Selection and calculation of dclink capacitor in

Dc-link capacitors are considered as one of the sensitive parts of the grid connected photovoltaic systems and needs effort to design a reliable and optimal size capacitor as its reliability is

Explanation of Inverter DC Capacitance and Inrush Current

Dec 14, 2023 · All modern power inverters have a large capacitor bank at their DC input terminals to help provide smooth power conversion from DC to an AC sine wave and back to DC when

Reveal the function and type of inverter capacitor –

Jan 17, 2024 · Voltage regulation: Inverter capacitor assist in maintaining a consistent voltage level, preventing fluctuations that could potentially harm connected devices. Energy storage:

Voltage Inverter : Circuit, Working and Its

Mar 30, 2019 · Most inverters are of the variable voltage, variable frequency design. They consist of a converter section, a bus capacitor section and an

Has anyone thought of using capacitors between the inverter and

Aug 18, 2025 · and AFIK, they cannot be stacked in series to get higher voltage than 12V. And the "specs" on that page have no voltage range, internal resistance or any electronic spec.

DC-Link design tips: how to choose capacitors

Mar 24, 2021 · DC-link capacitors are used in order to provide more stable DC voltage and limit fluctuations, as the inverter demands heavy current

What capacitors are used in photovoltaic inverters

The four common types of capacitors found in power conversion applications are: DC Link Capacitors: These capacitors smooth ripples during power conversion, store surplus energy

Top Signs Your Inverter Capacitor Needs

Aug 19, 2025 · Inverter capacitors that start to wear out or malfunction can cause inverter failure and be dangerous for components and users. This article

Exploring the Capacitor Technologies Needed in

May 8, 2024 · The electrical power systems in most modern technologies, like electric vehicles (EVs), are complex. In EVs specifically, power systems are

Using Capacitors with Solar Panels

Mar 30, 2021 · Yes, you can use capacitors with solar panels. But, only the supercapacitors are eligible to perform with solar panels. The supercapacitors

Flying Capacitors Explained

Apr 2, 2025 · Popular application areas for flying capacitors include EVs and solar inverters due to their lightweight, compact nature, and ability to help even out

CAPACITORS

Oct 20, 2021 · Three phase inductors and capacitors form the low pass filters. Resonant filters are specifically designed (inductance and capacitance) to "tune" out the harmonic frequencies. We

Inverter DC Link Capacitor Selection

Sep 10, 2019 · Properly sizing the DC link capacitor for a three phase inverter seems to be a skill that evades most power electronic engineers. The

Selecting dc-link capacitors for inverters

Feb 9, 2021 · The capacitor voltage rating must exceed the worst-case peak bus voltage as might arise under "high-line" mains conditions, maximum solar

DC-Link Design Tips

Sep 30, 2019 · DC-Link capacitors form an essential stage in power conversion for many applications, including three-phase Pulse Width Modulation (PWM)

Explanation of Inverter DC Capacitance and Inrush Current

Dec 14, 2023 · What is Inrush Current? During initial DC power connection to the inverter (a.k.a. cold start), the capacitor is in a discharged state and acts as a short circuit, until it accumulates

Low Inductance Film Capacitors for Inverter Applications

Mar 15, 2024 · ESL and placement of a capacitor contributes to overall induction of a circuit, which can cause voltage spikes during each switching cycle. These voltage spikes can exceed

How to fix capacitors in photovoltaic inverters

There are a lot of electrolytic capacitors in solar inverters, and in order to stabilize the voltage of the PV input and prevent interference, there are typically a variety of large-capacity electrolytic

Capacitor Technologies in EV Power Systems

May 9, 2024 · In EVs specifically, power systems are responsible for performing many tasks such as converting AC to DC and DC to AC as well as managing

How to Select DC Link Capacitor

The DC link capacitor is placed between the DC (in this case, the battery) and the AC (which is the load side) of the voltage inverter. The capacitor is placed

Capacitors in Power Electronics: A Simple

Apr 28, 2025 · In power electronics, capacitors are essential devices for energy storage, filtering, decoupling, and other functions. However, there are many

The Roles of Capacitors in EV Traction Inverter

Dec 13, 2023 · These capacitors act as filters, bypassing high-frequency noise. Decoupling Capacitors – In power supplies, decoupling capacitors are placed

Why capacitor used in a DC inverter?

