ISO Certifications for Battery Manufacturing

Dec 23, 2024 · Introduction to ISO Standards for Battery Manufacturing Battery manufacturing is an industry at the forefront of innovation, driven by the global

BATTERY PRODUCTION OF THE FUTURE

Jan 2, 2025 · This applies regardless of the sector and relates to areas including consumer electronics, stationary energy storage, e-scooters and e-bikes, commercial vehicles or

How to ensure battery quality in battery

Jan 12, 2024 · For any energy storage battery supplier, control of the production process and battery quality is crucial in battery production. A good battery is

Challenges And Solutions In High-Quality Battery Production

Mar 20, 2025 · Manufacturers must focus on two primary aspects of battery quality: defect rates and conformance to design specifications. Defects, even those on a microscopic level, can

Empowering lithium-ion battery manufacturing with big

Dec 15, 2024 · Abstract With the rapid development of new energy vehicles and electrochemical energy storage, the demand for lithium-ion batteries has witnessed a significant surge. The

HANDBOOK FOR ENERGY STORAGE SYSTEMS

ABOUT THE ENERGY MARKET AUTHORITY The Energy Market Authority ("EMA") is a statutory board under the Ministry of Trade and Industry. Our main goals are to ensure a

Early Quality Classification and Prediction of Battery Cycle

Jun 1, 2022 · An accurate determination of the product quality is one of the key challenges in lithium-ion battery (LIB) production. Since LIBs are complex, electro

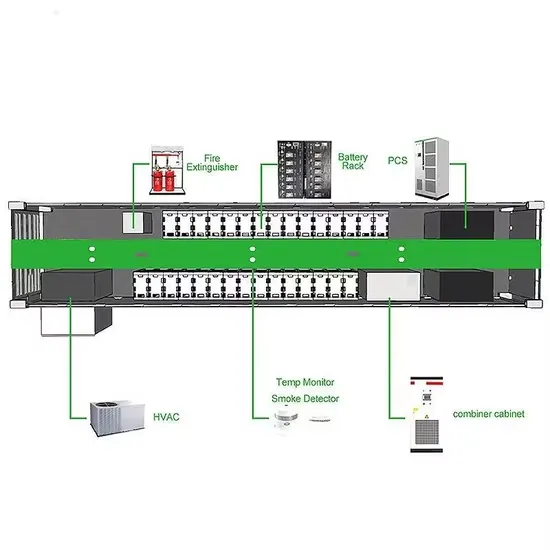

EDAG Optimizes Battery Energy Storage System Production

Jan 27, 2025 · Blueprint of flexible, scalable BESS production (source: EDAG PS) Based on the BESS concept study, EDAG PS has developed a blueprint for the production of battery energy

Quality Requirements for Battery Energy Storage

Jan 8, 2025 · The purpose of this quality requirements specification (QRS) is to specify quality management requirements and the proposed extent of purchaser intervention activities for the

Energy Storage & Conversion Manufacturing

Aug 31, 2023 · Machine level – creating new manufacturing machinery and improving existing equipment to enhance accuracy and throughput in order to lower the cost of energy storage

Quality Management for Battery Production: A Quality

Oct 30, 2017 · High costs and large quality fluctuations during the production of high-energy batteries are considered to be among the main impediments of electric cars to succeed on the

EU Battery Regulation

The new EU Battery Regulation 2023/1542 entered into force on 17 August 2023 and covers the whole lifecycle of batteries from production to reuse and recycling. While the Battery

Battery Energy Storage Systems Report

Jan 18, 2025 · This information was prepared as an account of work sponsored by an agency of the U.S. Government. Neither the U.S. Government nor any agency thereof, nor any of their

Energy Storage Quality Control

Mar 12, 2025 · Energy storage quality assurance and quality control (QA/QC) services ensure the reliability, safety, and long-term performance of battery energy storage systems (BESS)

Energy Management for Batteries in Electric Vehicles

May 9, 2023 · Integration of battery storage in PV power plants, commercial PV systems and hybrid PV mini-grids requires several steps of quality assurance: From detailed load profile

Quality Management for Battery Production: A Quality Gate

Jan 1, 2016 · In order to reduce costs and improve the quality of lithium-ion batteries, a comprehensive quality management concept is proposed in this paper. Goal is the definition of

Lithium-ion battery demand forecast for 2030

Jan 16, 2023 · Battery energy storage systems (BESS) will have a CAGR of 30 percent, and the GWh required to power these applications in 2030 will be

