Scientists achieve near-total recovery of rare

Apr 1, 2025 · After that, extracting them relies on glycine, an amino acid that is much milder and safer for the environment than chemicals used in previous

Amino Acid Assists in Recycling Rechargeable Batteries

Mar 11, 2025 · His primary research focuses on advanced materials for energy storage and environmental applications, with a particular emphasis on the development of sustainable

Amino acid as a multifunctional electrolyte additive for

Jan 3, 2025 · Lithium‑sulfur (Li−S) batteries are among the most promising candidates for advanced energy storage technology; however, their commercial viability is bottlenecked by

Artificial α-amino acid based on cysteine grafted

Mar 26, 2025 · Introduction The development of large-scale energy storage systems is of utmost importance to regulate the electricity flow between

Amino Acid Assists in Recycling Rechargeable Batteries

Aug 9, 2025 · The leaching efficiency is improved by a solid-solid re-duction mechanism, known as the battery effect, as well as the addition of the amino acid glycine. Lithium-ion batteries not

Tailoring amino-functionalized cellulose separators for

Jun 24, 2024 · This study aims to enhance cellulose separators for energy storage, focusing on achieving high security and superior electrolyte wetting properties. Bacterial cellulose (BC)

Amino Acid Leaching of Critical Metals from Spent Lithium

Abstract To reduce the exploitation of mine resources and decrease the harm to the environment caused by urban electronic wastes, the recovery of critical metals in secondary resources is

Zwitterionic materials for aqueous Zn-based energy storage

Mar 1, 2025 · Aqueous Zn-based energy storage (AZES) devices are promising candidates for large-scale energy storage systems. Nevertheless, AZES devices still face some critical

Reversible hydrogenation of carbon dioxide to formic acid

May 19, 2022 · Here we report an α-amino acid-promoted system for reversible CO2 hydrogenation to formic acid using a Mn-pincer complex as a homogeneous catalyst.

A multifunctional phenylalanine additive

Feb 12, 2024 · Aqueous Zn-based batteries, promising energy storage devices for grid-scale applications, are restricted by the limited reversibility of Zn anodes.

Amino Acid-Powered Recycling: A Green

Mar 12, 2025 · Scientists have developed a glycine-based eco-friendly recycling process for lithium-ion batteries, achieving 99.99% lithium recovery in just 15

Amino acid as a multifunctional electrolyte additive for

Feb 15, 2025 · Here we apply a single amino acid, L-leucine (Leu), as a liquid electrolyte additive to curtail these critical issues and enhance the performance of the battery. With an ultralow

<br>氨基酸作为多功能电解质添加剂,用于增强 Li-S 电池性能

Jan 3, 2025 · Amino acid as a multifunctional electrolyte additive for enhancing Li−S battery performance Lithium‑sulfur (Li−S) batteries are among the most promising candidates for

An improved green high-efficiency strategy using an amino acid

Feb 15, 2025 · An improved green high-efficiency strategy using an amino acid derivative as electrolyte additives for corrosion inhibition in alkaline Al-air battery

Amino acid as a multifunctional electrolyte additive for

Feb 15, 2025 · Lithium‑sulfur (Li−S) batteries are among the most promising candidates for advanced energy storage technology; however, their commercial viability is bottlenecked by

Amino acid promoted hydrogen battery system using Mn

Nov 10, 2022 · Amino acid promoted hydrogen battery system using Mn-pincer complex for reversible CO2 hydrogenation to formic acid | Frontiers in Energy

A hydrophobic layer of amino acid enabling

Aqueous rechargeable zinc ion batteries have attracted increased attention for large-scale energy storage owing to their cost-effectiveness, safety and high

Amino acid assists in recycling rechargeable batteries

Mar 11, 2025 · Current hydrometallurgical methods for the reprocessing of spent lithium-ion batteries are based on acid or ammonia leaching processes. However, excessive and

An amphoteric and hydrogen-bond-rich artificial α-amino acid

May 21, 2025 · Owing to its unique zwitterionic structure and abundant hydrogen bonds, the negolyte based on artificial α-amino acid molecule exhibits a very low capacity decay rate of

