Fabricating Different Types of Photovoltaic Cells

Jun 2, 2021 · The manufacture of crystalline silicon modules involves fabricating silicon wafers, transforming the wafers into cells, and assembling cells into

The solar energy industry has witnessed remarkable

Mar 1, 2025 · What Are Solar Wafers? A solar wafer, also known as a silicon wafer, is a thin slice of crystalline silicon that serves as the foundation for fabricating integrated circuits in

Status and perspectives of crystalline silicon photovoltaics in

Mar 7, 2022 · Crystalline silicon solar cells are today''s main photovoltaic technology, enabling the production of electricity with minimal carbon emissions and at an unprecedented low cost. This

Solar Cell Production: from silicon wafer to cell

4 days ago · Cell Fabrication – Silicon wafers are then fabricated into photovoltaic cells. The first step is chemical texturing of the wafer surface, which removes

Trends of Solar Silicon Wafer Size and Thickness

Mar 31, 2025 · The solar industry has witnessed a recent dynamic transformation in wafer size and wafer thickness, driven by advancements in cell

Stress Analysis of Silicon Wafer-Based Photovoltaic Modules Under IEC

Jan 1, 2013 · Snow loading poses a significant problem to the integrity of photovoltaic (PV) modules. The weight of accumulated snow exerted on the PV modules can cause breakage of

Solar Wafers: The Building Blocks of Photovoltaic

Apr 5, 2024 · Explore the essence of solar cell technology with solar wafers, the critical component in driving India''s photovoltaic innovation.

Crystalline Silicon Terrestrial Photovoltaic Cells

4 days ago · Executive Summary and standard that applies to photovoltaic (PV) cells. Many PV module manufacturers depend on third party solar cell manufacturers for their supply of silicon

High-efficiency Module,Longi solar module

12 hours ago · LONGi High-efficiency solar Module, widely adopting PERC solar cells technology, Half-cut Module Technology and Bifacial PV

Fab & analysis of silicon wafer-based PV modules

May 21, 2024 · Introduction In conventional silicon wafer-based PV technology, solar cells are connected in series and encapsulated into PV modules. The interconnection increases the

Review of c-Si PV module recycling and

Jan 21, 2025 · Abstract As solar energy emerges as a pivotal renewable energy source, the environmental challenge of end-of-life photovoltaic (PV) module

Solar Panel Manufacturing Process: Step-by-Step Guide

Apr 12, 2025 · Complete solar panel manufacturing process – from raw materials to a fully functional solar panel. Learn how solar panels are made in a solar manufacturing plant,

Crystalline Silicon Module

Crystalline silicon or silicon wafer is the dominant technology for manufacturing of PV solar cells. The monocrystalline silicon and polycrystalline silicon are popular for high efficiency solar cells.

Crystalline Silicon Solar Cell and Module Technology

Jan 1, 2018 · The silicon energy bandgap determines the ultimate efficiency of PV cells made from c-Si; this value is 29.4%. As already explained in Section 8.4.2, c-Si solar cells have to be

Solar Cells and Modules

Polycrystalline Silicon Photovoltaic (PV) Cells Polycrystalline or multi crystalline silicon PV cells are made from cast square ingots — large blocks of molten

Solar Wafers for PV Module Manufacturers

Aug 18, 2025 · We offer a complete range of silicon solar wafers for photovoltaic cell manufacturers, module producers, and PV suppliers in over 50 countries.

Wafer-Based Solar Cell

Most PV technologies that have been deployed at a commercial level have been produced using silicon, with wafer-based crystalline silicon (c-Si) currently the most popular solar cells

What Are Wafer-Based Solar Cells?

Aug 19, 2025 · Photovoltaic cells or solar cells convert light energy into electrical energy using the photovoltaic effect. Most of these are silicon cells, ranging

PV-Manufacturing – The free online resource

Silicon photovoltaic modules comprise ~90% of the photovoltaic modules manufactured and sold worldwide. This online textbook provides an

What is Wafer in PV?

Nov 17, 2023 · A solar wafer is a semiconductor working as a substrate for microeconomic devices to fabricate integrated circuits in photovoltaics (PV) to

Wafering – PV-Manufacturing

6 days ago · In addition, the transition from slurry to diamond wire sawing also inspired some companies to investigate more advanced surface texturing

Driving Forces in the 2024 PV Industry: Wafer Size Evolution

Sep 24, 2024 · With the arrival of 2024, the PV industry is undergoing unprecedented changes, with the evolution of wafer sizes and technological innovations becoming key driving forces.

