Inverter Specifications and Data Sheet

2 days ago · For inverters designed for residential use, the output voltage is 120 V or 240 V at 60 Hz for North America. It is 230 V at 50 Hz for many other

How Inverter Systems Work for Beginners

Jan 11, 2022 · The inverter systems and their ability to switch between DC and AC makes them incredibly useful, especially when you''re on the go and need

Voltage Source Inverter Design Guide (Rev. B)

Aug 25, 2017 · Voltage source inverters (VSI) are commonly used in uninterruptible power supplies (UPS) to generate a regulated AC voltage at the output. Control design of such

Introduction to Inverters

Jul 23, 2025 · Microcontroller A microcontroller is also known as Digital Signal Processor. This is the core of the inverter that is responsible for managing the

How to tune PI controller for grid connected

May 17, 2017 · The PI controller must be employed for the outer voltage loop, and the PR controller for the inner current loop. Apply manual tuning, by following

Understanding Voltage Controlled Oscillators

Jan 26, 2021 · Voltage controlled oscillators vary their output frequency proportional to an input voltage and find use in PLLs, radar, communications,

6.4. Inverters: principle of operation and

The three most common types of inverters made for powering AC loads include: (1) pure sine wave inverter (for general applications), (2) modified square

Growatt settings fine tuning

Dec 29, 2020 · Hi all, New to the forum so please go easy . I''ll try to be detailed enough and hopefully this thread assists many others with the same intention.

4. Configuration

Nov 2, 2022 · The inverter is ready for use with the standard factory settings (see the Technical specifications chapter). The inverter can be configured using the VictronConnect app. Connect

Decoding Inverter Parameters (Part I)

Jan 25, 2025 · In previous editions, we discussed two critical indicators on the PV side of an inverter: the maximum over-sizing ratio and the maximum PV input

What Does An Inverter Do? Complete Guide To

Jul 8, 2025 · Learn what inverters do, how they convert DC to AC power, types available, and applications. Complete guide with sizing tips, safety advice, and

How to Adjust Voltage Regulator: A

6. Fine-Tuning the Voltage Regulator If the output voltage is not within the desired range, further fine-tuning may be necessary. Some voltage regulators have

Changing inverter voltage output?

Aug 8, 2020 · Outback 3648 default setting is 120 volts. I got carried away building my own whacha-ma-callit (shop I guess). Even with sub-stations the wire runs are often quite long. It is

Voltage Source Inverter Design Guide (Rev. B)

Aug 25, 2017 · 1 Design Overview Voltage source inverters (VSI) are commonly used in uninterruptible power supplies (UPS) to generate a regulated AC voltage at the output. Control

General Inverter Troubleshooting | Magnum Dimensions

4 days ago · General Inverter Troubleshooting The following is a quick reference for Magnum Energy inverter/charger to diagnose typical symptoms. Always refer to your full user manual.

Guide to Frequency Inverters: Optimizing Motor

Nov 13, 2024 · By keeping these considerations in mind, you can maximize the benefits of using frequency inverters in your motor systems. Whether you''re

Grid-connected PV inverter system control optimization

Aug 7, 2025 · In this study, a 3-phase voltage source inverter (VSI) is used in the grid-tied photovoltaic system depicted in Fig. 1 and its corresponding simulation in Fig. 2. The PV array,

What is equation for inverter output voltage?

I am confused to select the value of DC input to have some specific value of output voltage. Please suggest possible solution or voltage equation for inverters.

inverters

A function that has the inverter automatically compensate for the output voltage to the motor even if the incoming voltage fluctuates. It is useful as a preventive measure against low output

How does an inverter control current?

Oct 26, 2021 · The two go hand-in-hand. If, on average, you''re providing slightly more current than the load sinks, the voltage will be increasing as you charge the output capacitance, since

Electrical Tutorial

The electronic circuitry does create the proper frequency and voltage levels that make up the waveform of the output current so while the inverter doesn''t really

Power Inverters Explained

Apr 25, 2020 · FREE COURSE!! Learn the basic working principle of power inverters, how they work, why we use them, where we use them and their

Understanding inverter voltage

Jan 10, 2024 · The inverter output inverter voltage is a critical aspect that must align with the standard alternating current (AC) voltage required by connected devices. The quality of the

Tuning Inverter Behavior through Threshold Voltage

Aug 18, 2025 · The figures for the inverter gain as a result of fine-tuning both n- and p-type threshold voltages are the highest ever attained in organic semiconductor inverters. We have

Investigation of the modulation index tuning advantages

6 days ago · This paper demonstrates that the possibility to regulate the modulation index of the Pulse-Width Modulation (PWM) scheme by adjusting the DC bus voltage could improve the

Voltage Control Using Inverter Reactive Power

Dec 20, 2023 · During relatively low levels of real power output, the inverter operates at zero reactive power (or power factor equal to 1.0), and the power

How Does a Frequency Inverter Work?

