Lithium Battery Grade PVDF

The global market for Lithium Battery Grade PVDF was estimated to be worth US$ 4142.4 million in 2023 and is forecast to a readjusted size of US$ 13780 million by 2030 with a CAGR of

How is PVDF used in lithium ion batteries?

Apr 16, 2024 · PVDF is known for its excellent compatibility with lithium-ion battery electrolytes. It exhibits good solubility in common organic solvents, allowing it to form a homogeneous

Lithium-ion battery separators based on electrospun PVDF:

Jul 1, 2022 · Abstract Separator is an essential component in lithium-ion batteries (LIBs), which greatly affects the electrochemical performance of the battery. Poor electrochemical

Understanding PVDF Binder for Lithium Ion Battery

2 days ago · Polyvinylidene fluoride (PVDF) is one of the most widely used binders for both the cathode and anode in lithium batteries, drawing significant attention from researchers. PVDF

Lithium Battery Grade Pvdf Market Size & Future Growth 2032

Jul 4, 2024 · The market growth is attributed to the increasing demand for lithium-ion batteries in electric vehicles, consumer electronics, and energy storage systems.The Global Lithium

Research progress on energy storage performance

Oct 15, 2023 · Currently, significant progress has been made in the research of PVDF-based composites, with numerous attempts to enhance their energy storage performance. As shown

PVDF: Why is it the material of choice for the lithium battery

Feb 12, 2025 · PVDF has certain flame retardant properties, which can slow down the burning speed of the battery to a certain extent and improve the safety of the battery. This is

Alternative binders for sustainable

Broader context Compared to other technologies, electrochemical storage offers the most energy efficient way to store electricity produced from renewable

PVDF Solutions for Lithium Ion Battery

5 days ago · Lithium Ion Battery Kynar® and Kynar Flex® PVDF resins are used extensively in battery applications as binders and separator coatings.

Polyvinylidene Fluoride as an advanced polymer for

Aug 25, 2023 · Additionally, PVDF-based nanocomposites are widely used in various applications such as supercapacitors, ultrafiltration membranes, memory storage devices and separators

A review on polyvinylidene fluoride polymer based

Apr 1, 2022 · Dielectric polymer nanocomposite materials with great energy density and efficiency look promising for a variety applications. This review presents the research on Poly (vinylidene

Revealing the PVDF Binder Performance for Li

Jan 2, 2025 · Challenges with PVDF Binder While PVDF offers excellent performance in many ways, there are some challenges associated with its

Application of Polyvinylidene Fluoride Binders in Lithium-Ion Battery

Jan 1, 2015 · Abstract Binder is a passive but an important part of lithium-ion battery (LIB), which provides interconnectivity within each electrode facilitating electronic and ionic conductivity.

Improving Electrochemical Performance Of PVDF

Enhanced PVDF performance can lead to increased battery efficiency, longevity, and safety, potentially reducing the overall cost of battery production and

High-Performance-Materials-for-Batteries_EN

Jul 18, 2018 · Solef® PVDF Binders and Materials for Separators Solvay is the only PVDF supplier that uses both emulsion and suspension polymerization technologies, thereby

Brief Review of PVDF Properties and

PVDF membranes can be used as separators in lithium-ion batteries because they have good chemical and heat resistance. Such membranes have good

PVDF-based solid polymer electrolytes for lithium-ion batteries

Unlike liquid electrolytes, which attain high ionic conductivity through the use of high dielectric constant and low-viscosity solvents that promote lithium salt dissociation and ion mobility, solid

Solef® PVDF for Li-Ion Batteries

5 days ago · Solef® PVDF Improves Battery Performance Lithium batteries are a challenging application for most polymeric materials, as they demand long

PVDF Resin for Lithium Electric Binder Market

Feb 25, 2025 · The demand for PVDF (polyvinylidene fluoride) resin in lithium battery binders is propelled by three interconnected factors: the exponential growth of electric vehicles (EVs),

Pvdf For Lithium Ion Battery Market Research Report 2035

Global Pvdf For Lithium Ion Battery Market Research Report: By Grade (High Purity, Industrial Grade, Battery Grade), By Application (Battery Separator, Binder, Electrolyte Additive,

Brief Review of PVDF Properties and

Nov 8, 2022 · PVDF membranes can be used as separators in lithium-ion batteries because they have good chemical and heat resistance. Such

Re-evaluation of battery-grade lithium purity toward

Feb 8, 2024 · Lithium-ion batteries (LIBs) have emerged as prevailing energy storage devices for portable electronics and electric vehicles (EVs) because of their exceptionally high-energy

