DC System Grounds: Can You Afford to Live with Them?

Feb 28, 2024 · Sources of Grounds DC system grounds can result when a conduction path is formed from either the positive polarity of the system to earth ground or the negative polarity to

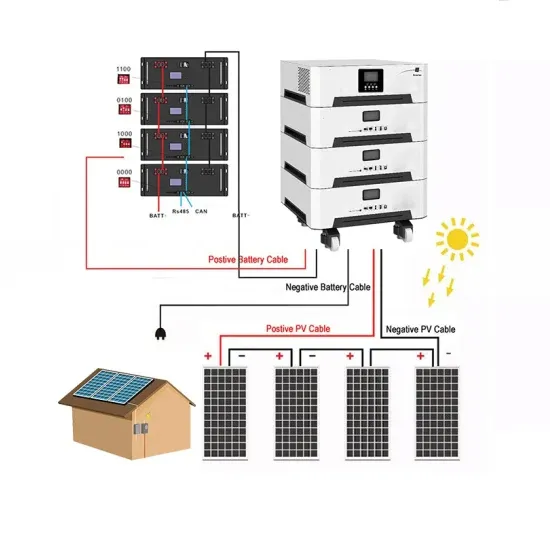

Key Considerations for Installing a Lithium Battery Cabinet

Installing a lithium battery cabinet like Pytes'' V - BOX - OC needs attention to various factors. Space, environment, accessibility, security, foundation, electricals, and ventilation are crucial

Connecting UPS Grounds and Neutrals | EC&M

Oct 1, 2002 · For multiple battery cabinets incorporating battery disconnects, the cabinets are bolted together, forming a single lineup with the UPS. The

U-ENM00044

Feb 3, 2025 · 1 GENERAL DESCRIPTION This manual provides information to authorized service personnel required for proper start-up and maintenance of the UD-100528 Battery cabinet.

Eliminating Electrical Leakage to Ground on Standby Backup Batteries

Feb 15, 2025 · Out of sight, out of mind is a common aphorism, but when it''s applied to standby backup batteries, it can — and does — become catastrophic. Standby battery banks support

U-ENM00044

Feb 3, 2025 · Electric shock may be caused if ground cables from the load devices are not connected. Connect the ground cables to the specified places. Grounding impedance should

When a battery is your power source, what is

Nov 27, 2019 · As a bonus, if you have 2 batteries in series, you can use the middle terminal as ground and have a positive and negative supply from the 2

Understanding and Preventing Battery Ground Faults

Mar 13, 2025 · Understanding and Preventing Battery Ground Faults Our latest IEEE article on Battery Ground Fault Inspection, titled "Continuous Monitoring System and Method for

Ground Fault Detection In The Real World

May 1, 2025 · Placing two (2) battery chargers together onto one (1) battery is a common way to achieve a higher level of redundancy on the dc bus. This configuration also connects two (2)

Battery Cabinet Working Space Front Aisle Floor Loading

Ensure the technique and hardware used in securing the battery cabinet can support the. Direct-current ground-fault detection. Not all battery systems have DC ground-fault detection but

DC battery cabinet grounding requirements and standards

-48 VDC Battery Cabinet Installation and User Manual Mounting the Battery Cabinet • Follow the recommended PPE requirements per the SDS for the battery to be used. (P/N

What happens when laptop is suspended and battery runs out?

Feb 3, 2019 · I would like to know what happens when I have suspended my laptop and then - say 10 hours later battery runs out as suspended state still consumes battery and power was not

Why Can''t You Put A Car Battery On The

Have you ever wondered why you can''t put a car battery on the ground? It seems like it would be easier to just set it down instead of carrying it, but there''s

importance of earthing a rack battery and its

Mar 18, 2023 · So whether your local codes require it or not, it''s safer to ground it than it is to leave it floating. As a side note, different equipment may ground

Connecting the Ground Cable to the Cabinet/Rack

The M6 lug (the end with a larger hole) of the ground cable can be connected to a ground point on the cabinet/rack or a ground bar, depending on the situations in the installation site.

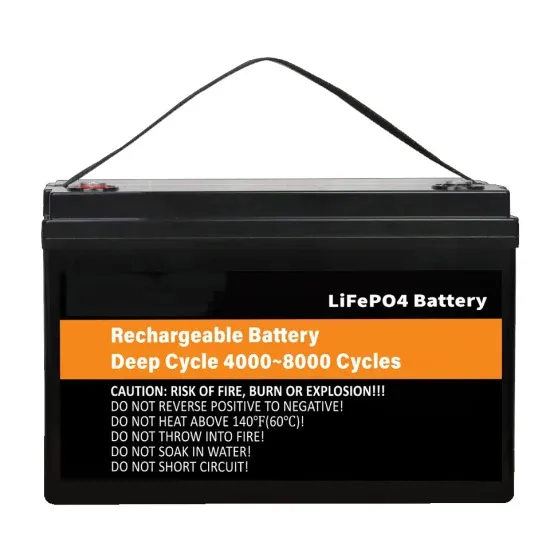

The Ultimate Guide to Battery Charging

Feb 14, 2025 · Lithium-ion batteries power many of our everyday devices, from industrial machinery to personal electronics. However, they also pose

battery report 中 电池状态为suspended是什么意

Jun 18, 2020 · battery report 中 电池状态为suspended是什么意思? 我的surface pro 经常不关机,只关上盖子的情况下一晚上电池电量b就变成0了,导

Why Should Battery Racks Be Grounded? Safety and

Jun 15, 2025 · Battery racks are grounded using copper conductors bonded to the rack structure and connected to a grounding electrode system. Techniques include: 1. Direct bonding to

DC Battery Rack Grounding

Jul 18, 2017 · It''s 125VDC. My usual approach is to include a ground until I can prove that a ground is not useful or is detrimental to the system. I have seen installations done both ways.