Manufacturing of Silicon Solar Cells and Modules

Jun 13, 2023 · To get from cell making to module making requires proper preparation of pristine wafers to be physically and electrically connected in series to achieve the rated output of a PV

The solar cell wafering process

May 21, 2024 · AbstrAct The process of wafering silicon bricks represents about 22% of the entire production cost of crystalline silicon solar cells. In this paper, the basic principles and

How Solar Silicon Wafers Are Made into Cells

Jan 9, 2024 · How Solar Silicon Wafers Are Made into Cells The process of transforming solar silicon wafers into cells involves several meticulous steps,

Investigation of the short-circuit current increase for PV modules

Feb 1, 2015 · It is well established that using halved silicon wafer solar cells in a photovoltaic (PV) module is an efficient way to reduce cell-to-module resistiv

Silicon Solar Cell

Silicon ingots of mono-crystalline crystal or solar-grade poly-crystalline silicon are then sliced by band or wire saw into mono-crystalline and poly-crystalline wafers into 156 × 156 mm 2 size

What Is a Silicon Wafer for Solar Cells?

Silicon wafer-based photovoltaic cells are the essential building blocks of modern solar technology. EcoFlow''s rigid, flexible, and portable solar panels use the highest quality

How Solar Silicon Wafers Are Made into Cells

Jan 9, 2024 · How Solar Silicon Wafers Are Made into Cells. The process of transforming solar silicon wafers into cells involves several meticulous steps,

Eco-friendly method for reclaimed silicon wafer from

A sustainable method for reclaiming silicon (Si) wafer from an end-of-life photovoltaic module is examined in this paper. A thermal process was employed to remove ethylene vinyl acetate

A method to recycle silicon wafer from end-of-life photovoltaic module

Apr 1, 2017 · Silicon has a special role in the PV supply chain, namely as the raw material for poly-silicon; the material for the ingot process; and the wafer of solar cells. The price of the Si

Photovoltaic recycling: enhancing silicon wafer recovery

Apr 30, 2024 · The rapid proliferation of photovoltaic (PV) modules globally has led to a significant increase in solar waste production, projected to reach 60–78 million tonnes by 2050. To

6 FAQs about [Silicon wafer cell photovoltaic module]

What are silicon wafer-based photovoltaic cells?

Silicon wafer-based photovoltaic cells are the essential building blocks of modern solar technology. EcoFlow’s rigid, flexible, and portable solar panels use the highest quality monocrystalline silicon solar cells, offering industry-leading efficiency for residential on-grid and off-grid applications.

What is silicon wafer based PV technology?

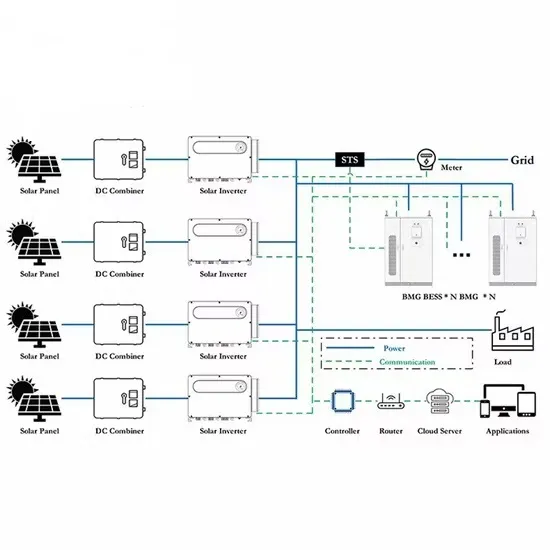

In silicon wafer-based PV technology, solar cells are connected in series and encapsulated into PV modules. The interconnection increases the power and voltage, while the encapsulation provides environmental protection for the solar cells.

Which solar panels use wafer based solar cells?

Both polycrystalline and monocrystalline solar panels use wafer-based silicon solar cells. The only alternatives to wafer-based solar cells that are commercially available are low-efficiency thin-film cells. Silicon wafer-based solar cells produce far more electricity from available sunlight than thin-film solar cells.

How are solar silicon wafers made into cells?

How Solar Silicon Wafers Are Made into Cells The process of transforming solar silicon wafers into cells involves several meticulous steps, including wafer slicing, doping, and passivation, which culminate in the creation of functional photovoltaic cells.

Do thin-film solar cells use silicon wafers?

Thin-film solar cells don’t use silicon wafers but are highly inefficient and rarely used. Silicon wafer-based photovoltaic cells are the essential building blocks of modern solar technology.

