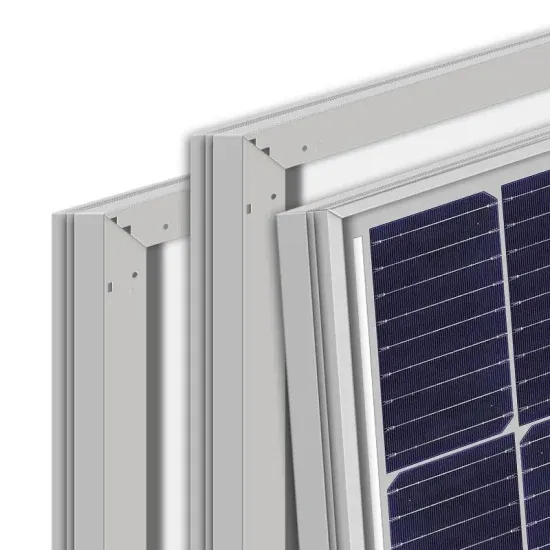

PV Solar Panels Silk® Premium 500w

Discover our new product: PV Panels Silk® Premium 490-510 Wp Monocrystalline 150 1/3 cut MBB cells. Contact Futurasun now for a quotation.

Monocrystalline silicon photovoltaic panel specifications

Monocrystalline solar panels are produced from one large silicon block in silicon wafer formats. The manufacturing process involves cutting individual wafers of silicon that can be

Techno-economic performance comparison of crystalline and thin film PV

Oct 1, 2020 · This investigation compares the financial performance of three different photovoltaic (PV) panel technologies, namely, monocrystalline, polycrystalline and thin film copper indium

Holistic Assessment of Monocrystalline Silicon (mono-Si) Solar Panels

Jun 16, 2023 · With the rising demand for lower carbon energy technologies to combat global warming, the market for solar photovoltaics (PVs) has grown significantly. Inevitab.

Utility scale solar PV OVERVIEW

Jan 9, 2023 · AFEA POWER will utilise the most commercially operable types of solar panels to convert the solar energy into electricity. These photovoltaic (PV) technologies include

sunhero

Discover the differences between monocrystalline and polycrystalline solar panels, including their efficiency, appearance, and suitability for various applications.

Monocrystalline vs Polycrystalline

Aug 12, 2024 · A monocrystalline solar panel is a common solar panel type widely used in residential and commercial photovoltaic (PV) systems.

The difference between monocrystalline silicon

May 24, 2024 · The magical silicon wafer that converts solar energy into electrical energy is the core of photovoltaic technology. Today, let''s take a closer look at

Monocrystalline photovoltaic panels: what they are and their

Dec 11, 2024 · Monocrystalline photovoltaic panels are advanced devices designed to convert sunlight into electrical energy through a process called the photovoltaic effect. Their

What Is a Monocrystalline Solar Panel?

Aug 4, 2024 · Monocrystalline solar panels, known as mono panels, are a highly popular choice for capturing solar energy, particularly for residential

Monocrystalline silicon solar energy specifications

alline solar panels deliver a higher efficiency Monocrystalline solar panels are one of the most popular choices for h. meowners looking to take advantage of solar energy. Monocrystalline

Monocrystalline Silicon PV: 5 Advantages Over Alternatives

Jun 30, 2025 · Monocrystalline silicon PV offers 22-26% efficiency (vs 15-18% for polycrystalline), 25-year lifespan with <0.5% annual degradation. Its low-light performance generates 10%

Advancements in photovoltaic technology: A comprehensive

Apr 1, 2025 · Abstract Photovoltaic (PV) technology has become a cornerstone in the global transition to renewable energy. This review provides a comprehensive analysis of recent

Overview of life cycle assessment of recycling end-of-life photovoltaic

Jan 1, 2024 · Crystalline silicon (C–Si) photovoltaic (PV) modules are currently reaching the End-of-life (EOL) stage, and the environmental impact of recycling PV is of great concern. The life

Life Cycle Greenhouse Gas Emissions of

Mar 19, 2012 · As the names suggest, monocrystalline silicon (mono-Si) PV cells are made from wafers cut from an ingot of single crystalline silicon and

