Time-resolved characterization of toxic and flammable gases

Apr 1, 2025 · Large-scale battery failures can lead to explosion and toxicity hazards. Mitigation of battery hazards requires accurate data of battery flammable and toxic gas composition and

Complete Guide to Cylindrical Cell

Apr 7, 2024 · Cylindrical lithium battery cells are generally used in power batteries, such as the typical 21700 battery cells carried in the Tesla Model 3,

Design, Properties, and Manufacturing of Cylindrical Li

Jul 7, 2023 · In the last 3 years, cylindrical cells have gained strong relevance and popularity among automotive manufacturers, mainly driven by innovative cell designs, such as the Tesla

Thermal evaluation of lithium-ion batteries: Defining the cylindrical

Oct 1, 2022 · Managing temperatures of lithium-ion cells in battery packs is crucial to ensuring their safe operation. However, thermal information provided on typi

How uniform particle size of NMC90 boosts lithium ion

Feb 7, 2024 · How uniform particle size of NMC90 boosts lithium ion mobility for faster charging and discharging in a cylindrical lithium ion battery cell†

Stress analysis of a cylindrical composition

May 20, 2016 · A novel cylindrical composition-gradient electrode is considered to be one of most potential structures in lithium-ion battery. To investigate the

Comparison between 18650 Lithium-ion Cells of

Nov 14, 2023 · Figure 1 illustrated the cylindrical lithium-ion cells, 18650, considered in this study (a) Lithium Nickel Cobalt Aluminium Oxide (NCA), (b) Lithium Titanate Oxide (LTO) and (c)

Practical 4.7 V solid-state 18650 cylindrical lithium metal batteries

Jan 17, 2025 · Significantly, our LHCE-GPE allows for the operation of practical solid-state 18650 cylindrical LMBs at 4.7 V and industrial Li-ion batteries at 4.6 V, achieving high energy

The Advantages and Applications of Cylindrical Lithium Batteries

Dec 16, 2023 · In our rapidly evolving technological landscape, the use of batteries has become ubiquitous, powering countless devices and systems that make our lives easier and more

Layered lithium

Mar 15, 2025 · Layered lithium- and manganese-rich oxide (LMRO or LMR-NMC) cathodes have emerged as promising candidates for next-generation lithium-ion batteries due to their unique

Analysis of electrolyte degradation products in cylindrical

Aug 4, 2025 · The impact of battery electric vehicles (BEVs) using lithium-ion cells (LICs) as energy storage systems is increasing and topics as cell performance and lifetime of the cell

Stress analysis in cylindrical composition

Jul 26, 2017 · In recent years, the composition-gradient electrode material has been verified to be one of the most promising materials in lithium-ion battery.

Mechano-Electrochemical Analysis in Cylindrical Composition

Mar 8, 2019 · Composition-gradient electrode material (CGEM) is one of the most promising materials in lithium-ion battery, and this paper studies its performance from the stress analysis.

Homogeneous constitutive relationship of cylindrical lithium

Jul 1, 2025 · In this study, we design a loading apparatus capable of precisely measuring the relationship between the loading distance and the contact area between the battery and the

the structure and composition of 18650

Download scientific diagram | the structure and composition of 18650 cylindrical batteries. from publication: Comparative study of chemical discharge strategy

Comparison of Different Types of Electric Vehicle

The 3 Different Types of Car Batteries There are three types of EV battery cells for electric vehicles: cylindrical, prismatic, and pouch. All of these batteries are

3 Different Shapes Lithium Battery Structures

Nov 11, 2019 · At present, there are three main types of mainstream lithium battery structures, namely, cylindrical, rectangular and pouch cells. Different

The structure of a cylindrical lithium-ion battery

This survey is to review the advancement recorded so far in the lithium-ion battery recycling technologies in compliance with environmental laws. Amongst many

BYD vs. Tesla: Who Wins the EV Battery Battle?

