Economically Sustainable Growth of Perovskite Photovoltaics

Apr 15, 2020 · We present two technoeconomic models that analyze the sustainable growth of perovskite manufacturing for an R2R single-junction technology and a perovskite-silicon

Photovoltaic (PV) Module Technologies: 2020 Benchmark

Nov 1, 2021 · This report benchmarks 2020 PV module minimum sustainable price (MSP) via bottom-up manufacturing cost analysis, for established PV technologies in mass production,

Economically Sustainable Growth of Perovskite

Apr 10, 2020 · We present two technoeconomic models that analyze the sustainable growth of perovskite manufacturing for an R2R single-junction technology and a perovskite-silicon

Perovskite Solar Cell Market Size, Share & Growth

Oct 22, 2024 · The perovskite solar cell market Size is projected to grow from USD 271 million in 2024 to USD 2,268 million by 2028, growing at a CAGR of

Solar Manufacturing Cost Analysis | Solar Market

Aug 7, 2025 · Solar Manufacturing Cost Analysis NREL analyzes manufacturing costs associated with photovoltaic (PV) cell and module technologies and

Microquanta developing perovskite solar

Feb 17, 2025 · The Chinese perovskite solar cell and module maker said its custom-designed double-glass perovskite modules measure 1,200 mm x

pv magazine International – News from the

6 days ago · News from the photovoltaic and storage industry: market trends, technological advancements, expert commentary, and more.

The levelized cost of electricity from perovskite

Sep 27, 2022 · For example, in thin-film modules (such as perovskite single junctions and all-perovskite tandem modules) the CTM losses regard the p1,

Perovskite Solar Cell Price

1 day ago · Need perovskite solar cell prices? Compare 220,000+ products from 41,000+ global suppliers. Get tiered pricing, MOQ options, and certified solutions. Click for instant quotes!

GCL Optoelectronics finishes 1 GW perovskite

Jun 26, 2025 · GCL Optoelectronics has commissioned a 1 GW perovskite solar module facility in China, and says it may increase capacity to 2 GW per year

Chinese startup unveils flexible perovskite photovoltaic modules

Jan 14, 2025 · Mellow Energy claims its ML-Flex panel is currently the world''s largest flexible perovskite solar module. Available in five versions with power output ranging from 260 W to

CHINA ROUND-UP: UtmoLight, UtmoLight and

Feb 11, 2025 · Once the project reaches full capacity, it is expected to produce approximately 1.8 million perovskite PV modules annually. Image: UtmoLight.

CSI Solar Releases Interim Report: Aims for 33% Efficiency in

1 day ago · In the photovoltaic module segment, during the reporting period, CSI Solar focused on the research, development, and industrialization of core module technologies, achieving

Bottom-up cost model for perovskite solar

Jul 3, 2025 · Scientists in Switzerland have conducted techno-economic analysis of perovskite solar module manufacturing costs in terms of levelized cost of

Oxford PV starts commercial distribution of

Sep 5, 2024 · Oxford PV is delivering its first commercial perovskite solar modules to US customers. The 72-cell solar modules have an efficiency of

Perovskite Photovoltaic Market 2025-2035:

Jan 7, 2025 · Current price forecasts by IDTechEx see perovskite/silicon tandem solar modules to be comparative in price to single junction silicon solar, by

Perovskite Photovoltaic Modules Market

May 13, 2025 · The perovskite photovoltaic (PV) module market is poised for rapid expansion, driven by advancements in efficiency, flexibility, and cost-effectiveness. Among end-use

Design and Cost Analysis of 100 MW Perovskite

Aug 19, 2022 · Overall, perovskite PV production has the potential of being competitive with other PV technologies even at smaller scales of production,

IPVF''s PV technology vision for 2030

Jul 20, 2020 · This c-Si module price value is then used together with the extrapolated module efficiency to 2030 in an LCOE calculation for two different

How does the cost of perovskite solar cells

Feb 9, 2025 · For perovskite-silicon tandem modules produced in the U.S., costs range from approximately $0.29/W to $0.42/W, depending on efficiency and

Perovskite Photovoltaics

Jan 16, 2025 · Perovskite photovoltaics have garnered significant attention as alternative solar power technologies due to their lightweight and flexible

Solar Manufacturing Cost Analysis | Solar Market

Aug 7, 2025 · NREL analyzes manufacturing costs associated with photovoltaic (PV) cell and module technologies and solar-coupled energy storage

Solaires Entreprises ships indoor perovskite PV modules to

1 day ago · Solaires Entreprises, a Canadian perovskite startup, has begun supplying indoor PV modules for integration into sensor devices, marking its first commercial shipment.

Perovskite Solar | Perovskite-Info

Feb 2, 2025 · This 3rd generation of PVs includes DSSC, organic photovoltaic (OPV), quantum dot (QD) PV and perovskite PV. A perovskite solar cell is a

Design and Cost Analysis of 100 MW Perovskite

Aug 19, 2022 · (34) A further report suggests an MSP of 0.25–0.27 $/Wp for silicon panels and an MSP of 0.38 $/Wp for perovskite solar panels

NREL, CubicPV achieves 24% efficiency for

Jul 10, 2025 · A U.S.-based collaboration between the National Renewable Energy Laboratory (NREL) and CubicPV has yielded a perovskite minimodule

The hope and hype of commercial perovskites

Feb 10, 2025 · Will Norman asks if mass-scale deployment of perovskite technology is now imminent and whether it could unseat crystalline silicon as

