Optimal design of high frequency H-bridge inverter for wireless power

Jun 10, 2016 · With the emergence of Wireless Power Transfer (WPT) systems in electric vehicle (EV) applications, variety of power electronics converters topologies are implemented. The

A comprehensive review on cascaded H-bridge multilevel inverter

Jan 1, 2021 · Recently, Multilevel Inverters has developed as a significant substitute in the field of high and medium power industrial applications. The multilevel inverters exhibits several

Wind and Solar Hybrid Power Full-Bridge Inverter Design

Nov 20, 2019 · This article is designed for wind and solar power generation system using single-phase full-bridge topology inverter microcontroller control. and link using modified sine wave

Full Bridge Inverter vs. Half Bridge Inverter

The Full Bridge Inverter is commonly used in high-power applications such as industrial motor drives, renewable energy systems, and grid-tied inverters. Its high efficiency and bidirectional

Easy 150 W Full-Bridge Inverter Circuit [Tested]

Nov 21, 2020 · Simple 150 Watt Full Bridge Inverter Figure 3 below shows the oscillator stage of our 150 watt full bridge inverter circuit diagram and it looks

Transformer Design Consideration for Full Bridge Phase Shift

Jan 28, 2022 · Full-Bridge Phase Shift (FBPS) The main features of the FBPS power converter are:

Challenges in Zero-Voltage-Switched-on Multi

Jan 1, 2025 · This paper investigates the challenges in designing and implementing silicon carbide (SiC) full-bridge inverters that operate at multi

Energy efficiency enhancement in full-bridge PV inverters

Jan 1, 2021 · Thus, transformerless single-phase inverters based on symmetrical AC filter inductors with the full-bridge configuration are preferring in terms of high efficiency and high

High Performance Control of Single-Phase Full Bridge Inverters

Oct 17, 2019 · Full bridge inverter are widely used as DC-AC power conversion interfaces in many areas such as PV application or interruptible power supply. The first and more important factor

Full Bridge Inverter : Construction, Working and

Inverters are classified into 2 types according to the type of load being used i.e, single-phase inverters, and three-phase inverters. Single-phase inverters are

Design Procedures and Prototyping of a Full-Bridge High Frequency Power

Dec 4, 2019 · Nowadays, power electronics inverters are everywhere, from customer electronics to industry applications. In the heart of these converters there are discrete semiconductor

Full-Bridge Inverter

A full bridge inverter is defined as a converter that enables the use of a continuous voltage source to supply a load with alternating voltage and current, functioning as a current- and voltage

DESIGN AND ANALYSIS OF FIVE LEVEL CASCADED H

Dec 8, 2021 · Fig. shows the power circuit for one phase leg of a nine-level inverter with four cells in each phase. The resulting phase voltage is synthesized by the addition of the voltages

Full-bridge converter – Electricity – Magnetism

Oct 26, 2023 · A full-bridge converter is a power electronics topology that efficiently converts DC voltage, offering high performance, isolation, and

Energy efficiency enhancement in full-bridge PV

Aalborg Universitet Energy Efficiency Enhancement in Full-Bridge PV Inverters with Advanced Modulations Tang, Zhongting; Sangwongwanich, Ariya; Yang, Yongheng; Blaabjerg, Frede

Transformerless H-Bridge Inverter Circuit

May 21, 2019 · In this post we discuss the method for making a simple transformerless H-Bridge Inverter Circuit Using IC IRS2453 (1)D and a few

Full Bridge Inverter – Circuit, Operation, Waveforms & Uses

Sep 10, 2024 · A full bridge inverter is a power electronics device that converts DC power to AC power. It achieves this by controlling the conduction and switching of four power switches

Design Procedures and Prototyping of a Full-Bridge High Frequency Power

Dec 4, 2019 · Design Procedures and Prototyping of a Full-Bridge High Frequency Power Inverter Published in: 2019 IEEE 15th Brazilian Power Electronics Conference and 5th IEEE Southern