Apr 4, 2025 · Researchers broke down BYD''s LFP Blade battery and Tesla''s cylindrical cells. This comprehensive comparison of the industry''s two leading

A Comprehensive Guide to Cylindrical Lithium

Jul 31, 2025 · Cylindrical lithium-ion battery cells are a type of rechargeable battery commonly used in a wide range of electronic devices, electric vehicles,

Design, Properties, and Manufacturing of

Jun 3, 2023 · This paper investigates 19 Li-ion cylindrical battery cells from four cell manufacturers in four formats (18650, 20700, 21700, and 4680). We aim

Introduction of the Cylindrical Lithium Ion Battery

Apr 13, 2023 · The structure of a typical cylindrical lithium ion battery includes: shell, cap, positive electrode, negative electrode, separator, electrolyte, PTC element, gasket, safety valve, etc.

Lithium-ion Battery Cells and Chemistries: The

Aug 28, 2022 · Lithium-ion Cell Formats The lithium battery pack, often known as the assembly of different components, contains individual cells. These cells

Cylindrical lithium battery classification and

May 17, 2023 · Cylindrical lithium-ion cells are usually represented by five digits unting from the left,the first and second digits refer to the diameter of

Comprehensive knowledge of 18650 batteries

Comprehensive knowledge of 18650 batteries The 18650 Battery is one of the most common battery models, but it actually has many classifications. If you don''t understand these details, it

A detailed computational model for cylindrical lithium-ion batteries

Feb 15, 2019 · A detailed computational model for cylindrical lithium-ion batteries under mechanical loading: From cell deformation to short-circuit onset

Everything about Cylindrical Batteries, the Power

May 29, 2024 · The importance of cylindrical batteries is only growing because they are used widely from small electronic devices to EVs. In line with the

How cylindrical lithium ion battery cells are

This is what the cylindrical cells of lithium ion batteries look like, containing: anode, cathode, separator and electrolyte

Experimental and simulation study of direct current

Oct 10, 2023 · Understanding the contribution of internal direct current resistance (DCR) is crucial to the design and optimization of lithium-ion batteries (LIBs). However, the complex dynamic

Lithium-ion cell knowledge comprehensive

This is a comprehensive article about lithium-ion battery cells, including the basic knowledge of lithium battery cells, material knowledge, process knowledge,

NMC Composition

Nov 15, 2023 · NMC Composition can be difficult to understand at first and so here is a walk through the compositions and what they actually mean.

Contrasting a BYD Blade prismatic cell and Tesla 4680 cylindrical

Mar 19, 2025 · Summary In order to provide design guidance for the development of next-generation batteries, this article presents a teardown analysis of two commercial lithium-ion

Lithium Thionyl Chloride (Li-SOCl2) Batteries: An

Mar 17, 2025 · Robust Performance in Extreme Conditions The wide operating temperature range and robust construction make Li-SOCl2 batteries suitable

The Science of Cylindrical Cells: Understanding

Oct 11, 2024 · Cylindrical cells have become an integral part of the energy storage industry, with a promising future ahead. These cells, also known as

The chemical composition of individual lithium

Download scientific diagram | The chemical composition of individual lithium-ion batteries, based on [12]. from publication: The Necessity of Recycling of

A Structure of Cylindrical Lithium-ion Batteries

Jul 14, 2016 · Figure 3 demonstrates a structure of a cylindrical lithium-ion battery cell. The components in the cylindrical cell can be classified into three major groups: a jellyroll, current

Design, Properties, and Manufacturing of Cylindrical Li-Ion

Jun 3, 2023 · This paper investigates 19 Li-ion cylindrical battery cells from four cell manufacturers in four formats (18650, 20700, 21700, and 4680). We aim to systematically capture the design

Stress analysis in cylindrical composition-gradient

Sep 30, 2023 · In recent years, the composition-gradient electrode material has been verified to be one of the most promising materials in lithium-ion battery. To investigate diffusion-induced

6 FAQs about [Cylindrical lithium battery composition]

What is a cylindrical lithium battery cell?

Cylindrical lithium battery cells are generally used in power batteries, such as the typical 21700 battery cells carried in the Tesla Model 3, which once made 21700 popular in the battery cell market. However, cylindrical cells are not the only advantages; their shortcomings are also obvious.

How many Li-ion cylindrical battery cells are there?

This paper investigates 19 Li-ion cylindrical battery cells from four cell manufacturers in four formats (18650, 20700, 21700, and 4680). We aim to systematically capture the design features, such as tab design and quality parameters, such as manufacturing tolerances and generically describe cylindrical cells.

How do you identify a cylindrical lithium-ion battery?