Solar Panel

Oct 16, 2023 · Monocrystalline solar panels are made from single-crystal silicon, resulting in their distinctive dark black hue. This uniform structure, with fewer

Performance analysis of mono crystalline, poly crystalline and

Dec 1, 2021 · PV materials fall into three categories: crystallized silicon, thin film technology, and new emerging technologies as shown in Fig. 1 (a). Silicon is one of the most prevalent

Monocrystalline silicon: efficiency and

Sep 3, 2018 · Monocrystalline silicon is used to manufacture high-performance photovoltaic panels. The quality requirements for monocrystalline solar panels

Monocrystalline silicon photovoltaic panel specifications

This Renogy 550W Monocrystalline Solar Panel maximizes power output while minimizing installation space and system equipment costs, primarily used for utility-scale systems, solar

Monocrystalline Solar Panels: A Comprehensive

A monocrystalline solar panel is a type of photovoltaic (PV) panel made from a single continuous crystal structure of silicon. This manufacturing process gives

Comparison Between Monocrystalline Silicon Photovoltaic Panels

The photovoltaic conversion efficiency of monocrystalline silicon solar panels is generally higher than that of polycrystalline silicon panels, with top-tier monocrystalline panels achieving

Monocrystalline Solar Panels: Advantages and

Good silicon feedstock is expensive (although less so in 2010 then it has been for a a while) and the cost of making a single pure crystal is time-comsuming and

Monocrystalline Solar PV Panels

How Monocrystalline Panels Work: Monocrystalline solar panels are made from single-crystal silicon ingots, which are produced by melting high-purity silicon

Status and perspectives of crystalline silicon photovoltaics in

Mar 7, 2022 · Crystalline silicon solar cells are today''s main photovoltaic technology, enabling the production of electricity with minimal carbon emissions and at an unprecedented low cost. This

Monocrystalline, Polycrystalline, and Thin-Film

3 days ago · Thin-film panels are constructed from ultra-thin layers of photovoltaic materials, such as cadmium telluride or amorphous silicon, deposited onto a

Socio-Economic and Environmental Impacts of Silicon Based Photovoltaic

Jan 1, 2013 · Recycling of PV panel is currently not economically viable because waste volumes generated are too small; significant volumes of end-of-life photovoltaic panels will begin to

Monocrystalline silicon solar cells applied in photovoltaic

Sep 19, 2013 · Purpose: The aim of the paper is to fabricate the monocrystalline silicon solar cells using the conventional technology by means of screen printing process and to make of them

Comparative Analysis of Conversion Efficiency of Various Solar Panels

Jan 5, 2023 · Considering factors such as conversion efficiency of solar panels, technical level, maturity of production process, market share, etc., for large-scale grid-connected photovoltaic

Enhancement of efficiency in monocrystalline silicon

Sep 6, 2024 · As the representative of the first generation of solar cells, crystalline silicon solar cells still dominate the photovoltaic market, including monocrystalline and polycrystalline

Module

"First-generation PV" refers to crystalline silicon PV technology, of which the two most common types are monocrystalline silicon PV cells (mono c-Si) and

Crystalline Silicon Photovoltaics Research

3 days ago · The U.S. Department of Energy (DOE) Solar Energy Technologies Office (SETO) supports crystalline silicon photovoltaic (PV) research and

Monocrystalline silicon photovoltaic panel specifications

Unlike monocrystalline and polycrystalline solar panels, thin-film solar panels are manufactured using photovoltaic substances which include Amorphous silicon (a-Si), copper

What kind of silicon is used in solar photovoltaic

Jun 19, 2024 · Silicon is primarily categorized into three types utilized in solar photovoltaic panels: monocrystalline silicon, polycrystalline silicon, and

[Comparison] Monocrystalline vs Polycrystalline

Jul 28, 2020 · Solar panel technology has dramatically improved over the years, and a range of innovative solar panels are now being introduced in the

Environmental impact assessment of monocrystalline silicon

Jan 20, 2016 · Life cycle assessment on monocrystalline silicon (mono-Si) solar photovoltaic (PV) cell production in China is performed in the present study, aiming to evaluate the

6 FAQs about [Photovoltaic panel monocrystalline silicon scale]

What is the efficiency of a monocrystalline photovoltaic (PV) panel?

