Battery Discharge Testing: Implementing NERC

Jan 10, 2023 · There are a number of different tests like: visual inspections, specific gravity, float voltage and current measurements, discharge test, individual cell condition, inter-cell

Communication Base Station Battery test Load 10-60v

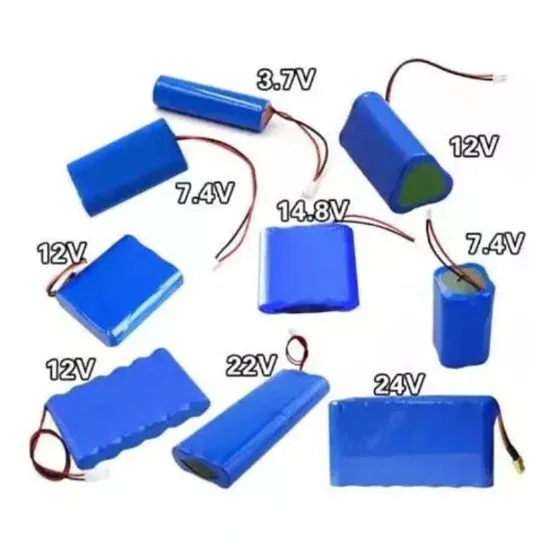

Application Battery Pack, Battery Cell, detect battery, test battery capacity Input Resistance 1MΩ Charge/Discharge Voltage 48V Brand Name FORESISGHT Model Number FST-CT2448V

Evaluating the Dispatchable Capacity of Base Station Backup Batteries

Apr 21, 2021 · Cellular base stations (BSs) are equipped with backup batteries to obtain the uninterruptible power supply (UPS) and maintain the power supply reliability. While

Communication Base Station Battery test Load 48v50A Capacity test

Battery Pack, Battery Cell, detect battery, test battery capacity Charge/Discharge Voltage 220V Brand Name FORESISGHT Model Number FST-CT48V/50A Type battery capacity tester,

Communication Base Station Battery test Equipment 60v

Type battery capacity tester, battery load tester, internal resistance tester Support battery Lithium Battery Maximum Measuring Voltage 30v Flashlight LCD Group Voltage Range 20V-60V Cell

CTECHI 5G Telecom Base Station Battery 48V

CTECHI 5G Telecom Base Station Battery 48V 50Ah Power System Solution UPS Backup Battery The CTECHI 50Ah 48V LiFePO4 Battery is a high

Base station battery discharge test method

How to proceed the discharge test ?Gather the necessary equipment: You will need a battery or group of batteries, a discharge load, and a way to measure the voltage and current of the

Communication Base Station Battery test Load 48v70A Capacity test

Battery Pack, Battery Cell, detect battery, test battery capacity Charge/Discharge Voltage 220V Brand Name FORESISGHT Model Number FST-CT48V/70A Type battery capacity tester,

OVERVIEW OF TELECOM BASE STATION BATTERIES

How to proceed the discharge test ?Gather the necessary equipment: You will need a battery or group of batteries, a discharge load, and a way to measure the voltage and current of the

TELECOM BASE STATION BATTERY SOLUTIONS WHAT YOU

Battery discharge testing, also known as battery load testing, is a process that test battery health statement by constant current discharging of the set value by continuously the discharge

Communication Base Station Battery test Equipment 24v 48v

Type battery capacity tester, battery load tester, internal resistance tester Support battery Lithium Battery Maximum Measuring Voltage 30v Flashlight LCD Group Voltage Range 20V-60V Cell

Base station battery charging and discharging test

What is a battery discharge test? Among all the tests, the discharge test (also known as load test or capacity test) is the only test that can accurately measure the true capacity of a battery