Does Putting A Battery On The Ground Kill It?

Mar 28, 2024 · There is a common misconception about batteries, proper battery care, maintenance, and handling. It is commonly believed that putting a

Can 5p batteries be stack mounted? If so, what''s the

When installing more than one IQ Battery there should be at least one foot (300 mm) clearance between the upper battery and the lower battery. And the same distance should also be

Battery Cabinet

Feb 28, 2025 · Contact with any part of a grounded battery can result in electrical shock. The likelihood of such shock can be reduced if such grounds are removed during installation and

Why can t the battery cabinet be grounded

Grounding - Ensure that all batteries are installed in the EG4 battery rack using the mounting hardware provided. Connect a grounding conductor to the grounding lug (or screw) on the rack

How to Properly Ground a Car Battery

Mar 9, 2023 · To ground a car battery, firstly, ensure the engine is switched off and disconnect the negative cable from the battery terminal. Next, use sandpaper to clean up both ends of the

Eaton-Battery-Handbook-BAT11LTA.PDF

Apr 20, 2018 · Improvements in battery technology have been evolutionary rather than revolutionary. Capabilities such as advanced charging regimens, software management for

IFC Mounting Requirements for IQ Battery Systems

Oct 21, 2021 · Enphase IQ Battery 3, 3T, 10, and 10T test was conducted at the manufacturers recommended mounting distances with a minimum of 6" between vertically stacked units, 1"

Ground Detection

May 12, 2020 · The most popular method of ground detection, is to monitor the resistance between the positive and ground as well as between the negative and ground. Ideally this

How To Ground Electrical Enclosure: The

Sep 23, 2021 · Chassis Grounding of Electrical Enclosure This type of ground can be easily observed in a truck or car. Vehicles utilize chassis ground as a

Do I Ground My Battery to Earth for Solar? Essential

Apr 15, 2025 · Yes, you should ground the battery in solar systems. Grounding improves safety, protects against high voltage, and provides lightning protection. Bond all metal parts and

Why are Neutral and Ground Wires Bonded in a

2 days ago · Why Do Neutral and Ground Conductors Need to Be Bonded in the Main Panel? According to NEC Article 250, both the neutral and ground wires

6 FAQs about [Can the suspended battery cabinet be changed to the ground ]

Why do battery energy storage systems need grounding and bonding?

For grid-scale battery energy storage systems (BESS), grounding and bonding is essential for safety and performance. The goal of grounding and bonding is to achieve customer-targeted resistance levels. These low resistance levels allow fault currents to easily discharge into the ground, protecting people, equipment and the BESS itself.

Should substation DC battery rack metals be bonding/grounding to the substation ground grid?

One: Substation DC battery rack metals should be better without bonding/grounding to the substation ground grid, because during the fault the substation area elevate on potentials so the grounding may affect the battery functionality.

Does a negative grounded battery system provide a local bonding?

Wayne, as you stated, using a negative grounded battery system appears to provide a "local" bonding - however, in backup mode, it is the only bonding that occurs (the mains are disconnected). Caveat needed!!

Should the negative terminal of the battery be bonded to the rack?

Secondly, if the negative terminal of the battery is bonded to the rack, the rack should be separately earthed and not through the sub station ground grid. Ur fear of ONE, will occur if done other wise. Dickson. There is peace in silence and achievement in plans.

Are grid battery systems at risk?

A recent six-year audit by Clean Energy Associates found that over 25% of grid battery systems had manufacturing defects, putting them at high risk in these areas. The most common causes of defects were quality control issues from the assembly and installation of integrated systems, such as the grounding and bonding components.

How many battery grounds does a floating battery system need?

• At a minimum, a floating battery system requires at least two battery grounds before misoperation can occur. Environmentally Friendly and Clean Power Rooms. Why do we search for grounds? Combined battery ground resistance can become so low that high voltage circuit breaker control schemes are unable to open or close breakers when required.

Industry Information

- Luxembourg household energy storage installation data

- Royu circuit breaker factory in Uganda

- Container 5G base station infrastructure

- Factory price solar powerbox in Czech-Republic

- Sanbian Technology and Photovoltaic Inverter

- Uninterruptible power supply for Aarhus mine in Denmark

- 12v amorphous 820 inverter

- 50kw sunsynk inverter factory in Monaco

- Modular UPS uninterruptible power supply in Ethiopia

- Outdoor Power Camping Small

- Huawei South Tarawa Lithium Battery Energy Storage

- Energy storage power supply OEM customization

- Poland Krakow heavy industry energy storage cabinet manufacturer

- Price of 265w photovoltaic panel

- Dc to ac inverter 12v

- Sophia n150 energy storage power supply

- Methods for expanding photovoltaic containers

- China China portable power station Seller

- Somali Communications Photovoltaic Base Station Address

- Construction of wind power equipment and facilities for communication base stations

- 12V inverter continuous power

- Modern Battery Cabinet Series

- Wholesale 2 breaker sub panel in Bangkok

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.