National Blueprint for Lithium Batteries 2021-2030

Jul 1, 2024 · Lithium-based batteries power our daily lives from consumer electronics to national defense. They enable electrification of the transportation sector and provide stationary grid

The Manufacturing Process of Lithium Batteries Explained

Sep 18, 2024 · Lithium battery manufacturing encompasses a range of processes designed to produce efficient and reliable energy storage solutions. The demand for lithium batteries has

Lithium-Ion Battery Pack Manufacturing Process

Jun 4, 2025 · Discover how lithium-ion battery packs are made—sorting, welding, assembly, BMS integration, and testing—to deliver reliable power for EVs,

The new version of the lithium-ion battery industry standard

"Lithium-ion battery industry standard conditions (2021)" proposes to guide companies to reduce manufacturing projects that simply expand production capacity, strengthen technological

Current and future lithium-ion battery manufacturing

Apr 23, 2021 · LIB industry has established the manufacturing method for consumer electronic batteries initially and most of the mature technologies have been transferred to current state-of

What are the lithium battery standards?

Dec 4, 2021 · What are the lithium battery standards? There are a number of national and international organizations responsible for setting and enforcing

Evaluation of the safety standards system of power batteries

Nov 1, 2023 · China''s existing battery safety standards mainly focus on post-production battery testing, namely the mechanical abuse, electrical abuse, thermal abuse, and environmental

Battery Certification 2025: Types, Costs and

Aug 14, 2024 · Battery certification plays a crucial role in ensuring the safety and performance of battery products across various industries. In this guide, we''ll

Lithium-Ion Battery Pack Manufacturing Process

Jun 4, 2025 · Each phase plays a critical role in ensuring the performance, safety, and reliability of the battery module. With proper attention to quality and

TfiTh 11 Lflffftfl Ifi Bffff Rffflfi

Nov 26, 2024 · TfiTh 11 Lflffftfl Ifi Bffff Rffflfi Top 11 Lithium Ion Battery Regulations Lithium ion batteries have received increased scrutiny due to a number of high-profile events that have

"National Lithium Battery Industry Standard System

Nov 21, 2024 · It is proposed that,2026 new national standards and industry standards100 above, the standard system leading the high-quality development of the lithium battery industry is

Lithium Ion Battery Manufacturing Process

Aug 17, 2025 · The production of lithium-ion batteries requires extensive procedures. This guide details lithium ion battery manufacturing process.

PRODUCTION OF LITHIUM-ION BATTERY CELL

Feb 7, 2024 · The volume of lithium-ion batteries (LIB) sold will increase significantly in the coming years due to the growing number of electric vehicles on the market, which means that the

Custom Lithium Battery Pack Manufacturing

Key Takeaway: Manufacturing custom lithium-ion battery packs requires precise engineering, quality control, and safety standards. The process involves

PRODUCTION OF LITHIUM-ION BATTERY CELL

Feb 7, 2024 · The ''Production Process of a Lithium-Ion Battery Cell'' guide pro-vides a comprehensive overview of the production of different battery cell formats, from electrode

China Issues Mandatory Industry Standard for Lithium-Ion Battery

On May 13, 2025, China''s Ministry of Emergency Management has issued a new mandatory industry standard, AQ 7017-2025, titled " Safety Code for Lithium-Ion Battery Production."

The Manufacturing Process of Lithium Batteries

The lithium battery manufacturing industry is dominated by countries like China, Japan, and South Korea, which are major manufacturers and suppliers of

China Adopts New Li-Ion Battery Pack

May 23, 2024 · China has announced that the country is instituting new technical standards for the manufacture of lithium-ion batteries. The new technical

The Production Process of Cylindrical Lithium

Mar 8, 2025 · Uncover the detailed production process of cylindrical lithium - battery packs. Learn about key steps like cell selection, grouping, module assembly, BMS integration, and more.

Lithium Battery Testing & Standards | Ensure

Feb 22, 2025 · Without testing, lithium batteries could become dangerous in daily use and transportation. In this post, you''ll learn why lithium battery testing

CellPac PLUS

5 days ago · In the POWER division, VARTA Storage develops rechargeable standard and customized lithium-ion battery packs. Regardless of the technology or the complexity of the

General overview on test standards for Li-ion batteries,

Nov 7, 2017 · Electric and Hybrid Vehicle Propulsion Battery System Safety Standard - Lithium-based Rechargeable Cells.

Lithium-Ion Battery Manufacturing: Industrial

Nov 15, 2023 · In this review paper, we have provided an in-depth understanding of lithium-ion battery manufacturing in a chemistry-neutral approach starting

Understanding Global Lithium Battery Standards and

Feb 11, 2025 · They have specific standards that ensure the safety of lithium-ion cells in consumer electronics (UL 1642), apply to battery pack durability (UL 2054), apply to EV battery safety

Lithium-Ion Battery Manufacturing: Industrial

Nov 15, 2023 · Developments in different battery chemistries and cell formats play a vital role in the final performance of the batteries found in the market.

