A comparative life cycle assessment of silicon PV modules:

Sep 15, 2021 · Life Cycle Assessments (LCA) of single-crystalline silicon (sc-Si) photovoltaic (PV) systems often disregard novel module designs (e.g. glass-glass modules) and the fast pace of

Photovoltaic Glass Waste Recycling in the Development of Glass

Apr 3, 2023 · Because of the increasing demand for photovoltaic energy and the generation of end-of-life photovoltaic waste forecast, the feasibility to produce glass substrates for

Assessment of long term reliability of photovoltaic glass–glass modules

Apr 1, 2015 · Assessment of long term reliability of photovoltaic glass–glass modules vs. glass-back sheet modules subjected to temperature cycles by FE-analysis

The Use of Glass from Photovoltaic Panels at the End of

Nov 4, 2021 · This article deals with the use of photovoltaic panels at the end of their life cycle in cement composites. Attention is focused on the properties of cement composite after 100%

Sustainable Management of Photovoltaic Waste

Jan 10, 2025 · The rapid expansion of photovoltaic (PV) technology as a source of renewable energy has resulted in a significant increase in PV panel waste,

A comparative life cycle assessment of silicon PV modules:

Sep 15, 2021 · Abstract Life Cycle Assessments (LCA) of single-crystalline silicon (sc-Si) photovoltaic (PV) systems often disregard novel module designs (e.g. glass-glass modules)

Environmental analysis and comparison of the

Jul 21, 2024 · Furthermore, there is a direct associa-tion between the rise in fractal coating on panels and the reduction in environmental repercussions, approximately. This correlation

Life Cycle of Solar Panels: Durability and

Life Cycle Analysis (LCA) is an indispensable tool that we use to evaluate the environmental impacts of photovoltaic (PV) panels throughout their life span.

The use of recycled semiconductor material in crystalline silicon

Feb 1, 2020 · The analysis of the photovoltaic cell life cycle scenario including material recycling presented in this article was performed using SimaPro software and data combined and

Life cycle assessment and comparison of the conventional

Jan 9, 2025 · In this paper, utilizing the LCA method and SimaPro software, a comparative analysis has been done between conventional solar panels and fractal glass texture panels. In

Material intensity and carbon footprint of crystalline silicon

Feb 1, 2024 · The growing solar photovoltaic (PV) installations have raised concerns about the life cycle carbon impact of PV manufacturing. While silicon PV modules share a similar framed

Assessing the sustainability of solar photovoltaics: the case of glass

Sep 12, 2024 · The life cycles of glass–glass (GG) and standard (STD) solar photovoltaic (PV) panels, consisting of stages from the production of feedstock to solar PV panel utilization, are

Life cycle assessment of Al-Cu-Ag-Si recycling process from

Dec 1, 2024 · As raw materials become increasingly scarce, it is important to efficiently recycle PV panels to recover the highest quantity and quality of secondary raw materials. This study

The Use of Glass from Photovoltaic Panels at the End of

Figure 9. Graphic expression of flexural strengths after 2, 7, 28, 90 and 180 days. - "The Use of Glass from Photovoltaic Panels at the End of Their Life Cycle in Cement Composites"

Analysis of the Impact of Photovoltaic Curtain

Oct 10, 2023 · combines economy and carbon reduction. Through a carbon emissions calculation and economic analysis of replacing photovoltaic curtain

Recycling of End-of-Life Photovoltaic Panels Glass into

Sep 10, 2023 · However, the enormous quantity of installed PV panels has led to an issue concerning the disposal of end-of-life (EoL) PV panels. This paper thus explores the viability of

Analysis of Material Recovery from Silicon Photovoltaic

The non-silicon PV panels are treated by on chemical process to separate the different PV module components and 95 % of materials were claimed to be able to be recovered for use in

A Life Cycle Assessment of a recovery process from End-of

May 15, 2021 · A "gate to gate" approach was used to investigate two lines of activities: (i) the Recovery line, dedicated to the recovery of secondary raw materials from EoL c-Si PV panels,

Assessing Circular Economy in Photovoltaics: Life-Cycle

Feb 22, 2025 · The solar energy industry is one of the fastest growing industries in the world. The industry faces significant challenges due to a lack of effective end-of-life (EOL) management