A Review on the Recent Advances in Battery

Nonetheless, in order to achieve green energy transition and mitigate climate risks resulting from the use of fossil-based fuels, robust energy storage

Battery technologies for grid-scale energy storage

Jun 20, 2025 · Energy-storage technologies are needed to support electrical grids as the penetration of renewables increases. This Review discusses the application and development

Quality Management for Battery Production: A Quality

Oct 4, 2023 · High costs and large quality fluctuations during the production of high-energy batteries are considered to be among the main impediments of electric cars to succeed on the

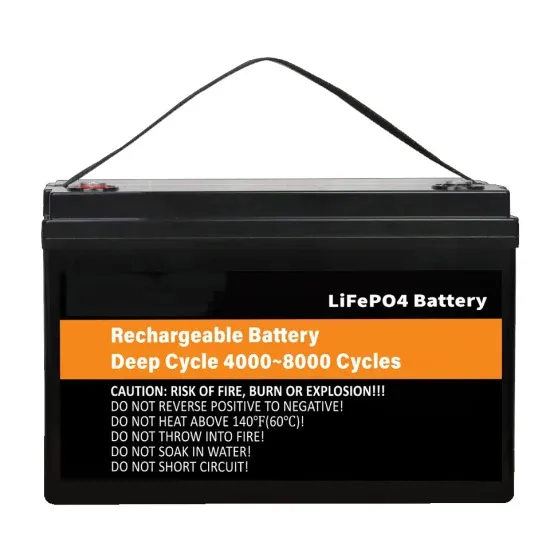

Commercial Batteries: Key Requirements for Performance

Jul 28, 2025 · Discover the essential requirements for commercial batteries, including performance, safety, environmental sustainability, and cost efficiency.

The Power Trio of Battery Quality: Assembly,

Sep 9, 2024 · As one of the most important outcomes of battery production, battery quality is the result of not only the assembly and testing processes of

Production & Testing Solutions Battery & EV Requirements

Apr 11, 2025 · Our Production and Environmental simulators test and assess the quality, durability and performance of batteries to make sure they meet your exacting specifications and

Life‐Cycle Assessment Considerations for

Jul 14, 2021 · Rechargeable batteries are necessary for the decarbonization of the energy systems, but life-cycle environmental impact assessments have

An Overview of

Oct 30, 2024 · The EU Batery Regulation contains articles about the restriction of substances, carbon footprint, recycled content, batery performance and durability, removability, safety of

Challenges and opportunities for high-quality

Jan 25, 2025 · The rise in battery production faces challenges from manufacturing complexity and sensitivity, causing safety and reliability issues. This

Advanced Lithium-Ion Energy Storage Battery

Jul 30, 2025 · Advanced Lithium-Ion Energy Storage Battery Manufacturing in the United States Due to increases in demand for electric vehicles (EVs), renewable energies, and a wide range

Key methods and implementation strategies for

Aug 12, 2025 · In order to improve the quality and reliability of batteries, CNS has summarized some key methods and implementation strategies in years of

A Look at Battery Production Processes: From

Jul 23, 2023 · The battery production process is crucial to the development of batteries that power electric vehicles, electronic devices, and renewable

Quality Control and Testing for Battery Energy

CEA''s proactive and robust Quality Control and Testing program proactively identifies and resolves issues at every stage of battery energy storage system

Challenges and opportunities for high-quality battery production

Jan 12, 2025 · Here we highlight both the challenges and opportunities to enable battery quality at scale. We first describe the interplay between various battery failure modes and their

Clean Room atmosphere requirements for

Apr 26, 2024 · The requirement for increased air dryness driven by the push for lower humidity levels in clean rooms has led to increased energy

Energy Storage Battery Production Requirements: What

The secret lies in energy storage battery production requirements – the unsung hero (or villain) behind every battery-powered gadget. This article breaks down the technical, environmental,

Battery Manufacturing Regulations and Standards Ensuring Quality...

Apr 11, 2024 · These measures streamline cross-border trade and promote a more efficient and transparent marketplace for battery products by ensuring that batteries meet the same

Battery energy storage systems | BESS

3 days ago · Battery energy storage (BESS) offer highly efficient and cost-effective energy storage solutions. BESS can be used to balance the electric

Challenges and opportunities for high-quality

Jan 25, 2025 · Here we highlight both the challenges and opportunities to enable battery quality at scale. We first describe the interplay between various battery

6 FAQs about [Quality requirements for energy storage battery production]

Are quality concerns a problem in battery manufacturing?

