BATTERY MODULE AND PACK ASSEMBLY PROCESS

The battery production department focuses on battery production technology. Member companies supply machines, plants, machine components, tools and services in the entire process chain

The Nordic Battery Value Chain

Feb 24, 2023 · This report maps out the Nordic battery value chain and highlights key necessities of the Nordic ecosystem on how to grasp the opportunity of sustainable batteries

Key Points of Lithium Battery PACK

Jun 27, 2024 · The lithium-ion battery pack manufacturing process involves selecting and matching battery cells, assembling the pack with a protective

nPM1100

Discover the nPM1100 Power Management IC (PMIC) – Optimize your Nordic nRF52® and nRF53® SoCs with dual-mode buck regulation, integrated

(PDF) Lithium-ion Battery Cell Production

Feb 6, 2019 · Abstract The first brochure on the topic "Production process of a lithium-ion battery cell" is dedicated to the production process of the lithium

Battery Module: Manufacturing, Assembly and

Dec 28, 2022 · In the Previous article, we saw the first three parts of the Battery Pack Manufacturing process: Electrode Manufacturing, Cell Assembly, Cell

Top 10 Companies in the Europe Lithium-ion Battery

Jun 10, 2025 · The Europe Lithium-ion Battery Recycling Market was valued at US$ 1.85 Billion in 2024 and is projected to reach US$ 4.25 Billion by 2030, growing at a Compound Annual

PRODUCTION PROCESS OF A LITHIUM-ION BATTERY CELL

Feb 7, 2024 · The manufacture of the lithium-ion battery cell comprises the three main process steps of electrode manufacturing, cell assembly and cell finishing. The electrode

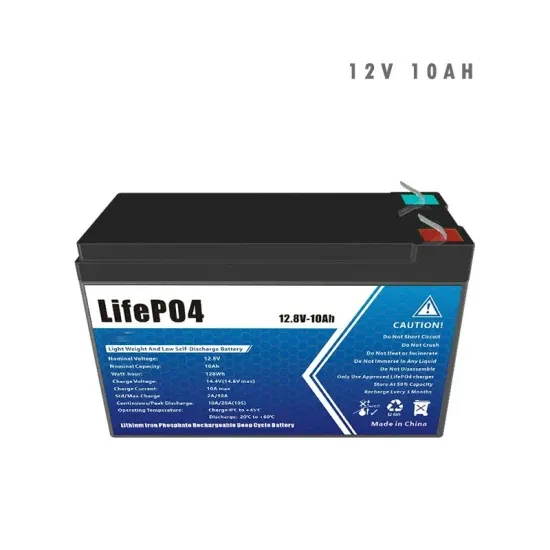

LiFePO4-batterier for Industri, Hjem & Fritid

123SmartBMS gen3 er enkel, funksjonsrik, modulær og kostnadseffektiv BMS for å holde litium-banken din i god stand over lang tid. BMS-en måler viktige data

LiFePO4-batterier for Industri, Hjem & Fritid

Komplette lithium-løsninger: LiFePO4-celler, BMS, batteripakker og tilbehør for båt, hus og industri. Kvalitetssikrede produkter til konkurransedyktige priser.

FULL REPORT THE NORDIC BATTERY VALUE CHAIN

How does a lithium-ion battery cell estimate residual energy? When the discharge process continues, the terminal voltage decreases and converges back to the discharge voltage. The

Battery Boom: Global Gigafactories on the Rise

Sep 18, 2024 · Chemical giant Chemours has opened a battery innovation complex in Newark, Delaware, where engineers will test next-generation

Nordic lithium battery pack processing

Hydrovolt has the capacity to process 12 000 metric tons of battery packs on annual basis, or enough to recycle the entirety of the Norwegian end-of-life battery market. The fully automated

NIB finances Northvolt battery production and recycling in

Jan 16, 2024 · NIB has granted a 11-year USD 97.3 million (EUR 88.30 million) loan to Northvolt Ett AB, as part of a consortium, for the development, construction, operation and maintenance

Direct recycling of Li-ion batteries from cell to

Direct recycling is a novel approach to overcoming the drawbacks of conventional lithium-ion battery (LIB) recycling processes and has gained considerable

Production & Recycling of EV Batteries

Feb 12, 2024 · The electrode and battery manufacturers are closely collaborating with research institutions such as VTT, RISE, SINTEF, IFE and DTI, as well as universities across the Nordic

Lithium Battery Pack Assembly: A

May 6, 2024 · Quality control is a cornerstone of the lithium battery pack assembly process. At every stage, inline testing and inspection stations

How are Lithium-ion Battery Packs Manufactured?

Discover the step-by-step process of lithium-ion battery packs manufacturing and learn how these essential components are made. Read the full guide now!

