The Assembly Process of 20ft Energy Storage

Aug 26, 2024 · Whether you need a solution for offshore energy storage, industrial power backup, or renewable energy integration, our containers are

1000 kWh Battery Storage Manufacturer | HT Infinite Power

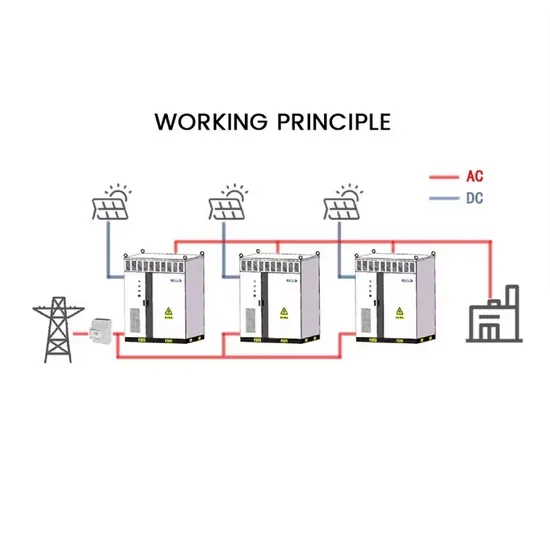

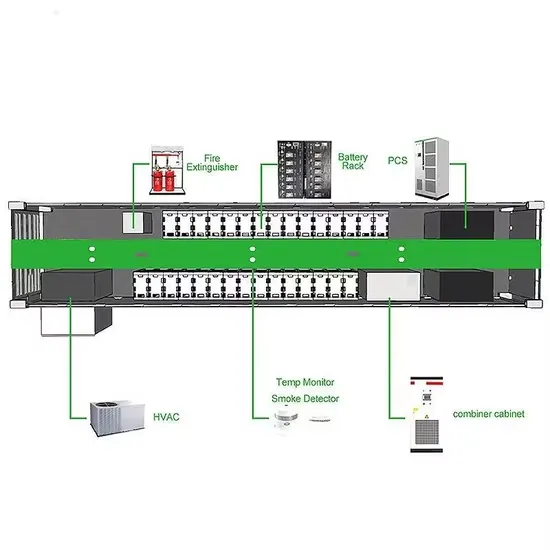

HT Infinite Power 500kw 1000kwh battery storage systems outdoor container adopts advanced 6S intelligent management technology, including EMS, PCS, BMS, fire protection system,

Utility Battery Energy Storage System (BESS) Handbook

Oct 7, 2024 · The life-cycle process for a successful utility BESS project, describing all phases including use case development, siting and permitting, technical specification, procurement

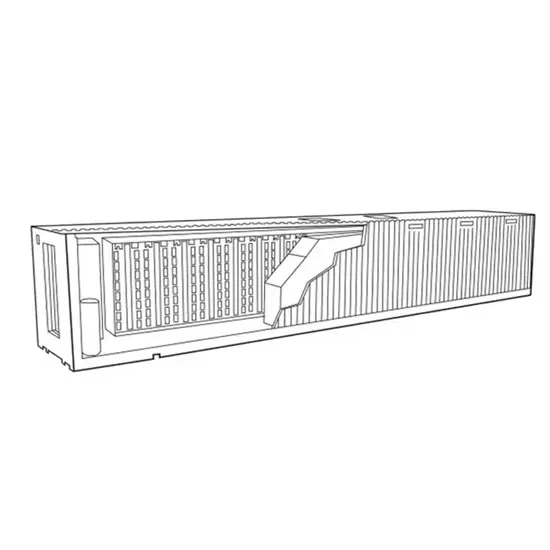

Energy Storage Container Production Line

Project Content: Energy Storage Container Assembly Line Production Cycle Time: 40min Key Processes: - Container loading - Cooling system installation - Automated electrical cabinet

Energy storage container, BESS container

6 days ago · What is energy storage container? SCU uses standard battery modules, PCS modules, BMS, EMS, and other systems to form standard

Energy Storage System

6 days ago · CATL''s energy storage systems provide energy storage and output management in power generation. The electrochemical technology and renewable energy power generation