IEC publishes standard on battery safety and

May 25, 2022 · Industry, with its unique power requirements, uses batteries that focus on durability and reliability. IEC 62619 specifies requirements and tests

China revises guidelines for lithium-ion battery industry

Jun 19, 2024 · China''s Ministry of Industry and Information Technology on Wednesday unveiled revised guidelines for the lithium-ion battery industry to further strengthen standardized

Standards specific to the battery manufacturing industry

The strict standards and regulations of the battery manufacturing industry guarantee safety, performance and durability. Find out more about production, recycling, traceability and

Battery manufacturing and technology standards

Jul 28, 2021 · Table 1 – Current standards of relevance for battery manufacture Table 2 – Prioritization of immediate standards needs, and gaps identified Table 3 – Prioritization of

Battery Production Flyer: Lithion Ion Cell Production

Feb 7, 2024 · The chair "Production Engineering of E-Mobility Components" (PEM) of RWTH Aachen University has been active in the field of lithium-ion battery production technology for

Lithium-ion battery packs | VARTA AG

Aug 18, 2025 · In the Power Pack Solutions division, VARTA develops rechargeable standard and customized lithium-ion battery packs. Regardless of the technology or the complexity of the

Battery Manufacturing Basics from CATL''s Cell

Jun 13, 2021 · The industrial production of lithium-ion batteries usually involves 50+ individual processes. These processes can be split into three stages:

How Policy Shifts Impact Lithium Battery Production and

Apr 4, 2025 · Delve into how global policy shifts impact lithium-ion battery innovation—including climate agreements, trade policies, and energy policies.

Industry Information

- Photovoltaic power generation module inverter

- High temperature photovoltaic panel voltage range

- Solid state breaker in China in Us

- Portable 1 5 degree power supply

- Power distribution cabinet required for energy storage power station

- South African energy storage vehicle prices

- UHPC photovoltaic energy storage cabinet

- Indian photovoltaic panel manufacturer

- Container assembly generator case

- Copenhagen Solar Cell Energy Storage Company

- What are the suppliers of outdoor communication battery cabinets in Egypt

- Containerized energy storage battery base station

- Ljubljana photovoltaic curtain wall glass manufacturer

- Kabul wind solar and energy storage companies involved

- Indonesian Bay Port Energy Storage Project

- Congo Garden Container Energy Storage

- Solar power storage solutions in Jakarta

- Actual capacity and energy storage capacity of mobile power bank

- Sukhumi wind solar and energy storage power generation system

- What are the inverters for Irish communication base stations

- Outdoor power supply external battery

- 1000w photovoltaic panel size

- Huawei builds energy storage system in Bogota

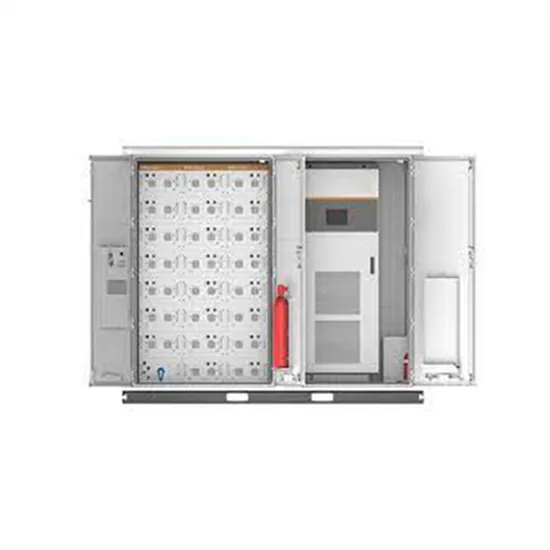

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

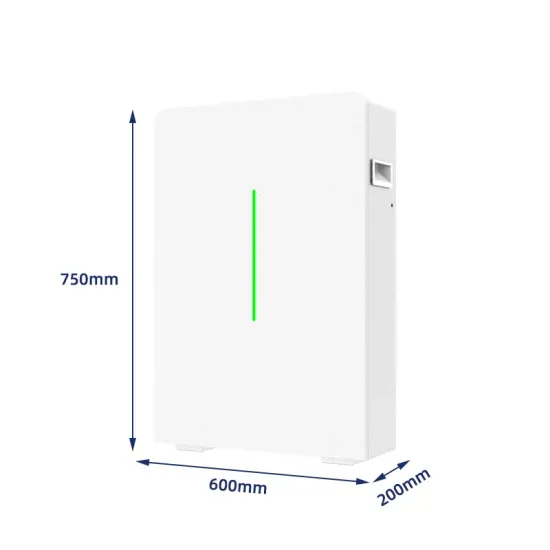

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.