NGA Presents Updated Resource on Glass

Mar 28, 2025 · NGA has published an updated Glass Technical Paper (GTP), FB39-25 Glass Properties Pertaining to Photovoltaic Applications, which is

The Use of Glass from Photovoltaic Panels at the End of

Nov 14, 2021 · Abstract:This article deals with the use of photovoltaic panels at the end of their life cycle in cement composites. Attention is focused on the properties of cement composite after

Transparent Solar Panels: Reforming Future

Feb 29, 2020 · What are transparent solar panels? Photovoltaic glass is probably the most cutting-edge new solar panel technology that promises to be a game

Recycling of photovoltaic modules for recovery and

Apr 1, 2023 · To note the recycling effects of photovoltaic (PV) modules on the environment, energy requirements, social aspects, and conventional and non-conventional life cycle

The Use of Glass from Photovoltaic Panels at the End of

Abstract:This article deals with the use of photovoltaic panels at the end of their life cycle in cement composites. Attention is focused on the properties of cement composite after 100%

Possibilities of use of glass recyclate from photovoltaic

Jun 18, 2019 · The paper deals with the possibilities of use of glass recyclate from photovoltaic panels for concrete masonry units. It compares different recipes and its physical and

Life Cycle Assessment of Coated-Glass Recovery

Nov 3, 2021 · Perovskite solar cells (PSCs) are emerging photovoltaic devices with great potential to become a terawatt-scale technology. To develop

Life cycle assessment of recycling waste crystalline silicon

Nov 15, 2024 · Crystalline silicon photovoltaic (PV) modules that have reached the end of their service life, if not effectively recycled, result in the loss of valu

Life Cycle Assessment of Current Photovoltaic Module

Apr 15, 2020 · In this report, the environmental life cycle assessment of the current generation recycling of crystalline silicon (c-Si) and cadmium telluride (CdTe) PV modules is described.

The Use of Glass from Photovoltaic Panels at the End of Their

Nov 4, 2021 · This article deals with the use of photovoltaic panels at the end of their life cycle in cement composites. Attention is focused on the properties of cement composite after 100%

The Use of Glass from Photovoltaic Panels at the

Nov 4, 2021 · The research has shown that it is possible to prepare cement composite based on recycled glass from solar panels, with compressive and

A Life Cycle Assessment of a recovery process from End-of

May 15, 2021 · As a consequence of the photovoltaic (PV) market expansion in the last 20 years, the cumulative global PV waste is expected to exponentially grow. A proper disposal of

The Use of Glass from Photovoltaic Panels at the

Nov 4, 2021 · This article deals with the use of photovoltaic panels at the end of their life cycle in cement composites. Attention is focused on the properties of

The Use of Glass from Photovoltaic Panels at the End of

Nov 4, 2021 · Due to the high percentage of recycled glass as one of the components of recycled photovoltaic panels, our research is focused on the use of this glass. The use of waste from

Life cycle and damage assessment of the third generation

Jan 1, 2024 · The glass used in a PV module must have outstanding optical qualities that enable the majority of the energy in the optical spectrum to pass through. The most common glass

Life Cycle Assessment of Recycling Waste Glass from Retired

Jul 29, 2025 · As the cumulative waste of retired photovoltaic (PV) modules is projected to exceed 1 million tons by 2030, the resultant loss of silicon, glass, and valuable metals has become a

Environmental impact assessment of the manufacture and use

Sep 10, 2024 · Hence, a global perspective on photovoltaic (PV) systems using life cycle assessment methodology is necessary. Here, we investigated the life cycle impacts of P- and

Environmental analysis and comparison of the conventional

Jul 21, 2024 · There are two major forms of solar energy that are typically utilized: photovoltaic and concentrated applications. The application of fractal glass texture to photovoltaic solar

6 FAQs about [The use cycle of photovoltaic glass]

What is photovoltaic waste?

Photovoltaic wastes are multi-material composites that contain diverse materials, such as, glass, metal rods and plastic; the amount of these materials on the photovoltaic waste depends on the type of solar panel [ 5 ]. However, crystalline silicon cells panels are the dominant waste in the generation of photovoltaic residues [ 6 ].

Can Photovoltaic Glass Waste be recycled?