Given the thin profit margins (often 2–3%) 86 with which battery factories operate, quality concerns are often in tension with these manufacturing performance indicators. For instance, the decision of what to do with a batch of cells with marginal failures might be heavily debated between production and quality teams.

What is battery quality?

We now consider a second definition of battery quality: conformance. Conformance refers to how well a manufactured product conforms to its design 25. The battery industry often refers to nonconformance as “cell-to-cell variability” 22, 55, 56, 80.

How sustainable is battery production?

Finally, we mention that the sustainability of battery production is becoming an increasingly important manufacturing performance metric. For instance, an estimated 30–65 kWh are consumed in the factory for every kWh of cells produced 45, 87.

What is Quality Management in lithium ion battery production?

Quality management for complex process chains Due to the complexity of the production chain for lithium- ion battery production, classical tools of quality management in production, such as statistical process control (SPC), process capability indices and design of experiments (DoE) soon reach their limits of applicability .

Is battery quality a determinant of battery failure?

In summary, both senses of battery quality (defectiveness and conformance) are critical determinants of battery failure and thus the financial success of cell and EV production endeavors. We revisit battery quality in the “Managing battery quality in production” section.

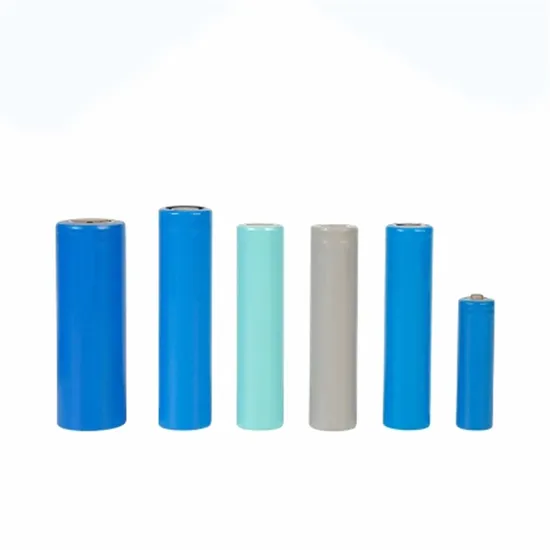

What is the best form factor for a battery?

The battery industry is currently pursuing three primary form factors: cylindrical, pouch, and prismatic. While many design criteria influence the optimum form factor for a given application, we propose that both quality and “quality inspectability” are also important.

Industry Information

- Huawei iron liquid flow battery composition

- Battery Energy Storage in Sao Paulo Brazil

- The value of energy storage wind power

- Which energy storage equipment is best in Monrovia

- Household photovoltaic energy storage

- Beijing Photovoltaic Inverter Manufacturer

- Dual Pump Solar Suction Pump

- Freetown Energy Storage Equipment Transformation Plan

- Liquid flow battery storage time

- 12v long cylindrical lithium battery

- Huawei Mobile Base Station Wind Power Supply

- Super high temperature resistant capacitor

- Is Sofia s energy storage battery good

- Lesotho Photovoltaic Energy Storage Price Company

- Off-grid household energy storage distribution box

- How much is the South Ossetian lithium battery pack

- Overall battery cabinet size standard

- Container energy storage battery assembly ESS power base station

- The purpose of the government building a communication base station EMS

- Solar lights one for two self-operated outdoor

- Cheap 1500w solar inverter for sale for sale

- Onsite energy solar panels energy storage battery self-operated

- Dakar Hybrid Energy and 5g Base Station Cooperation

Commercial & Industrial Solar Storage Market Growth

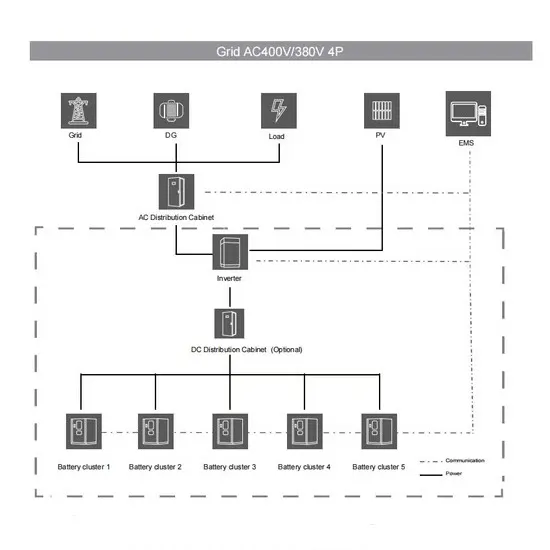

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.