Manufacturing Cost Models for Perovskite/Silicon Tandem Modules

Jun 14, 2024 · Here we present manufacturing cost models to assess the economic competitiveness of potential module designs. We compare two- and four-terminal (2T and 4T)

Perovskite Solar Panels

Utility-scale solar farms deploy large quantities of perovskite photovoltaic panels to supply renewable energy to the grid. They generate bulk power used by utilities and feed electricity to

GCL says perovskite solar module passes silicon

Jun 20, 2024 · At Intersolar Europe, the Chinese manufacturer also said the perovskite-silicon tandem module would cost 50% of a crystalline silicon

Cost Effectivities Analysis of Perovskite Solar Cells: Will it

Apr 15, 2025 · Current manufacturing cost of perovskite solar modules is calculated as 0.57 $ W −1 much higher than that of the silicon solar cells. Cost Effectivities analysis indicates that

Perovskite Photovoltaic Modules Market

May 13, 2025 · Quick Q&A Table of Contents Infograph Methodology Purchase/Customization Regulatory and Policy Frameworks Shaping Perovskite Photovoltaic Module Adoption The

Photovoltaic (PV) Module Technologies: 2020 Benchmark

Aug 9, 2025 · This report benchmarks 2020 PV module minimum sustainable price (MSP) via bottom-up manufacturing cost analysis, for established PV technologies in mass production,

Cost-Performance Analysis of Perovskite Solar

Sep 15, 2016 · 1 Introduction The photovoltaic (PV) market has increased dramatically during recent decades. In 2014, there were about 40 GW of PV

Perovskite Solar Cells: Advantages, Challenges,

Discover the potential of perovskite solar cells in revolutionizing renewable energy. Learn about their advantages, current research advancements,

Tandem PV

Tandem PV''s design boosts the output of conventional solar modules by combining them with thin-film perovskite. We are producing tandem perovskite

6 FAQs about [Perovskite photovoltaic module price]

What is the cost effectivities of perovskite solar cells?

Cost Effectivities analysis indicates that materials cost shares 70% of costs, and capital cost and other cost share nearly 15%, respectively. The commercialization of perovskite solar cells (PSCs) has garnered worldwide attention and many efforts were devoted on the improvement of efficiency and stability.

What is a perovskite solar cell?

Perovskite solar cells (PSCs), as the next generation PV technology, have been receiving widespread attention since its appearance because of high efficiency and potentially low manufacturing cost .

Can perovskite PV production be competitive with other PV technologies?

Overall, perovskite PV production has the potential of being competitive with other PV technologies even at smaller scales of production, assuming the stability of the solar cells is sufficient, and the lab-made perovskite efficiency translates well into larger perovskite modules.

How many perovskite solar companies are there in China?

There are over 100 perovskite solar companies in China, with ca. 20 of them having established 100 MW manufacturing lines. Reliable data including material and equipment costs are available for these manufacturing lines, making the 100 MW manufacturing line in China a suitable basis for estimating manufacturing costs.

Are perovskite modules stable?

The PSMs manufactured by the perovskite companies have also made progress in stability, for example, several Chinese companies announced their modules have also passed the test by the IEC 61215 standards . Besides the efficiency and stability, the cost of PSCs is also a critical issue for their commercialization.

Is a perovskite active layer viable for commercial-scale manufacture?

By careful selection of the materials, a configuration of the perovskite active layer viable for commercial-scale manufacture was identified. A bottom-up cost modeling approach was used to determine the material and production costs of the PSCs.

Industry Information

- Hot sale reset circuit breaker factory supplier

- Angola s photovoltaic power generation and energy storage advantages

- The largest solar energy storage field in Porto Portugal

- Eastern European lithium iron phosphate portable energy storage products

- Flexible photovoltaic panel BESS roof

- Dhaka three phase inverter installation

- High quality 1000 amp breaker in Nicaragua

- Hargeisa Telecom Base Station Room Project

- Apia Aluminum Alloy Battery Energy Storage Container Quote

- 10W 16V solar panel

- Smart photovoltaic panel manufacturer in Manchester UK

- Solar power generation price for communication base stations

- Skopje Solar Energy Storage Power Company

- 300wh power station for sale in France

- Inverter quality power ratio

- Oceania computer room battery cabinet manufacturer

- Tuvalu Green Solar Water Pump Requirements

- Khartoum container energy storage company ranking

- Single-phase inverter with closed loop

- Kinshasa Power Station Energy Storage Equipment

- Turkey Izmir New Energy Storage Policy

- Residential Solar Photovoltaic Systems in Slovenia

- Advantages of Solar Communication Base Stations

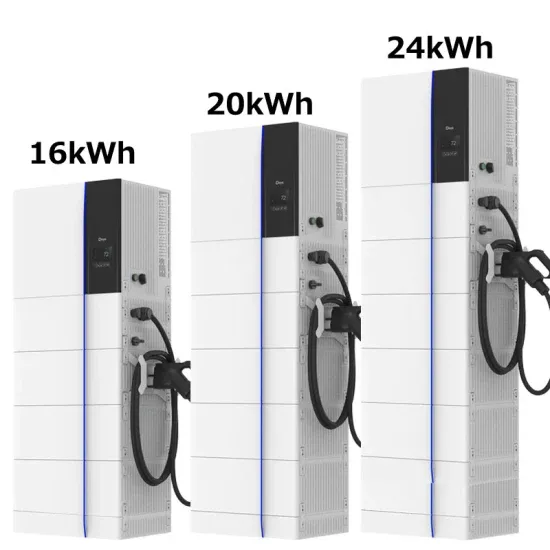

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.