Advanced lithium-ion battery process manufacturing

Jul 18, 2025 · Festo offers high-precision automation components for battery manufacturing with pneumatic and electric actuators, valves, and handling systems to improve electrode coating,

Energy Storage Nordic Lithium Battery Pack Replacement

A lithium-ion battery pack, also known as a battery module, is a manufacturing process for lithium-ion batteries. It involves connecting multiple lithium-ion cells in series and parallel

Business Norway

Norway: your partner in developing the battery value chain Norway is home to a circular battery ecosystem encompassing expert raw materials processing and

Understanding the Lithium-Ion Battery Manufacturing Process

Aug 5, 2025 · This means that during the battery''s operation, lithium ions move from the anode to the cathode through an electrolyte, and then back again when charging. The efficiency of this

Home

We design and manufacture battery packs tailored to your machines. Whether you need a specific shape, voltage, or performance profile, we build the right

Production & Recycling of EV Batteries

Feb 12, 2024 · Fortum''s recycling process combines mechanical and low-CO hydrometallurgical technologies to recover critical metals from EOL lithium-ion batteries, as well as battery

Lithium-Ion Battery Pack Manufacturing Process

Jun 4, 2025 · Conclusion The process of lithium-ion battery pack manufacturing involves meticulous steps from cell sorting to final testing and assembly. Each

Optimizing Lithium-Ion Battery Pack Line

Oct 22, 2024 · The lithium battery manufacturing process requires highly reliable, stable, and precise equipment for process control. It also demands intelligent

PRODUCTION PROCESS OF A LITHIUM-ION

Apr 19, 2023 · Cost‐savings in lithium‐ion battery production are crucial for promoting widespread adoption of Battery Electric Vehicles and achieving

The Nordic Battery Value Chain

Feb 24, 2023 · Background There is an emerging battery industry in Sweden, Finland, and Norway, with the business and employment potential to become a new basic industry. The

Lithium battery Nordic

This article is part of a series dealing with building best-in-class lithium battery systems from bare cells, primarily for marine use, but a lot of this material finds relevance for low-voltage off-grid

The ABC of the battery industry

Mar 10, 2023 · The Nordic Battery Belt creates a logistics chain and a cooperation network of operators within the Nordic battery value chain. The countries''

Production & Recycling of EV Batteries

Feb 12, 2024 · This section provides background information for this study. It includes a description of the structure of batteries and introduces some of the technical terms used

Recycling lithium-ion batteries from electric vehicles

Nov 6, 2019 · Processes for dismantling and recycling lithium-ion battery packs from scrap electric vehicles are outlined.

Its world record in electric cars is creating a

Jul 18, 2022 · The fully automated recycling process enables recycling of up to 95 per cent of battery materials, including aluminium and the "black mass"

Norway''s maturing battery industry embraces green energy

May 8, 2023 · Whether for EVs or energy storage, Norway has always had ideal conditions for battery growth: renewable energy in the form of hydropower, strong government financial

Lithium-ion Battery Pack Manufacturing Process

Jul 28, 2023 · In this article, we will explore the world of battery packs, including how engineers evaluate and design custom solutions, the step-by-step

6 FAQs about [Nordic lithium battery pack processing]

What does Nordic batteries do?

We develop battery modules, racks and energy storage systems designed to power industrial applications across challenging sectors, including construction, maritime, defence, and grid systems. At Nordic Batteries we focus on what is important: safety, reliability and performance.

What is the Nordic battery collaboration?

The Nordic Battery Collaboration is a key initiative. The decision to carry out this report was taken by Business Sweden, Business Finland, Innovation Norway and the Swedish Energy Agency together. All parties are financing the report. The report is conducted by Business Sweden.

What is the packaging and Assembly of lithium-ion battery packs?

The packaging and assembly of lithium-ion battery packs are crucial in the field of energy storage and have a significant impact on applications like electric vehicles and electronics. The pack line process consists of three main phases: production, assembly, and packaging.

Are Nordic batteries looking for a development engineer?

Nordic Batteries are seeking a development engineer for mechanical construction and system design. Factor 47 is operative! The pilot line where Nordic Batteries will produce their first battery modules is now officially open after the visit from former Prime Minister Erna Solberg where she cut the banner to kick it off.

What is a lithium ion battery pack?

A battery pack consists of multiple cells connected in series or parallel. How to make lithium-ion batteries? It’s always been an interesting topic. The production of lithium-ion batteries is a complex process, totaling Three steps. The cell sorting stage is a critical step in ensuring the consistent performance of lithium-ion batteries.

What is the Nordic battery value chain?

The battery value chain builds upon Nordic traditional strongholds such as automotive, maritime, chemicals, manufacturing and mining. Actors within the Nordic battery ecosystem are active on global markets with strong ambitions and devotion to sustainability.

Industry Information

- Factory price furnace breaker in Pretoria

- Vientiane Chemical Energy Storage Project

- 200kw lithium battery energy storage system inverter in the United States

- Battery Cabinets and Energy Storage Systems

- Which countries have wind and solar complementary communication base stations in Kazakhstan

- Jerusalem Energy Storage Equipment

- Tool battery wh

- El Salvador Integrated Energy Storage Battery Company

- Communication with base station is abnormal

- China s communication base station lithium-ion battery 372KWh

- Mobile energy storage price

- Kabul zero carbon energy storage battery manufacturer

- Xia Energy Group 5g base station

- Northern Cyprus Container BESS Wholesale

- Lithium iron battery 5g energy storage base station

- What is geomagnetic energy storage battery

- Germany power tool lithium battery

- How to cool down the new energy battery cabinet

- Huanqi Outdoor Power Supply BESS

- Nicosia Industrial UPS Uninterruptible Power Supply Brand

- Huawei Energy Storage Container Engineering Vehicle

- 700W solar panel size

- Can the photovoltaic off-grid system be used during a power outage

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.