Materials (Basel). 2023 Apr; 16 (7): 2848. Because of the increasing demand for photovoltaic energy and the generation of end-of-life photovoltaic waste forecast, the feasibility to produce glass substrates for photovoltaic application by recycling photovoltaic glass waste (PVWG) material was analyzed.

Can solar panel waste glass be recycled?

Diverse pathways of solar panel waste glass recycling have been proposed; the most common is its reincorporation to the solar panel production [ 7, 8 ].

How can life cycle inventories of PV module recycling be used?

The life cycle inventories of PV module recycling according to the cut-off modelling approach can be used to complement existing life cycle inventory data on PV systems.

How does transport of solar PV panels affect life-cycle energy consumption?

Transportation of small number of solar PV panels over long distances causes increase in life-cycle energy consumption and related GHG emissions. Thus, if the STD type panel is installed in Lithuania, its life-cycle GHG emissions from transportation are 0.002–0.78 tCO 2eq.

How is energy used in solar PV panels calculated?

The energy used in the utilization of solar PV panels (cells, ribbons, back sheets, glass, frame, EVA, and POE films) \ ( {\text {E}}_ {\text {U}}\) is calculated by considering the weight of the utilized components.

Industry Information

- South Korean supercapacitor manufacturer

- Which type of energy storage product does PV storage belong to

- Armenian coal-to-electricity energy storage equipment manufacturer

- How many 5G transformation base stations does Nepal have

- Romanian outdoor communication battery cabinet export company

- Solar Gel Inverter Battery

- Jamaica power plant clean photovoltaic energy

- 670wp monocrystalline photovoltaic panel

- Ankara Solar Water Pump Wholesalers

- Jordan inverter manufacturers quote

- 6000w solar inverter for sale in Lisbon

- Voc uninterruptible power supply requirements

- 6g communication power base station

- Ess mechanical increase price

- What is the size of the battery cabinet in centimeters

- Baku shingled solar panels

- Professional Solar Photovoltaic System

- Uganda Industrial Energy Storage

- How many watts is the inverter 60a

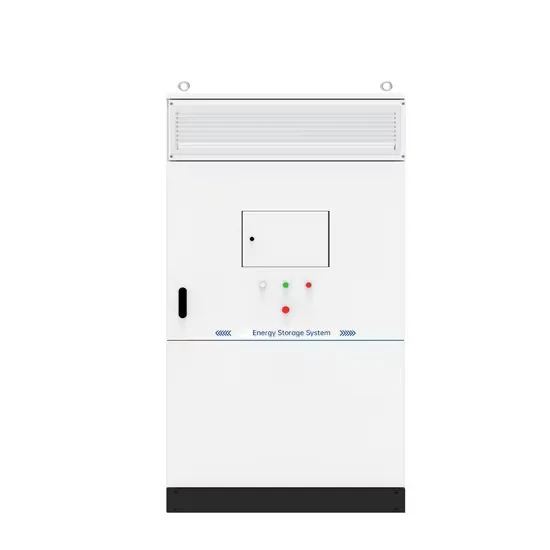

- Energy storage cabinet for base station of telecommunication company

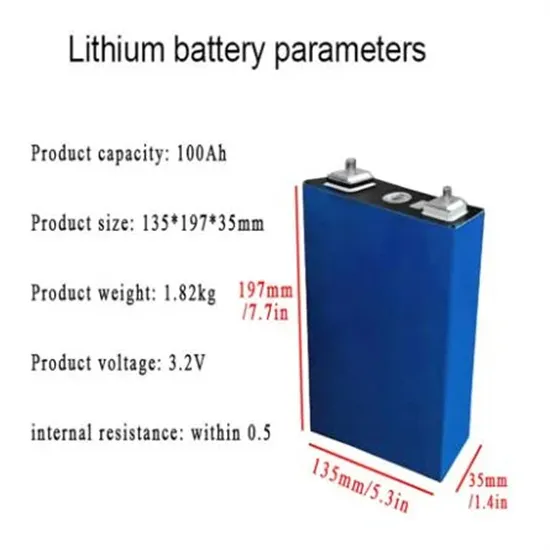

- Battery cabinet 25kw

- Large-scale sun shed photovoltaic panel manufacturer

- Netherlands 96v to 220v inverter quotation

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.