energy storage battery cabinet heat dissipation

The results show that the heat generation of the battery in the discharge process is higher than that of the charging process, and the air from the top of the battery pack can achieve a better

Energy storage battery cabinet heat dissipation

What is the temperature distribution of a battery cabinet? ture at various heights of the battery cabinet. The batteries of the lower height level have a temperature about 25°C; the

Development and optimization of hybrid heat dissipation

Oct 1, 2024 · Experiments investigated thermal properties, phase change phenomena, and optimal concentrations of nanocarbon inclusions. This study presents the development and

2025-01-8193: Research on Heat Dissipation of Cabinet of

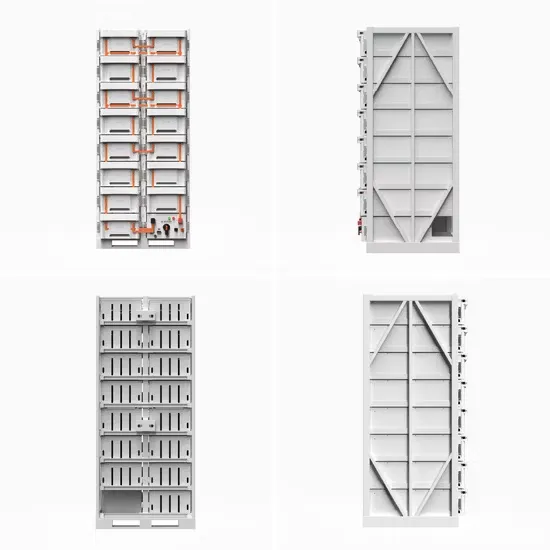

According to the actual size of a company''s energy storage products, this paper also considered the liquid cooling cooling system, air cooling cooling system and lithium-ion battery module

Study on the thermal interaction and heat dissipation of

Dec 1, 2017 · The battery pack is commonly consisted by hundreds of cylindrical Lithium-Ion battery cells in several strings. Because the distance among battery cells is only a few

Energy storage battery cabinet heat dissipation method

LIQUID COOLING SOLUTIONS For Battery Energy Storage allowing lithium-ion batteries to reach higher energy density and uniform heat dissipation. Our experts provide proven liquid

Heat dissipation analysis and optimization of lithium-ion batteries

Jun 15, 2022 · The design of thermal management system affects the safety, cycle life, and operating cost of lithium-ion battery. This paper discusses the structure

Analysis of Influencing Factors of Battery Cabinet Heat Dissipation

Abstract The electrochemical energy storage system is an important grasp to realize the goal of double carbon. Safety is the lifeline of the development of electrochemical energy storage

Numerical simulation study on the impact of convective heat

Dec 1, 2024 · To enhance the accuracy of lithium battery thermal models, this study investigates the impact of temperature-dependent convective heat transfer coefficients on the battery''s air

Comprehensive Analysis of Thermal Dissipation in Lithium-Ion Battery

Feb 11, 2025 · This study investigates the thermal performance of a 16-cell lithium-ion battery pack by optimizing cooling airflow configurations and integrating phase change materials

Heat dissipation optimization of lithium-ion battery pack

Nov 5, 2019 · The excessively high temperature of lithium-ion battery greatly affects battery working performance. To improve the heat dissipation of battery pack, many researches have

Analysis of Influencing Factors of Battery Cabinet Heat Dissipation

The electrochemical energy storage system is an important grasp to realize the goal of double carbon. Safety is the lifeline of the development of electrochemical energy storage system.

Simulation of Active Air Cooling and Heat Dissipation of Lithium

Dec 31, 2023 · The advantages of Lithium-ion batteries can be concluded as specific energy and power, good cycling performance, and environmental friendliness. However, based on the

Maintaining Compliance in the VRLA Battery Room

Dec 20, 2022 · Thermal runaway is a condition caused when the internal heat generation inside a battery exceeds the rate of heat dissipation. In VRLA batteries, higher charge currents have an

Simulation of heat dissipation model of lithium-ion

Zhang Junxia [4] takes the heat dissipation management of lithium batteries and lithium battery pack as the primary topic of electric vehicle application. By using computational fluid dynamics

Thermal Simulation and Analysis of Outdoor Energy Storage Battery

Jan 8, 2024 · We studied the fluid dynamics and heat transfer phenomena of a single cell, 16-cell modules, battery packs, and cabinet through computer simulations and experimental

principle of heat dissipation system of energy storage cabinet

Design and Optimization of Heat Dissipation for a High-Voltage Control Box in Energy Storage Systems The high-voltage control box is positioned at the upper part of the energy storage

Ventilation condition effects on heat dissipation of the lithium

Nov 1, 2024 · Due to the high energy density of the lithium-ion battery, lots of heat, smoke, and toxic gas will be rapidly produced during thermal runaway and accumulate at the extreme

Review on the heat dissipation performance of battery pack

Jan 1, 2014 · This paper reviews the heat dissipation performance of battery pack with different structures (including: longitudinal battery pack, horizontal battery pack, and changing the

Lithium Battery Charging Cabinet: The Essential Guide to

May 9, 2025 · The widespread use of lithium-ion batteries across various industries and applications—ranging from power tools to electric vehicles—has led to increasing concern