DeepL翻译:全世界最准确的翻译

1 day ago · 即时翻译文本&完整的文档文件。为个人和团队提供准确的翻译。每天有数百万人使用DeepL进行翻译。

Battery Pack Assembly Process Series 7

Jun 6, 2025 · Whether it is used for new energy vehicles or energy storage scenarios, the core function of the battery pack is to store energy. "If the battery pack is compared to a soldier in

Energy storage container battery assembly sequence

What is a battery energy storage system (BESS) container design sequence? The Battery Energy Storage System (BESS) container design sequence is a series of steps that outline the design

Energy Storage Container Assembly Line

Technical Parameter ﹀ Highlights of Energy Storage Container Assembly Line ﹀ Automatic container launch, door opening, cleaning, pre-install, and

Container-Type Energy Storage System

Container-Type Energy Storage System——It can efficiently store a large amount of electrical energy, while having efficient energy conversion and release

2000 kWh Battery Storage Manufacturer | HT

HT energy storage battery 1000kw 2000 kwh battery Outdoor Container ESS could be used for renewable energy storage as a backup power,it also could

Energy storage container testing process

Energy storage container testing process What is energy storage performance testing? Performance testing is a critical component of safe and reliable deployment of energy storage

The Assembly Process of 20ft Energy Storage

Aug 26, 2024 · In the manufacturing of 20ft energy storage containers, the assembly process is a critical step that ensures the quality, safety, and

Energy storage container assembly design

What is a battery energy storage system (BESS) container design sequence? f a containerized energy storage system. This system is typically used for large-scale energy storage

HOW TO DESIGN A BESS (BATTERY ENERGY

Mar 11, 2023 · The design of a BESS (Battery Energy Storage System) container involves several steps to ensure that it meets the requirements for safety,

Understanding the Battery Cell Assembly Process

Nov 11, 2023 · The battery cell assembly process must continue to evolve to ensure that it remains a reliable, efficient, and sustainable method of storing

News

Oct 19, 2022 · Pre-installed energy storage container has completed the assembly, installation and factory inspection and testing of the whole system

ABB containerized energy storage offers plug-in

Sep 8, 2021 · • The Containerized Energy Storage System (ESS) integrates sustainable battery power for existing ships in a standard 20ft container • All

Container energy storage battery manufacturing process

A battery energy storage system (BESS) captures energy from renewable and non-renewable sources and stores it in rechargeable batteries (storage devices) for later use. A battery is a

Container Energy Storage: How It Powers the Future of Renewable Energy

Jun 1, 2025 · What''s the Big Deal with Container Energy Storage Systems? a standard shipping container, the same kind you''d see on cargo ships, quietly humming in a field. But instead of

Containerized Energy Storage System: How it

Jul 12, 2023 · A Containerized Energy-Storage System, or CESS, is an innovative energy storage solution packaged within a modular, transportable container. It

Energy storage container assembly line process standards

Container Energy Storage System (CESS) is an integrated energy storage system developed for the mobile energy storage market. It integrates battery cabinets, lithium battery management

Lebanon Energy Storage Container Assembly House: The

The "Why Didn''t We Do This Sooner?" Factor A Beirut textile factory''s manager joked: "Our old generator was like a grumpy old uncle – loud, expensive, and unreliable. The new container

Energy storage container system assembly process

ABB''s containerized energy storage system is a complete,self-contained battery solution for large-scale marine energy storage. The batteries and all control,interface,and auxiliary equipment

Battery Pack Assembly Process Series 7

Jun 6, 2025 · The manufacturing quality of energy storage containers highly relies on precise and reliable equipment support - whether it is the production consistency of battery units, the

HuiYao Intel

Aug 5, 2025 · Explore our exclusive range of ready-to-deploy BESS energy storage solutions and containers, Battery Pack Production Line, Home energy

The BESS System: Construction, Commissioning,

3 days ago · A comprehensive guide on the construction, commissioning, and operation & maintenance of industrial and commercial energy storage systems.

Energy Storage Container Assembly Process Video: Your

Ever wondered why energy storage container assembly process videos are going viral in renewable energy circles? As global battery storage capacity is projected to reach 1.6 TWh by

WHAT IS THE PROCESS OF CONTAINER

Feb 22, 2022 · THE PROCESS OF CONTAINER MANUFACTURING Step 1: a. preprocessing of sheet and section steel b. cutting and processing of section

ETN News | Energy Storage News | Renewable

3 days ago · ETN news is the leading magazine which covers latest energy storage news, renewable energy news, latest hydrogen news and much more.