Jan 27, 2025 · * DC Link Capacitor: The largest capacitor in a DC inverter is the DC link capacitor. It stores energy from the DC source (like a battery) and provides a stable DC voltage to the

Charging a Capacitor in Inverter:

Charging a Capacitor in Inverter - Inverters are static power converters for converting dc to ac. By controlling the conducting periods of the thyristors it is

Selecting and Applying DC Link Bus Capacitors for

May 16, 2023 · Figure 1 shows some of Cornell Dubilier''s DC Link capacitors for power inverters. Left photo features aluminum electrolytic capacitors of snap-in, plug-in, and screw-terminal

SECTION 4 SWITCHED CAPACITOR VOLTAGE

May 10, 2019 · The voltage doubler works similarly to the inverter; however, the pump capacitor is placed in series with the input voltage during its discharge cycle, thereby accomplishing the

Why dc link capacitor is required?

DC-link capacitors are used in order to provide a more stable DC voltage, limiting its fluctuations even under heavy current absorption by the inverter: in practice

Top Signs Your Inverter Capacitor Needs

Aug 19, 2025 · An inverter capacitor is a key electrical component that stores and releases electrical energy in power systems. It works alongside other

Capacitors for High Power

Mar 21, 2024 · The DC-link capacitor''s purpose is to provide a more stable DC voltage, limiting fluctuations as the inverter sporadically demands heavy current. A design can use different

Inverter and Types of Inverters with their

3 days ago · Classification of Inverters The term inverter was probably introduced by David Prince in 1925 and published an Article "The inverter". There are all

Looking Closer at DC Link Capacitors in Electric

Jul 3, 2024 · It also detects the motor''s speed and position and drives the insulated-gate bipolar transistor (IGBT) power stages. Figure 3. Simplified

Flying Capacitor Topology for Ultra Efficient Inverter

Jan 15, 2021 · 3 Principle of FC Inverters Here the topology of three-level (3L) and four-level (4L) Flying-Capacitor (FC) inverters are shown: Figure 2: Topology of 3L FC Inverter Compared to

Selecting and Applying Aluminum Electrolytic Capacitors

Jun 23, 2023 · Abstract— Aluminum electrolytic capacitors are widely used in all types of inverter power systems, from variable-speed drives to welders to UPS units. This paper discusses the

The Roles of Capacitors in EV Inverters

Jul 31, 2024 · The Role of Capacitors in EV Traction Inverter Application There are many different types of capacitors that ensure the efficient and effective

Basic Knowledge of Film Capacitors

Feb 18, 2022 · The demand for inverters used in environment-related equipment such as EVs/HEVs and solar/wind power generation systems is expanding in the capacitor market. For

Why is a DC Link Capacitor Used in an Inverter

Dec 23, 2024 · The DC link capacitor is a key player in inverter technology. It''s not just a passive component. Rather, it actively contributes to the inverter''s performance and efficiency. This

6 FAQs about [Are there capacitors in the voltage inverter ]

What is a capacitor in an inverter?

The primary function of a capacitor in an inverter is to manage and optimize the flow of electrical energy. Key roles include: Voltage regulation: Inverter capacitor assist in maintaining a consistent voltage level, preventing fluctuations that could potentially harm connected devices.

Why should you use an inverter capacitor?

Voltage regulation: Inverter capacitor assist in maintaining a consistent voltage level, preventing fluctuations that could potentially harm connected devices. Energy storage: Inverter capacitor store energy during periods of excess supply and release it during times of increased demand, contributing to a stable power output.

What is a switched capacitor voltage converter?

The two most common switched capacitor voltage converters are the voltage inverter and the voltage doublercircuit shown in Figure 4.1. In the voltage inverter, the charge pump capacitor, C1, is charged to the input voltage during the first half of the switching cycle.