Design strategies and performance enhancements of PVDF

Among SPEs, poly (vinylidene fluoride) (PVDF)-based solid electrolytes offer excellent thermal stability and mechanical strength, making them highly suitable for high-energy-density flexible

Polymers for Battery Applications—Active

In the light of an ever-increasing energy demand, the rising number of portable applications, the growing market of electric vehicles, and the necessity to store

Polyvinylidene Fluoride (PVDF)

PVDF powder is mainly used as a positive electrode binder and diaphragm coating material in lithium batteries. Firstly, as a positive electrode binder, PVDF can connect positive electrode

Recent advances on battery separators based on poly

Oct 1, 2021 · Lithium-ion batteries represent one of the most suitable systems for effective energy storage for a wide range of applications, such as smartphones, laptops, electric vehicles, or

Enabling high-capacity Li metal battery with PVDF

Jan 1, 2023 · The DMF-Li + complex solvation structure offers the transport path for lithium ions, β-PVDF after dehydrofluorination with a high dielectric constant enhances the dissociation of

PVDF Demand-Supply, Production Capacity,

Sep 21, 2023 · The global PVDF market is expected to reach $4 billion by 2032 with a CAGR of 17%, driven by the increasing adoption of electric vehicles.

PVDF for Lithium-ion Battery Market – PW Consulting Chemical & Energy

Feb 25, 2025 · Regulatory frameworks governing chemical safety, sustainability, and battery performance directly impact the use of polyvinylidene fluoride (PVDF) in lithium-ion batteries.

Top 10 Essential Battery Chemicals for Modern Cell

3 days ago · Introduction: An Overview of Battery Chemicals (Lithium-ion battery packs being assembled using essential battery chemicals like electrolytes and conductive

Poly (vinylidene fluoride) separators for

May 12, 2021 · Lithium-ion battery separators can be classified according to battery types (like liquid batteries and solid-state batteries), materials (like

Binding mechanisms of PVDF in lithium ion batteries

Jul 1, 2021 · The binding mechanism of polyvinylidene fluoride (PVDF) in lithium ion batteries (LIBs) is important for the development of new binders and the peelin

PVDF Binder for Lithium-Ion Batteries | Elcan

What is PVDF powder used for? Polyvinylidene fluoride more commonly known as (PVDF) polymers, are widely used as binders in lithium ion batteries. It can

Lithium-ion Battery Technologies for Grid-scale Renewable Energy Storage

Jun 1, 2025 · Furthermore, this review also delves into current challenges, recent advancements, and evolving structures of lithium-ion batteries. This paper aims to review the recent

Advances and prospects of PVDF based polymer electrolytes

Jan 1, 2022 · Some peculiar modified strategies performed in lithium–sulfur batteries and lithium–oxygen batteries are also included. Finally, this review describes the challenges and

PVDF for Lithium-ion Battery Market Disruption Trends and

May 11, 2025 · The global market for polyvinylidene fluoride (PVDF) used in lithium-ion batteries is experiencing robust growth, driven by the burgeoning electric vehicle (EV) and energy storage

PVDF Binder for Li-Ion Battery Electrodes:

Jan 21, 2025 · The global demand for efficient, high-performance lithium-ion (Li-ion) batteries continues to rise, driven by advancements in electric vehicles

6 FAQs about [Can lithium battery-grade PVDF be used for energy storage ]

Why is PVDF a good material for lithium batteries?

PVDF has stood out in the lithium battery industry and become the preferred material with its advantages such as excellent bonding properties, good dispersibility, chemical stability, flame retardant properties, wide operating temperature range and enhanced battery diaphragm performance.

Are PVDF-based solid-state electrolytes suitable for lithium metal batteries?

Among SPEs, poly (vinylidene fluoride) (PVDF)-based solid electrolytes offer excellent thermal stability and mechanical strength, making them highly suitable for high-energy-density flexible batteries. This review presents recent advances in PVDF-based solid-state electrolytes (SSEs) for stable, high-performance lithium metal batteries (LMBs).

How can PVDF-based lithium separators improve battery performance?

Improving the separator based on the storage and migration of lithium ions can greatly improve the comprehensive performance of batteries and promote the development of lithium industry. The electrochemical performance of LIBs can be improved by developing PVDF-based separators with high efficiency.

Can modifying PVDF improve ion-conducting pathways in advanced lithium metal batteries?