What the process of assembly of industrial energy storage

In this article, we will provide a step-by-step overview of the process of implementing an industrial energy storage system, what formalities need to be fulfilled and what to pay special attention

Account Suspended

Aug 4, 2025 · Commercial-level energy storage systems play a crucial role in balancing the grid and ensuring power supply stability. Lithium-ion containerized batteries have become

6 FAQs about [Energy storage container system assembly to factory delivery process]

How are battery energy storage systems transported?

Given the Battery Energy Storage System’s dimen- sions, BESS are usually transported by sea to their destination country (if trucking is not an option), and then by truck to their destination site. A.Logistics The consequence is that the shipment process can be worrisome.

Do battery energy storage systems look like containers?

C. Container transportation Even though Battery Energy Storage Systems look like containers, they might not be shipped as is, as the logistics company procedures are constraining and heavily standardized. BESS from selection to commissioning: best practices38 Firstly, ensure that your Battery Energy Storage System dimensionsare standard.

When does an energy storage project start?

“The operations and maintenance phase of an en- ergy storage project begins when the system has been successfully commissioned and the owner has obtained approval to operate the system.

What should be included in a contract for an energy storage system?

Several points to include when building the contract of an Energy Storage System: • Description of components with critical tech- nical parameters:power output of the PCS, ca- pacity of the battery etc. • Quality standards:list the standards followed by the PCS, by the Battery pack, the battery cell di- rectly in the contract.

What is a battery energy storage system (BESS) e-book?

This document e-book aims to give an overview of the full process to specify, select, manufacture, test, ship and install a Battery Energy Storage System (BESS). The content listed in this document comes from Sinovoltaics’ own BESS project experience and industry best practices.

What chemistry is used in battery energy storage system?

Do a quick research. •Battery cell chemistry:LFP (Lithium iron phos- phate – chemical formula LiFePO4) is the main chemistry used in the Battery Energy Storage System industry due to lower cost and increased safety.

Industry Information

- Manama Energy Storage Container Customization

- Micro flywheel energy storage system

- Brunei user-side industrial and commercial energy storage solution

- Base station wind power cabinet battery

- Factory price 15kv switchgear in Canberra

- Main circuit breaker factory in Burundi

- Huawei Panama Colon Large Energy Storage Cabinet Wholesaler

- What are the energy storage power sources for 15 kWh of electricity

- Huawei large ups uninterruptible power supply

- Praia s new solar photovoltaic panels

- What is the energy storage battery manufacturer in Brazil

- Single-sided and double-sided types of photovoltaic modules

- Dushanbe aluminum alloy battery energy storage container sales

- EU TCL solar photovoltaic panels

- Liquid flow zinc energy storage battery

- 540w photovoltaic panel export manufacturer

- Photovoltaic container inverter

- Inverter battery pack charging

- Best high quality voltage breaker distributor

- Mobile power portability recommendation

- How to choose a container generator

- How many watts does the Nanya solar street light have

- Israel wall mounted inverter custom manufacturer

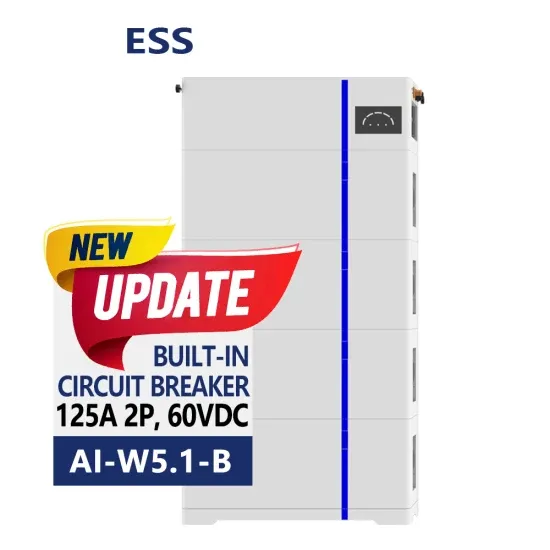

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.