How does a voltage inverter work?

In the voltage inverter, the charge pump capacitor, C1, is charged to the input voltage during the first half of the switching cycle. During the second half of the switching cycle, its voltage is inverted and applied to capacitor C2 and the load.

How do I choose the right inverter capacitor?

Choosing the right inverter capacitor: Selecting the appropriate capacitor for an inverter involves considering factors such as capacitance, voltage rating, and ESR (Equivalent Series Resistance). The choice depends on the specific requirements of the inverter's design and intended application. 5. Which type of inverter capacitor is best?

How many Ma can a switched capacitor inverter run?

Typical IC switched capacitor inverters have maximum output currents of about 150mA maximum. Switched capacitor voltage converters do not maintain high efficiency for a wide range of ratios of input to output voltages, unlike their switching regulator counterparts.

Industry Information

- China high voltage switchgear in Sweden

- Huawei Vietnam Outdoor Power Supply Factory

- Do charging piles need energy storage

- Hidden costs of inverter photovoltaics

- Is there electricity on the solar photovoltaic panels

- How much does a cobalt-lithium battery pack cost

- 13 5v lithium battery pack

- MalaysiaPenangSolar Dish Megawatt

- Energy storage stacking high voltage lithium battery

- Belgrade photovoltaic water pump inverter manufacturer

- Haiti Cadmium Telluride Photovoltaic Curtain Wall Manufacturer

- Flywheel energy storage for sale

- Are there any solar air conditioners for sale in N Djamena

- China backup inverter systems in Saudi-Arabia

- Simple structure of energy storage lithium battery pack

- 12v to 3000v inverter

- Congo 45kw high quality inverter company

- EK72v inverter 220v high power

- Abuja communication base station flywheel energy storage testing bidding

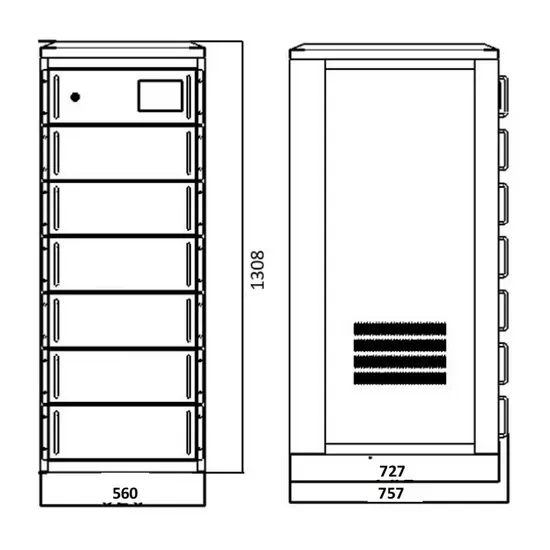

- Standard Specifications for Lithium Battery Energy Storage Cabinets

- Why are base station power supplies connected in parallel

- Pretoria Uninterruptible Power Supply UPS

- Kpd energy storage battery

Commercial & Industrial Solar Storage Market Growth

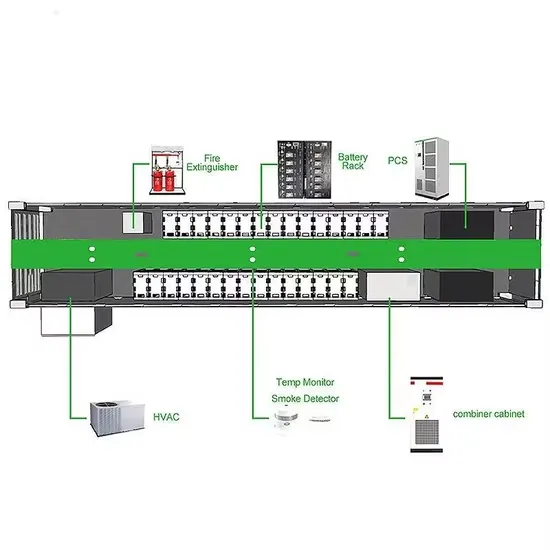

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.