Simplify Voltage and Current Measurement in Battery

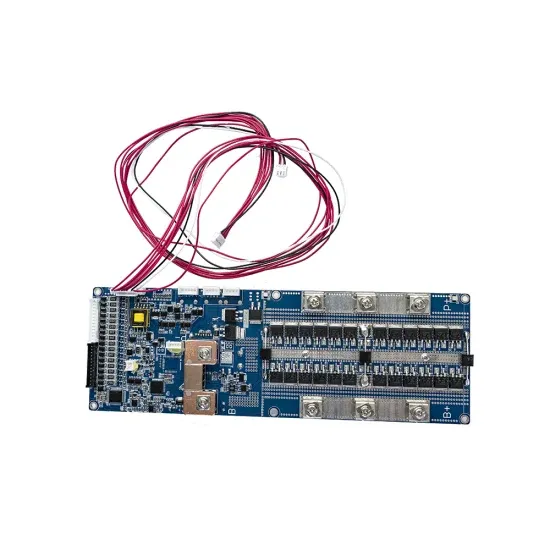

Dec 23, 2023 · Battery test equipment is used to verify battery pack functionality and performance prior to shipment to the customer. This application brief outlines three major functional tests

Communication Base Station Battery test Equipment 24v 48v

This is why so important to check batteries regular intervals, and the only reliable way of measuring battery capacity is to conduct a discharge test. Product Paramenters

Communication Base Station Battery test Load 48v200A Capacity test

Battery Pack, Battery Cell, detect battery, test battery capacity Charge/Discharge Voltage 220V Brand Name FORESISGHT Model Number FST-CT48V/200A Type battery capacity tester,

How to test and evaluate your battery

The IEEE 1188 standard defines the recommended practices, frequency and type of measurements necessary for maintenance, testing and replacement of

Q&A: Battery testing

Feb 17, 2025 · With these differences in mind, a 50% – 100% change from baseline is a good screening criterion for VLA batteries but with VRLA batteries you may want to consider being a

Communication Base Station Battery test Load 48v60A Capacity test

Battery Pack, Battery Cell, detect battery, test battery capacity Charge/Discharge Voltage 220V Brand Name FORESISGHT Model Number FST-CT48V/60A Type battery capacity tester,

Maintenance Points for Telecom Base Station Batteries

The float charge voltage at a certain actual temperature U = U0 (25°C) + (25-t) × 0.003 (t = ambient temperature ). (7) During float charging, the maximum difference in voltage of each

5g Base Station Battery Backup Power Quality Analyzer Battery Test

Aug 1, 2025 · Through these basic functions, the test system can carry out battery performance testing, rate charge and discharge testing, capacity testing, cycle life testing, DC internal

Base station battery manufacturer

Mar 26, 2025 · Base station battery manufacturer customized Base station battery systems with 52V 48V 26V 200Ah 150Ah 100Ah 10kWh 5kWh 7kWh.

Communication Base Station Battery test Load 48v80A Capacity test

Battery Pack, Battery Cell, detect battery, test battery capacity Charge/Discharge Voltage 220V Brand Name FORESISGHT Model Number FST-CT48V/80A Type battery capacity tester,

Base station battery pack current test

A Telecom base station battery is the need of the hour and you cannot deny that. From our minor daily life activities to major work forms, we need electricity all the time. Therefore, the best

Q&A: Battery testing

Feb 17, 2025 · Q: The IEEE standards that cover maintenance and testing of batteries include this recommendation for the six-month maintenance interval: "Verify that the station battery can

TELECOM BASE STATION BATTERY SOLUTIONS WHAT YOU

Base station battery discharge test method How to proceed the discharge test ?Gather the necessary equipment: You will need a battery or group of batteries, a discharge load, and a

Addressing DC Power Test Challenges for Base Station

Electronic subassemblies for base stations derive individual circuit voltages from a main DC bus voltage through a series of DC/DC regulators. Due to the complexity of their distributed power

(PDF) Performance Analysis of VRLA Battery for

Oct 22, 2021 · This has shortened the battery life at the Base Station (BTS). This study aims to analyze the performance of a (new) VRLA battery against a DC

Base station battery charging and discharging test

Among all the tests, the discharge test (also known as load test or capacity test) is the only test that can accurately measure the true capacity of a battery system and in turn determine the

Communication Base Station Battery test Load 48v90A Capacity test

Battery Pack, Battery Cell, detect battery, test battery capacity Charge/Discharge Voltage 220V Brand Name FORESISGHT Model Number FST-CT48V/90A Type battery capacity tester,

6 FAQs about [Base station battery voltage test]

How to test a battery bank?