These findings underscore the potential of modifying PVDF to create fast ion-conducting pathways, achieving significant improvements in ionic conductivity, lithium-ion transference, and overall stability in PVDF-based SSEs for advanced lithium metal batteries.

Can PVDF be used as a battery separator?

In addition to being a binder, PVDF can also be used to prepare battery separators. Its high porosity and stable electrochemical properties help to improve the permeability of the diaphragm and the wettability to the electrolyte, thereby enhancing the safety and performance of the battery.

What is the ion transport number of lithium-ion battery with PVDF/HDPE separator?

The ion transport number of lithium-ion battery with PVDF/HDPE separator is 0.495, higher than that with commercial separator (0.33) and pure PVDF separator (0.27). Furthermore, LiCoO 2 /Li batteries assembled with PVDF/HDPE separator exhibit great C-rate and cycling performance.

Industry Information

- Palau big ups uninterruptible power supply

- Flywheel energy storage design for three-network communication base station

- Kupa Outdoor Power Supply

- Energy storage power station system cost

- Bloemfontein new energy battery storage box

- Which energy storage container in Asia is better

- Wholesale 5kw hybrid inverter in Johannesburg

- Photovoltaic glass parallel connection

- What are the power supply methods for communication base stations

- Democratic Republic of Congo Energy Storage Equipment

- Is the output voltage of photovoltaic panels stable

- Factory price 3000w inverters in Namibia

- Outdoor power supply lithium iron phosphate temperature control

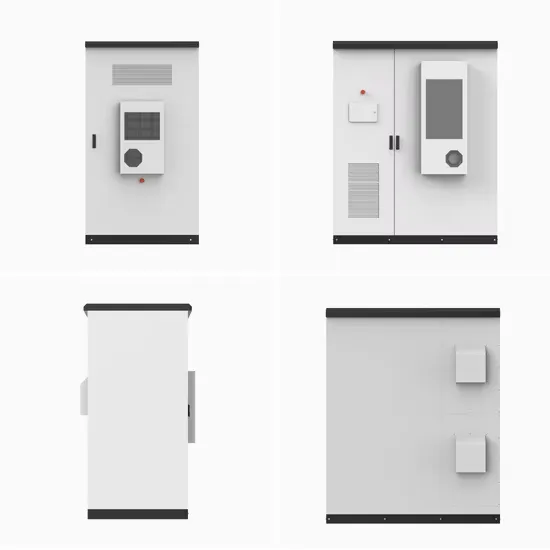

- Charging pile battery cabinet

- Photovoltaic grid-connected and off-grid inverter

- How many watts can a solar light reach

- What inverters are used for photovoltaic energy storage

- Which is the best glass photovoltaic power generation company in Phnom Penh

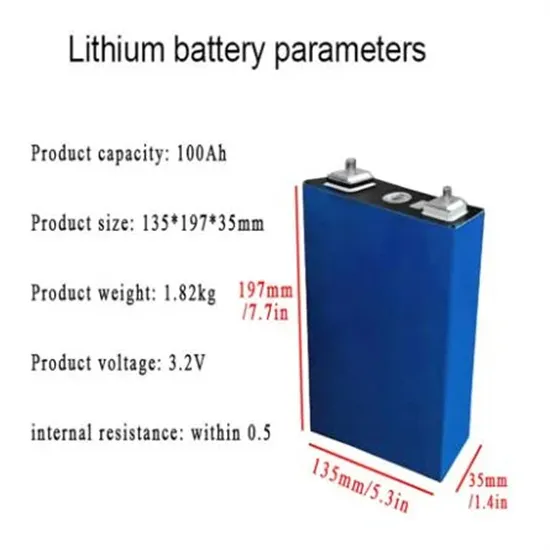

- Energy storage battery single cell capacity

- Which battery cabinet in the Balkan Peninsula has the best value for money

- Electric photovoltaic power station energy storage battery

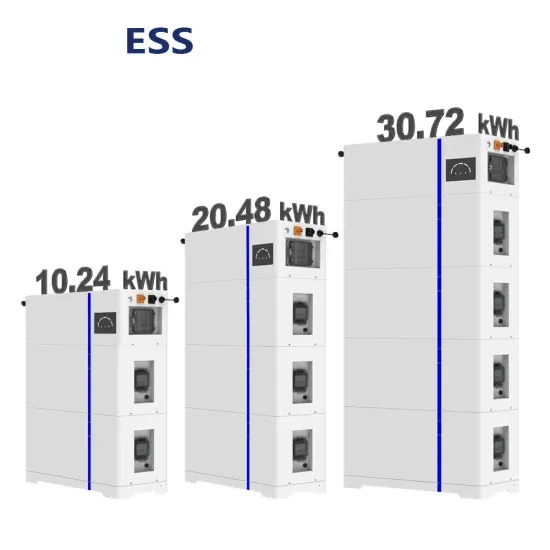

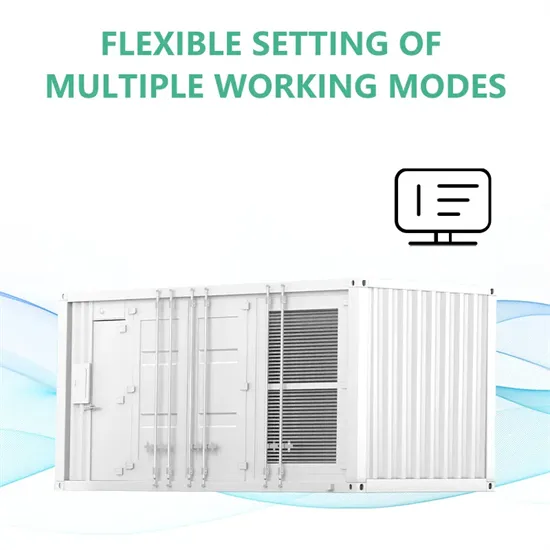

- What does large-scale energy storage mean

- 20kva solar inverter

Commercial & Industrial Solar Storage Market Growth

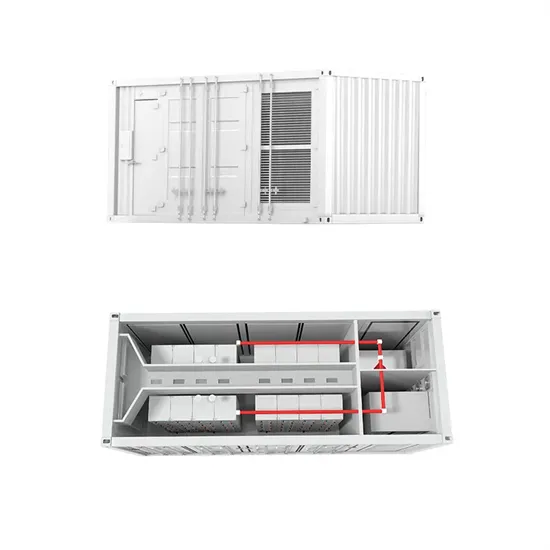

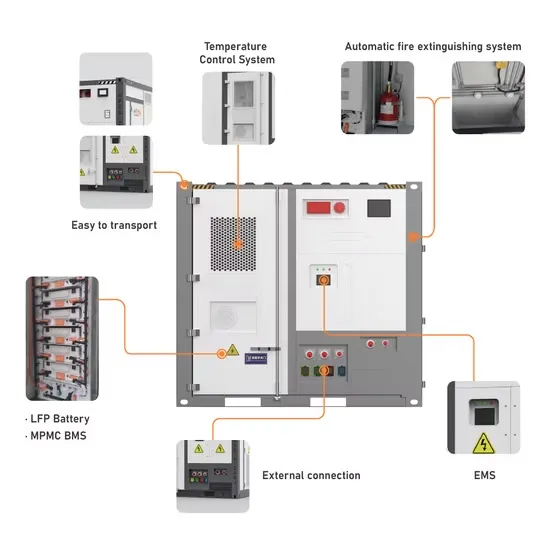

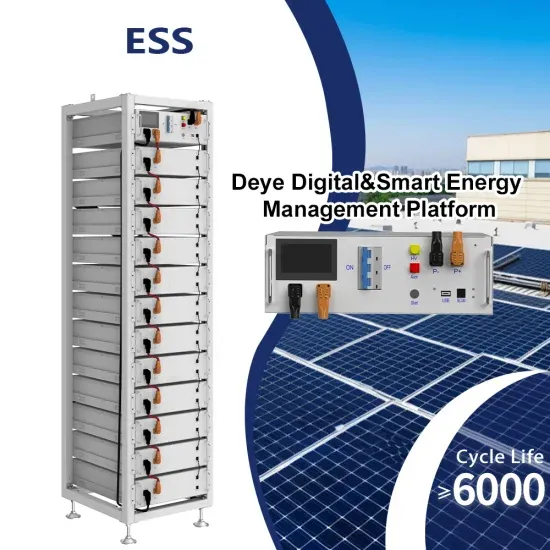

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.