Lead Acid Battery Production Line, Car Battery

Jul 14, 2025 · Lead Acid Battery Production Line, Car Battery Asembly Machine Equipment Customized, Find Details and Price about Battery Production Line

Inside a Battery Factory: How Lithium-ion PACK

Mar 11, 2025 · Introduction The lithium battery module PACK production line is a production line that combines multiple battery cells into a complete battery

Energy storage cabinet battery production line

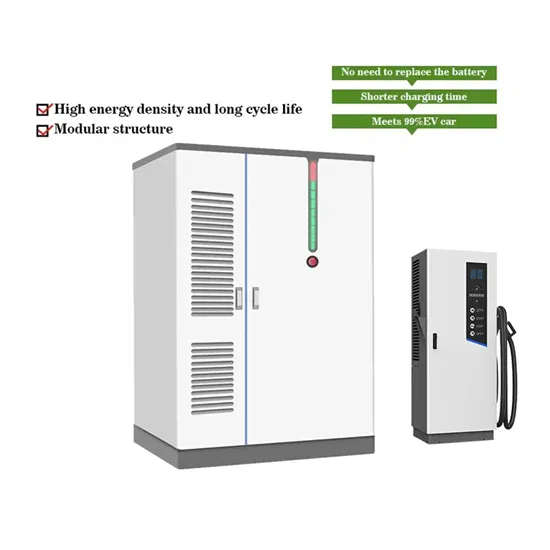

ENERGY STORAGE SYSTEM Lithium-ion battery system for ABB ter, production line or any other type of critical process, lithium-ion battery solutions provide peace of mind and the

Battery cabinet production line operation cost analysis

Battery cabinet production line investment Towards the lithium-ion battery production network: Thinking A single battery for a Tesla Model Y, for example, comprises 4416 cells, and a

Design of cubic battery cabinet production line

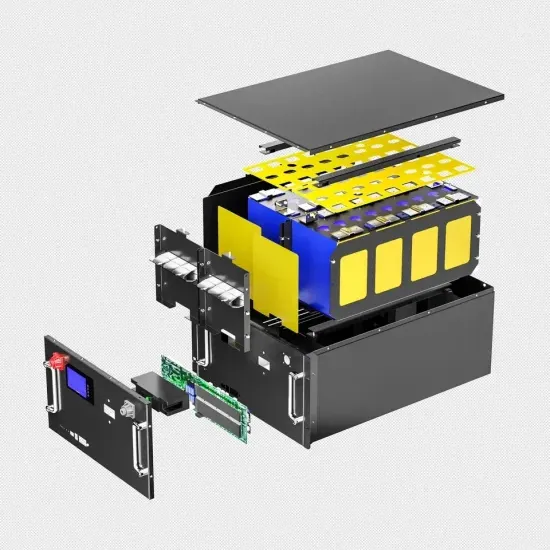

in phases: production, assembly, and packaging. The pack is a complex system comprising battery packs, shunts, soft connections, protective boards, outer packaging, output

Lion Energy building out large energy storage

Oct 14, 2024 · Battery manufacturer Lion Energy is developing a manufacturing line at its Utah facility for battery rack modules (BRM) and large energy

Lithium-ion Battery Module and Pack Production

Apr 12, 2024 · The production line starts with the battery cell handling equipment, which is responsible for the initial handling and testing of the battery cells. At

Battery cabinet production design drawings

Unified Power offers a complete line of battery cabinets for both UPS and Telecom Applications. These cabinets can be configured to match OEM cabinets and offer a competitive option for

Optimizing Lithium-Ion Battery Pack Line

Oct 22, 2024 · Precise Control of Production Rate: Modern battery pack production requires a different approach to maintain a high and efficient

Your Paper''s Title Starts Here:

Apr 27, 2025 · As the application of new technology in the field of industrial automation, industrial robotics technology has attracted much attention and has been applied in more and more

What are the Stages of Battery Manufacturing?