Are silicon wafer-based solar cells a good investment?

Silicon (Si) wafer-based solar cells currently account for about 95% of the photovoltaic (PV) production and remain as one of the most crucial technologies in renewable energy. Over the last four decades, solar PV systems have seen a staggering cost reduction due to much reduced manufacturing costs and higher device efficiencies.

Industry Information

- Guinea-Bissau best-selling photovoltaic panel manufacturers

- Huawei Micro Inverter Assembly

- Iraq container generator manufacturers

- Do you have a 100kw inverter

- Energy storage power cabinet manufacturers

- Guinea Solar Power System Manufacturer

- Home Base Station Power Supply

- What does outdoor power storage capacity mean

- Are silicon wafers used for power generation or energy storage

- Accra Single Energy Storage Project

- Tokyo Energy Storage Vehicle Price

- French Photovoltaic Glass Project

- Which lithium iron phosphate battery energy storage container is better

- New energy vehicles require outdoor power supply

- Recommended brand of portable power bank in El Salvador

- Cambodia explodes communication base station battery

- Does a photovoltaic inverter not require a battery

- What is the hybrid energy power supply for communication base stations called

- Portable energy storage product production in Romania

- Micro inverter support

- Canberra communication base station inverter grid-connected manufacturer

- Photovoltaic inverter belongs to photovoltaic module

- North Macedonia photovoltaic off-grid power generation system

Commercial & Industrial Solar Storage Market Growth

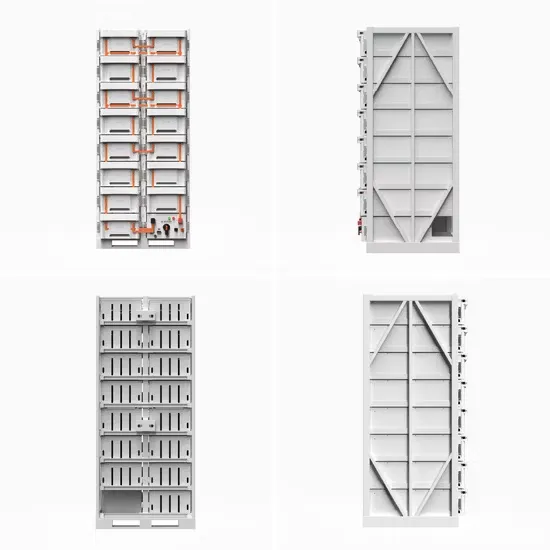

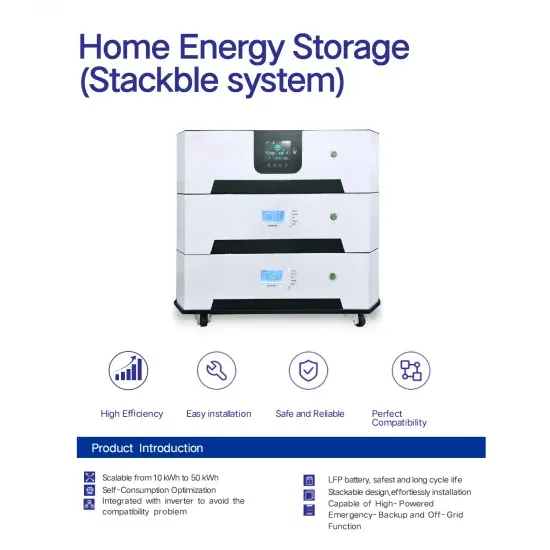

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

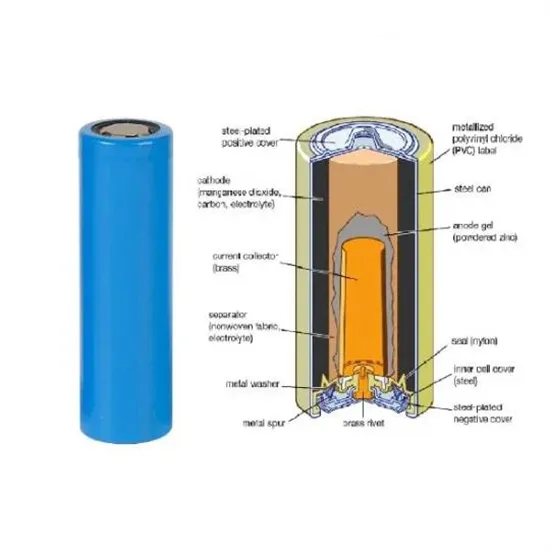

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.