With an efficiency rate of up to 25%, monocrystalline panels reach higher efficiency levels than both polycrystalline (13-16%) and thin-film (7-18%) panels. Monocrystalline photovoltaic (PV) cells are made from a single crystal of highly pure silicon, generally crystalline silicon (c-Si).

Is a monocrystalline solar panel a photovoltaic module?

Yes, a monocrystalline solar panel is a photovoltaic module. Photovoltaic (PV) modules are made from semiconducting materials that convert sunlight into electrical energy. Monocrystalline solar panels are a type of photovoltaic module that use a single crystal high purity silicon cell to harness solar power.

Why is monocrystalline silicon used in solar panels?

Monocrystalline silicon is used to manufacture high-performance photovoltaic panels. The quality requirements for monocrystalline solar panels are not very demanding. In this type of boards the demands on structural imperfections are less high compared to microelectronics applications. For this reason, lower quality silicon is used.

What is a monocrystalline photovoltaic (PV) cell?

Monocrystalline photovoltaic (PV) cells are made from a single crystal of highly pure silicon, generally crystalline silicon (c-Si). Monocrystalline cells were first developed in the 1950s as first-generation solar cells. The process for making monocrystalline is called the Czochralski process and dates back to 1916.

What is the difference between monocrystalline and polycrystalline solar panels?

Monocrystalline solar panels are distinguished by their high efficiency rates, ranging from 15% to 25%. In comparison, polycrystalline solar panels have lower efficiency rates, typically between 13% and 16%. Power Rating: The power rating, quantified in watts (W), is a critical factor affecting the cost of monocrystalline solar panels.

How are monocrystalline panels made?

The manufacturing process for monocrystalline panels begins with melting raw silicon, which is then used to grow a single crystal silicon ingot (block of solid silicon) following a process called the Czochralski method, so named for the Polish chemist who discovered it.

Industry Information

- Energy storage project capacity standards

- How much does the Portonovo BESS portable power supply cost

- Sungrow brand inverter manufacturers

- Outdoor power supply wmt

- London base station photovoltaic energy storage

- 90v photovoltaic thin film module

- Annual power generation of wind solar and energy storage in Baghdad

- Mobile Wireless Outdoor Base Station

- Honiara Energy Storage Container Power Plant Operation

- How to recruit energy storage container photovoltaic solar energy

- Ankara Solar Water Pump Factory

- How much does photovoltaic energy storage cost

- French portable energy storage battery company

- Production of graphene energy storage batteries

- Tunisia inverter grid connection standard

- Skopje Mobile Photovoltaic Folding Container Wholesale

- Details of the positive outdoor power supply

- What are the industrial energy storage devices in Shanghai

- China wholesale rv circuit breaker producer

- Solar powered mobile container power supply principle

- How to use the battery of communication base station

- How to distinguish battery cabinets and power cabinets

- How many watts does an off-grid inverter carry

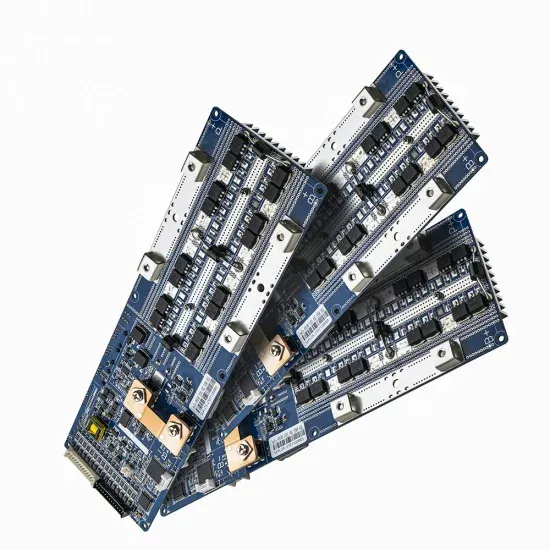

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.