Feb 20, 2025 · Investing in a battery production line that incorporates advanced battery manufacturing equipment and battery machines enables businesses to

Learning lean: Rhythm of production and the pace of

Jan 13, 2021 · We propose a theory of the relation between rhythm and learning in lean implementation. Research implications: The hitherto unexplored relation between production

What is a battery module production line?

Nov 1, 2024 · 4. Unique advantages of automated production lines Automated production lines have the following significant advantages in battery module manufacturing: 1. Production

Battery Manufacturing Basics from CATL''s Cell

Jun 13, 2021 · Although much of the details of the manufacturing process are proprietary, we have identified and outlined the 3 main production stages and

Production Line Guide | CHISAGE Battery Pack

Sep 14, 2023 · The production process for Chisage ESS Battery Packs consists of eight main steps: cell sorting, module stacking, code pasting and scanning,

(PDF) BATTERY MODULE AND PACK ASSEMBLY

Feb 6, 2019 · Our second brochure on the subject "Assembly process of a battery module and battery pack" deals with both battery module assembly and

4680 battery cabinet production line

4680 battery cabinet production line Who makes 4680 batteries? The South Korean supplier will be the first global battery maker to mass-produce 4680 batteries. The LGES Ochangfactory''s

Optimize Battery Assembly Line with Design and

Aug 14, 2025 · In this blog, we''ll explore how smart design and automation can help you break through the bottleneck. You''ll discover how effective mechanical design and controls

Energy storage cabinet assembly production line process

Energy storage cabinet assembly production line process What is the production process for chisage ESS battery packs? The production process for Chisage ESS Battery Packs consists

Container energy storage cabinet production line

Aug 6, 2021 · ABB''s containerized energy storage solution is a complete,self-contained battery solution for a large-scale marine energy storage. The batteries and all control,interface,and

Apr 21, 2025 · TAICO lithium battery production process analysis: fully automated production lines, stringent testing and industry-leading advantages In the lithium battery industry, the

battery production line

Mar 28, 2023 · In this article, we will discuss the equipment used in each stage, the advantages of a battery production line, and some important considerations for ensuring successful

Battery capacity cabinet production

How many battery factories will be built in 2022? In total, at least 120 to 150 new battery factories will need to be built between now and 2030 globally. In line with the surging demand for Li-ion

Battery module production | KUKA AG

KUKA supplies fully automated production line for battery modules to ElringKlinger, systems partner to the automotive industry.

CABINET PRODUCTION LINE | Download

Download scientific diagram | CABINET PRODUCTION LINE from publication: Smart Agent-Based Priority Dispatching Rules for Job Shop Scheduling in a

ENERGY STORAGE CABINET PRODUCTION LINE

Battery production for energy storage power stations A battery energy storage system (BESS), battery storage power station, battery energy grid storage (BEGS) or battery grid storage is a

Production rhythm

Dec 2, 2024 · Production rhythm involves balanced, consistent with the schedule, manufacture and transfer of products and equally repetitive, and coordinated work stations in the company.

Battery Production Line

Oct 9, 2024 · These production lines are critical in meeting the growing demand for batteries in applications such as electric vehicles (EVs), consumer electronics, renewable energy storage,

Battery cabinet production cost accounting

Further declines in battery cost and critical mineral reliance might come from sodium-ion batteries, which can be produced using similar production lines to those used for lithium-ion batteries.

Photovoltaic battery cabinet production line

Production line of Silent Power Off-Grid Cabinets Silent Power cabinet is the first solar photovoltaic cabinet that is delivered fully assembled with all the protection and monitoring

Production Line Guide | CHISAGE Battery Pack

Sep 14, 2023 · Production Line Overview Chisage ESS has been in the field of solar battery for many years and is committed to producing high-quality energy

Optimal line configurations for agile production systems for battery

Jan 1, 2023 · Production plan 1 can be processed fastest on line 1, production plan 2 on line 2 and production plan 3 on line 3. It could thus be shown that, depending on the requirements of the

Tertron: Your Partner in Advanced Battery

Choose TERTRON''s automated battery production lines, featuring precision assembly, integrated quality control, and scalability for lithium-ion and other

The production of lithium-ion (Li-ion) batteries is a complex process that involves several key steps, each crucial for ensuring the final battery''''s quality and performance. In this article, we

Power Battery: the Application of AGV and AMR

In the application scenario of AGV/AMR in the power battery production line, enterprises pay more attention to the accuracy of AGV/AMR positioning, the

Understanding Lithium Ion Battery Manufacture

Jun 28, 2024 · Production Line The production line for lithium battery packs is a highly integrated system designed to streamline the manufacturing process

6 FAQs about [Battery cabinet production line production rhythm]

How does a battery production line work?