Dec 13, 2023 · For example, in the control of high-voltage inverters, two strategies of time segmentation control and phase shift control have been

What does the inverter voltage specifications represent?

Aug 17, 2025 · This is the inverter''s AC range (relating to its nominal output). Since grid voltage fluctuates constantly, the inverter has to adjust to that voltage within a given window. For

Advanced Inverter Drive Parameter Settings

Mar 9, 2025 · Inverter drives are essential for industrial automation, providing precise motor control, energy efficiency, and system flexibility. While basic

What Is MPPT Solar Inverter? Maximize Solar

Jun 13, 2024 · An MPPT solar inverter optimizes solar panel output by tracking the maximum power point to deliver maximum possible current to your solar

Parameters

Jun 6, 2025 · Motor Parameters The parameters to adjust the inverter to the motor are boost, fweak, fslipmin, fslipmax, polepairs, fmin, fmax and numimp. They can be deduced from the

6 FAQs about [Does the inverter output have fine-tuning voltage ]

What voltage does an inverter use?

In different countries, the applicable AC voltage is different, and most countries use 110v, 120v output inverter voltage. You can confirm on the search engine or see how much AC voltage the home appliance label uses. How can the quality of inverter output voltage be measured?

What is an example of a power inverter?

Common examples are refrigerators, air-conditioning units, and pumps. AC output voltage This value indicates to which utility voltages the inverter can connect. For inverters designed for residential use, the output voltage is 120 V or 240 V at 60 Hz for North America. It is 230 V at 50 Hz for many other countries.

What are the features of a given inverter design?

We can identify six features of a given inverter design which we can use to evaluate it and compare it to other designs. They are: The logic levels are found by insisting that VHI and VLO are such that VHI applied to the input of an inverter results in an output of VLO, and that VLO applied to the input of an inverter results in an output of VHI.

What is voltage source inverter (VSI)?

Voltage source inverters (VSI) are commonly used in uninterruptible power supplies (UPS) to generate a regulated AC voltage at the output. Control design of such inverter is challenging because of the unknown nature of load that can be connected to the output of the inverter.

How does a sine wave inverter work?

The inverter outputs a pulsed voltage, and the pulses are smoothed by the motor coil so that a sine wave current flows to the motor to control the speed and torque of the motor. The voltage output from the inverter is in pulse form. The pulses are smoothed by the motor coil, and a sine wave current flows.

When does a DC inverter start?

The inverter starts as soon as the DC bus voltage is present at a greater level than 10% of the AC maximum. Observe the controlled AC voltage waveform on the output. The frequency and the amplitude of the AC voltage is determined by the values on the powerSUITE page of the solution.

Industry Information

- New energy storage investment enterprises

- How much does a base station energy storage power supply cost

- Port Vila home energy storage power supplier

- 12v inverter is the simplest

- Chad containerized generator sets

- Wholesale switchgear controls in Nigeria

- What brands of inverters are available for small mobile energy storage sites

- 240v circuit breaker in China in Senegal

- Berlin Photovoltaic Glass House Private

- Solar 50W Price

- Bangkok New Energy Storage Entrepreneurs Tour

- North Macedonia High Temperature Solar System

- Base station power system cabinet mainly includes

- Flexible photovoltaic panel components

- Castries Station Energy Storage System

- Mauritania industrial UPS uninterruptible power supply

- Israel lithium battery station cabinet custom manufacturer

- Single row battery rack container base station

- Solar container energy storage power generation system

- Gambia installs photovoltaic panels in containers

- How is the price of supercapacitors

- Smart photovoltaics help communication base stations

- Dubai all-vanadium liquid flow energy storage battery

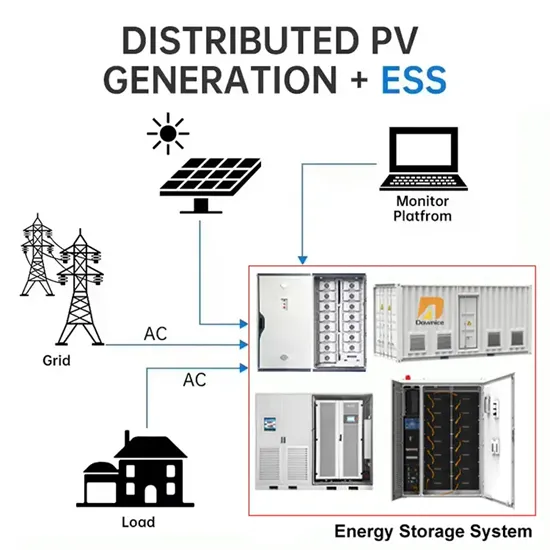

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.