Enhancing the cycle life of Zinc-Nickel aqueous batteries by

May 1, 2025 · 3. Results and Discussion 3.1. Additive properties L-Histidine (His) is composed of an imidazole ring and an amino propionic acid residue. Due to the presence of the imidazole

Amino Acid Assists in Recycling Rechargeable Batteries

1 day ago · The leaching efficiency is improved by a solid-solid re-duction mechanism, known as the battery effect, as well as the addition of the amino acid glycine. Lithium-ion batteries not

Redox flow batteries charge up with peptide

Researchers have developed an organic redox flow battery that uses polypeptides as anolyte and catholyte materials. 1 The concept could help to

Sustainable supercapacitors using advanced hydrated amino acid

Jan 1, 2025 · In this work, we explore the concepts of molecular dynamics (MD) to investigate the energy storage capacity of supercapacitors (SCs) composed of amino acid-based ionic liquids

Energy storage | Nature Communications

6 days ago · An amphoteric and hydrogen-bond-rich artificial α-amino acid for highly durable aqueous redox flow batteries Organic redox flow batteries face solubility and stability challenges.

Amino acid as a multifunctional electrolyte additive for

Jan 3, 2025 · Lithium‑sulfur (Li−S) batteries are among the most promising candidates for advanced energy storage technology; however, their commercial viability is bottlenecked by

Are Amino Acids Energy Storage Substances? A Deep Dive

While not energy storage per se, amino acids are shaking up renewable energy tech. Chinese scientists recently achieved 99.99% lithium recovery from batteries using glycine (a simple

A bioinspired and degradable riboflavin-containing

May 20, 2025 · Inspired by Nature, we present a polypeptide-based organic redox-active material constructed from renewable feedstocks, L-glutamic acid (an amino acid) and riboflavin (vitamin

Amino Acid Extracts 99.99% of Lithium From Old Batteries

Mar 13, 2025 · The leaching efficiency is improved by a solid-solid reduction mechanism, known as the battery effect, as well as the addition of the amino acid glycine. Lithium-ion batteries not

Polypeptide organic radical batteries

May 5, 2021 · An environmentally friendly, all-organic radical battery is demonstrated, in which redox-active polypeptides perform as both cathode and anode materials, with a metal-free

About Us-Lithium Battery Company-Amino Battery

Today, our revolutionary non-toxic deep-cycle lithium iron phosphate batteries are replacing lead-acid batteries in home energy storage, vehicles, ships and

Versatile Protein and Its Subunit Biomolecules for Advanced

In this review, it is aimed to offer a comprehensive understanding of the properties of proteins and their subunits, and research progress of using these versatile biomolecules to address the

Chinese researchers announce battery recycling

Mar 24, 2025 · The invention uses tiny micro batteries to break down lithium, nickel, cobalt and manganese from a battery before the metals are extracted

Amino acid as a multifunctional electrolyte additive for

Semantic Scholar extracted view of "Amino acid as a multifunctional electrolyte additive for enhancing Li−S battery performance" by Justin Zhong et al.

Interfacial Adsorption Layers Based on Amino

Mar 26, 2025 · Aqueous zinc–iodine (Zn–I 2) batteries are promising candidates for large-scale energy storage due to the merits of low cost and high safety.

6 FAQs about [Amino acid battery energy storage]

Can amino acids recycle lithium ion batteries?

Researchers have created a method to recycle lithium-ion batteries using amino acids to recover 99.99% of lithium with minimal environmental impact.

How do lithium-ion batteries improve leaching efficiency?

The leaching efficiency is improved by a solid-solid reduction mechanism, known as the battery effect, as well as the addition of the amino acid glycine. Lithium-ion batteries not only power our mobile phones, tablets, and electric vehicles, they are also increasingly important as storage for volatile renewable energy.

How can we recover 99% of lithium from used batteries?

Scientists use an amino acid-based method to recover 99.99% of lithium from used batteries, offering a sustainable recycling solution.

Can glycine be used to extract metals from a battery?