For instance, “65” represents a height of 65mm. Fifth Digit: The fifth digit indicates the cylindrical shape of the cell. Typically, it’s “0” for cylindrical cells. By following this naming convention, we can easily identify the size and shape of cylindrical lithium-ion battery cells.

What are cylindrical lithium-ion batteries used for?

With the cylindrical cell format, the batteries can be applied to many applications, for example, power tools, laptops, portable electronic devices and electric vehicles. Figure 2 shows cylindrical lithium-ion batteries in a laptop and a power tool.

What is a cylindrical battery?

The following is a common cylindrical cell structure; see the image below for details: Ordinary cylindrical lithium-ion batteries consist of a casing, a cap, a positive electrode, a negative electrode, a separator, and an electrolyte. Generally, the battery casing is the battery’s negative electrode, and the cap is the battery’s positive electrode.

Why are cylindrical battery cells so popular?

In the last 3 years, cylindrical cells have gained strong relevance and popularity among automotive manufacturers, mainly driven by innovative cell designs, such as the Tesla tabless design. This paper investigates 19 Li-ion cylindrical battery cells from four cell manufacturers in four formats (18650, 20700, 21700, and 4680).

Industry Information

- Containerized photovoltaic mobile integrated machine

- Maintenance of photovoltaic power generation for grid-connected inverter of communication base station

- Photovoltaic glass factory for export in New York USA

- Outdoor photovoltaic battery battery cabinet 36KW

- How much does the UPS uninterruptible power supply cost for the Berlin power distribution room

- 220mA inverter

- Muscat lithium battery PACK

- Male energy storage temperature control system equipment

- 8000w60v smart inverter

- Advantages and disadvantages of discharge energy storage gel batteries

- New Zealand energy storage project approved

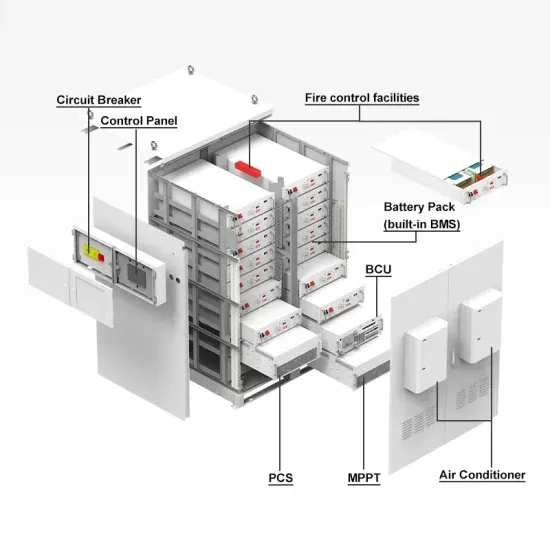

- Energy Storage Container Decomposition

- High quality wholesale switchgear breaker company

- Freetown cylindrical lithium battery manufacturer

- Cheap wholesale battery and storage for sale

- Haiti Outdoor Power Plant

- Rooftop solar panels

- Outdoor portable mobile charging source

- 120A Battery Inverter

- Differences between energy storage batteries and energy storage power stations

- Guinea special photovoltaic folding container wholesale

- Aluminum cables can be used for wind and solar hybrid communication base stations

- Cape Verde inverter price

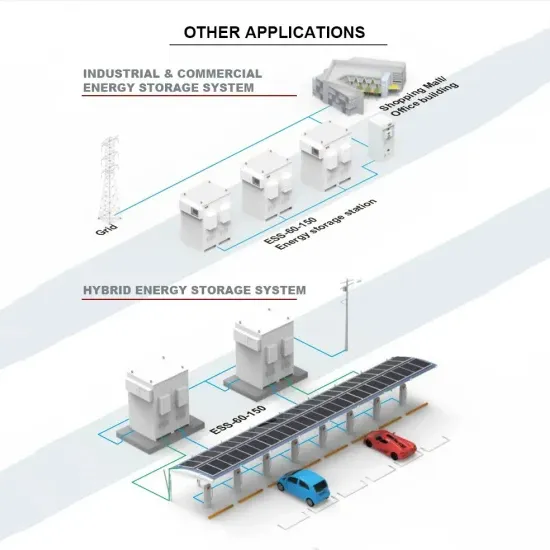

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.