There are a number of different tests like: visual inspections, specific gravity, float voltage and current measurements, discharge test, individual cell condition, inter-cell resistance, and others, which are recommended in IEEE, NERC and other standards for diagnosing the condition of the battery banks.

What are the measures necessary to validate the condition of the battery?

This standard describes the measures necessary to validate the condition of the battery, as well as the replacement criteria, the frequency of capacity tests, corrective actions, etc. * Monthly inspections that include ripple current and voltage, charger output current and voltage, temperature, float charge current, etc.

What is a battery capacity test?

Although many tests can be performed to assess the condition of the batteries such as ohmic testing, specific gravity, state of charge etc., only the capacity test, commonly referred to as the discharge or load test, can measure the true capacity of the battery system and in turn determine the state of heath of the batteries.

What is a battery discharge test?

Among all the tests, the discharge test (also known as load test or capacity test) is the only test that can accurately measure the true capacity of a battery system and in turn determine the state of health of batteries.

What is battery test equipment?

Battery test equipment is used to verify battery pack functionality and performance prior to shipment to the customer. This application brief outlines three major functional tests that a battery tester performs while showing how to achieve the desired level of regulated error. ADC Figure 1. Traditional Battery Test Equipment Block Diagram

What is a battery performance test?

A performance test is defined as “a constant-current or constant-power capacity test made on a battery after it has been in service”2. It is the most commonly used discharge test method and it determines if the battery is performing according to the manufacturer’s specifications and/or if it is within acceptable limits.

Industry Information

- Funafoti lithium battery energy storage battery brand

- The role of liquid-cooled battery energy storage cabinet

- Solar power storage options in Victoria

- Huawei photovoltaic inverter afci price

- Perovskite photovoltaic panel purchase price

- Victoria Portable Power Storage Enterprise

- Which is the best 20kw energy storage in Lagos Nigeria

- West Asia Crystalline Silicon Photovoltaic Glass

- Villa split solar system

- High quality wholesale household inverters manufacturer

- Energy storage electric vehicle charging pile sales manufacturer

- Energy storage container benefits

- Battery cabinet base station energy sheet

- Mibai Energy Storage Power Supply

- Kigali Solar Panel Assembly

- Sao Tome LTE emergency communication base station EMS supplier

- Conversion equipment battery cabinet replacement conditions

- Kuwait Energy Storage Low Temperature Lithium Battery Factory

- Pull-type outdoor power supply

- Philippines Cebu Solar Photovoltaic Power Station System

- Monrovia off-grid energy storage system manufacturer

- 60ah connected to inverter

- Lithium iron phosphate battery station cabinet composition

Commercial & Industrial Solar Storage Market Growth

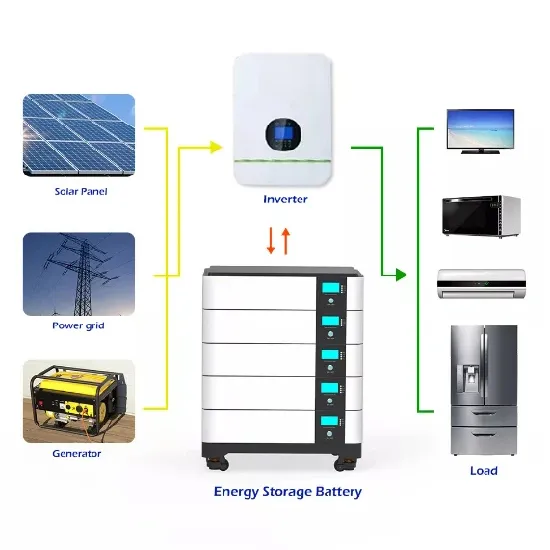

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.