To make this possible, the researchers combined two innovative ideas: using tiny “micro batteries” to break down the battery materials and adding the amino acid glycine to help extract the metals. These tricks allow the valuable metals to be recovered without using harsh chemicals. Glycine, a common amino acid, plays a crucial role in this method.

How can a battery be recycled?

The leaching efficiency is improved by a solid-solid reduction mechanism, known as the battery effect, as well as the addition of the amino acid glycine. A new strategy for recycling spent lithium-ion batteries is based on a hydrometallurgical process in neutral solution.

How to reprocess lithium ion batteries?

Current hydrometallurgical methods for the reprocessing of spent lithium-ion batteries are based on acid or ammonia leaching processes. However, excessive and repeated use of acids and bases increases the environmental impact and safety hazards. A pH neutral process would be safer and more environmentally friendly.

Industry Information

- Solar Base Station Supercapacitor Sheet Contracting Program

- Which 10kw energy storage is best in Solomon Islands

- Algiers can do photovoltaic energy storage

- Estimation of the benefits of independent energy storage power stations

- Energy storage cabinet construction site

- Photovoltaic glass silicon-based manufacturers

- EU energy storage lead-acid battery prices

- 60mw solar photovoltaic module

- Can the 220V inverter be used for charging

- Low voltage distribution cabinet GGD intelligent solar energy storage cabinet power generation system

- RV Outdoor Power Selection

- Add a photovoltaic panel to the solar lamp

- Home energy storage customers

- Uninterruptible Power Supply for Power Distribution in Honduras

- Benin voltage stabilizer inverter custom manufacturer

- Medium 12v step-up inverter 1500v

- Types of off-grid inverters

- 60W solar light replaces big battery

- Grid-connected and off-grid inverter

- Global Three Flywheel Energy Storage

- Enterprises engaged in energy storage power stations

- Andor photovoltaic energy storage battery cabinet system manufacturer

- Medium voltage energy storage power supply product standard

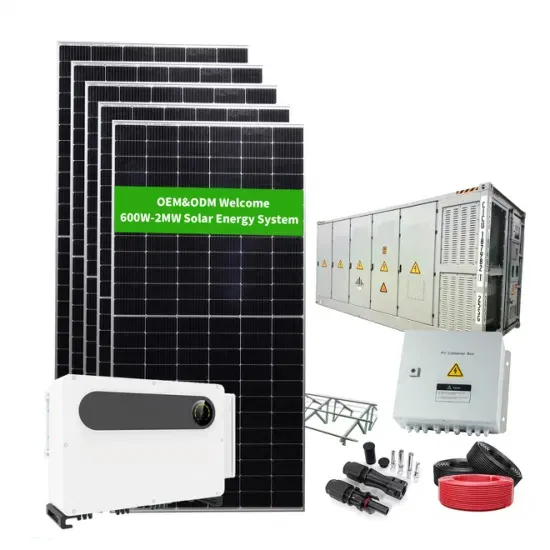

Commercial & Industrial Solar Storage Market Growth

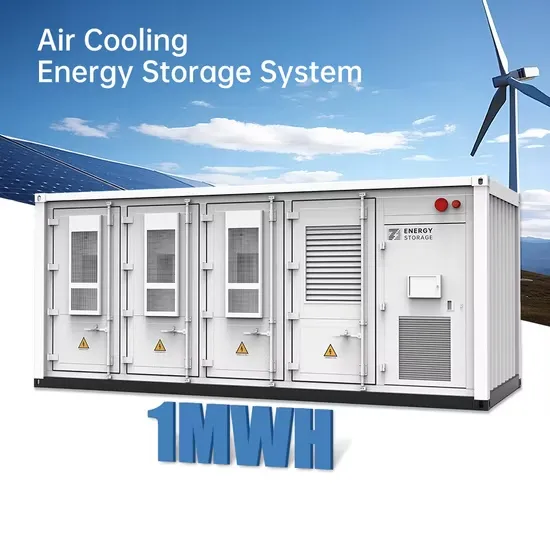

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.