First, the battery cells are put into the production line manually, then the production line equipment automatically scans the battery cells, and at the same time carries out the internal resistance and voltage test, in order to screen out the battery cells with qualified quality.

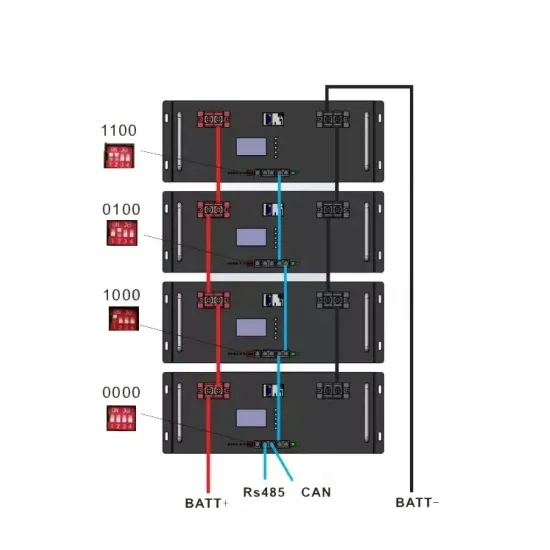

What is a typical production line for battery packs?

A typical production line for battery packs serves two main purposes: transmission and testing. In the industry, it is common to use semi-automatic assembly lines for pack production. These lines handle tasks such as launching, offline operations, testing, in-plant transmission, and packaging.

What is a lithium-ion battery module & pack production line?

The lithium-ion battery module and pack production line is a complex system consisting of multiple major units and associated equipment that work in concert to achieve high quality lithium-ion module and pack production.

What is a lithium battery production line?

These lines handle tasks such as launching, offline operations, testing, in-plant transmission, and packaging. The processes involved in a lithium battery pack production line are relatively simple, including feeding, attaching brackets, welding, and conducting thorough testing, among other steps.

Why should you choose a lithium-ion battery module & pack line?

The whole system has no leakage of electricity, water, liquid or gas, which ensures the safety and stability of the production process. The lithium-ion battery module and pack line is a key component in the field of modern battery technology. Its high degree of automation and rigorous process flow ensure high quality and efficiency in production.

What is the packaging and Assembly of lithium-ion battery packs?

The packaging and assembly of lithium-ion battery packs are crucial in the field of energy storage and have a significant impact on applications like electric vehicles and electronics. The pack line process consists of three main phases: production, assembly, and packaging.

Industry Information

- How many volts does a 30 watt solar panel have

- Bandar Seri Begawan Energy Storage Battery Customization

- Russia St Petersburg courtyard photovoltaic glass supplier

- How to store energy in the power industry

- Battery cabinet equipment price

- Small container silent generator

- Wind energy plus photovoltaic energy storage

- Austria EKlfp energy storage battery

- Do photovoltaic solar panels emit radiation

- How to modify the battery cabinet for lead-acid batteries

- Which is more important single lithium battery or pack

- Monocrystalline Solar Panel Photovoltaic

- Can 10 kWh of energy storage power be used

- Can t the battery power the inverter

- Cooling system energy storage cooling

- United Arab Emirates special energy storage battery

- Energy storage container battery ems

- Photovoltaic home energy storage cabin

- Charging station energy storage unit price

- Which companies manufacture energy storage battery container equipment

- Polish energy storage photovoltaic combiner box merchants

- Stockholm Power Base Station Tender

- Kathmandu Green New Energy Photovoltaic Site

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.