Analysis of Influencing Factors of Battery Cabinet Heat Dissipation

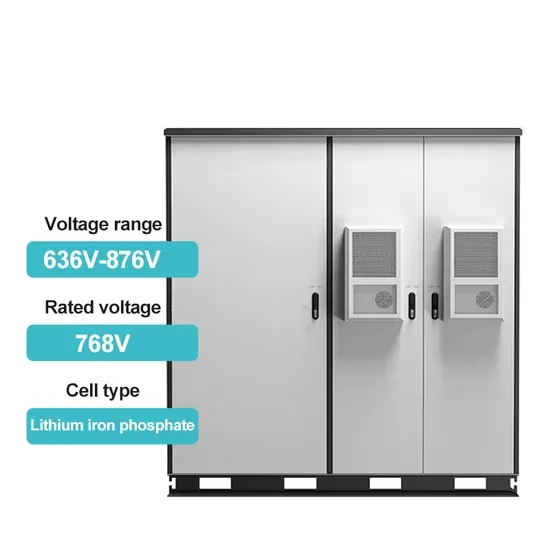

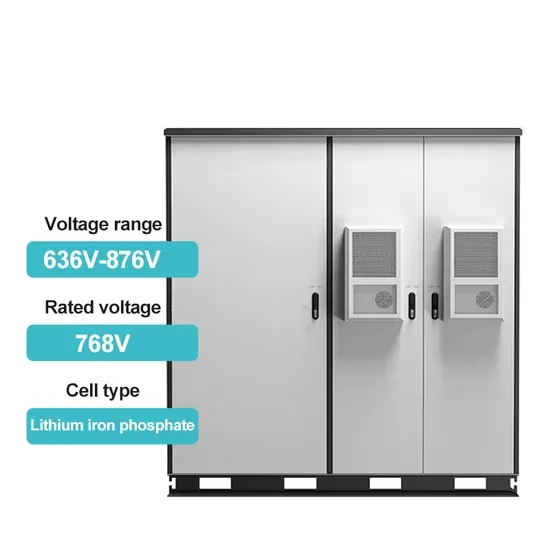

For the lithium iron phosphate lithium ion battery system cabinet: A numerical model of the battery system is constructed and the temperature field and airflow organization in the battery cabinet

6 FAQs about [Heat dissipation of lithium battery station cabinet]

Does guide plate influence air cooling heat dissipation of lithium-ion batteries?

Due to the thermal characteristics of lithium-ion batteries, safety accidents like fire and explosion will happen under extreme conditions. Effective thermal management can inhibit the accumulation and spread of battery heat. This paper studies the air cooling heat dissipation of the battery cabin and the influence of guide plate on air cooling.

Does natural convection remove heat from lithium-ion batteries?

A two-dimensional, transient heat-transfer model for different methods of heat dissipation is used to simulate the temperature distribution in lithium-ion batteries. The experimental and simulation results show that cooling by natural convection is not an effective means for removing heat from the battery system.

Can a transient thermal model predict the heat dissipation behavior of lithium-ion batteries?

A two-dimensional transient thermal model has also been developed to predict the heat dissipation behavior of lithium-ion batteries. Finally, theoretical predictions obtained from this model are compared with experimental values. 2. Experimental

Why are temperature distribution and heat dissipation important for lithium-ion batteries?

Consequently, temperature distribution and heat dissipation are important factors in the development of thermal management strategies for lithium-ion batteries.

Can a heat pipe improve heat dissipation in lithium-ion batteries?

Thus, the use of a heat pipe in lithium-ion batteries to improve heat dissipation represents an innovation. A two-dimensional transient thermal model has also been developed to predict the heat dissipation behavior of lithium-ion batteries. Finally, theoretical predictions obtained from this model are compared with experimental values. 2.

Do lithium ion batteries have heat dissipation?

Although there have been several studies of the thermal behavior of lead-acid , , , lithium-ion , and lithium-polymer batteries , , , , heat dissipation designs are seldom mentioned.

Industry Information

- Belgrade Photovoltaic Energy Storage Distribution

- Top 10 photovoltaic glass suppliers

- Bangladesh Supercapacitor Company

- Communication base station hybrid energy module development plan

- Brazilian solar street lights

- Light-transmitting thin-film solar photovoltaic panels

- Grid storage in southern Belgrade

- Photovoltaic inverter protection temperature

- Indonesia Energy Storage Container Procurement Network System

- Solar light power storage price

- A manufacturer specializing in inverters in Paraguay

- 14500 lithium iron phosphate battery pack

- Power breaker switch for sale in France

- 60 lithium batteries assembled into a 32v battery pack

- Industrial Park Communication Base Station Photovoltaic Energy Storage System

- Belgian solar power generation system

- Power storage system function

- Solar power storage in China in Ghana

- 21700 battery cell 6058

- EK outdoor power supply two degrees of electricity

- Energy storage liquid cooling pack-level fire protection

- Communication green base station cost

- Algeria modified inverter manufacturer

Commercial & Industrial Solar Storage Market Growth

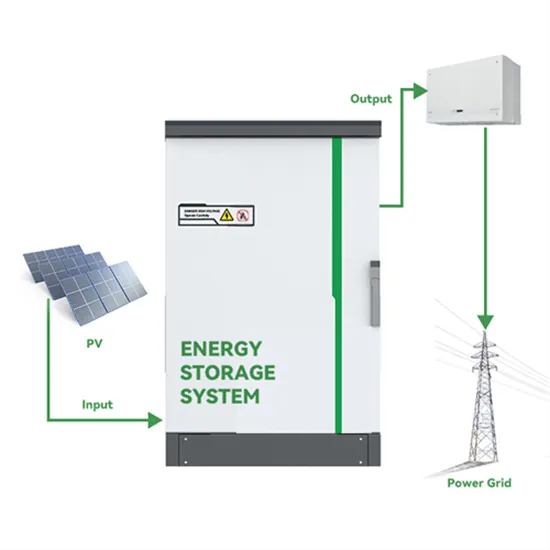

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.