Challenges in Zero-Voltage-Switched-on Multi-MHz Multi-kW SiC Full

Jan 3, 2025 · This paper investigates the challenges in designing and implementing silicon carbide (SiC) full-bridge inverters that operate at multi-MHz multi-kW, aiming at exciting high

Loss and efficiency comparisons of single-phase full-bridge inverters

Dec 27, 2023 · The purpose of this study is to analyze the performances of the single-phase full-bridge inverter according to different switch structures and to propose a cost-effective structure

A new IGBT control and drive circuit for high-power full-bridge

Jun 1, 2013 · In this paper, aiming at the characteristics of high-power full-bridge inverter, a new IGBT control and drive circuit is designed, in which UCC3895, a phase shift and dead-time

Single-phase full-bridge inverter

Feb 15, 2023 · In this installment of the course, we will examine the operation of the single-phase full-bridge inverter, an electronic device used to convert

Wind and Solar Hybrid Power Full-Bridge Inverter Design

Nov 20, 2019 · The inverter is a DC into AC circuit structure devices [4]. is composed of four full-bridge drive tube turns working on each band sine wave. more suitable for high-power

Phase-Shifted Full-Bridge Converter Fundamentals

Nov 20, 2024 · The phase-shifted full-bridge converter (PSFB) is common in high-performance power supplies with fast transient response, high power density and high converter eficiency.

Efficient single-phase full-bridge soft-switching inverter

Feb 22, 2021 · A MOSFET is often applied as the switch in medium and small power single-phase full-bridge inverters. In order to achieve efficient operation at a high switching frequency, a

Full Bridge Inverter (1-phase application)

Full bridge (H bridge) inverter (1-phase application) Description A simple and commonly used H-bridge type inverter. It is also called a two-level inverter

Choosing the right DC/DC converter for your energy

Sep 30, 2020 · Features Digitally-controlled bi-directional power stage operating as half-bridge battery charger and current fed full-bridge boost converter 2kW rated operation for discharge

Single Phase Inverter

Jul 23, 2025 · A full-bridge inverter is a type of H-bridge inverter employed for converting DC power into AC power . In contrast to single-phase half-bridge

Half-Bridge vs. Full-Bridge: What is the Difference?

May 12, 2022 · Full-bridge amplifiers are typically used at high power levels and can be found in audio amplifiers, RF power amplifiers, and motor controllers.

A high power density dual-buck full-bridge inverter based

Mar 19, 2015 · The Dual Buck Full-bridge Inverter (DBFBI) has great advantages in reliability and efficiency because of no shoot-through concerns, high utilization rate of DC input voltage, and

High-Voltage H-Bridge Inverter

In this project, we have designed and built a high-voltage H-bridge inverter, also known as a full-bridge inverter. This type of circuit is crucial in power

6 FAQs about [High power full bridge inverter]

What is a full bridge inverter?

Full bridge inverter is a topology of H-bridge inverter used for converting DC power into AC power. The components required for conversion are two times more than that used in single phase Half bridge inverters. The circuit of a full bridge inverter consists of 4 diodes and 4 controlled switches as shown below.

What is a bridge inverter?

It is a common topology in power electronics conversion. The full bridge inverter consists of four switches (S1, S2, S3, S4) that work in pairs to control the direction of current flow, thereby generating an AC voltage.

What is the difference between full bridge and half bridge inverter?

It is effective for medium to low power applications. Full bridge inverter: Higher cost due to more switches and complex control logic. Half bridge inverter: Lower cost as fewer switches are used and the circuit design is simpler. Choose appropriate switch devices based on the inverter's power and frequency requirements.

Can a full-bridge inverter be used for inductive load?

Operation of single-phase full-bridge inverter for inductive load. The load voltage in a full-bridge inverter is a square waveform like the pole voltage, so it contains a lot of harmonics. Its harmonic orders are the same as those of the pole voltage.

What is a single phase full-bridge inverter circuit?

Single-phase full-bridge inverter circuit The inverter circuit includes a full-bridge inverter and a filter circuit. wherein completion of full-bridge inverter converting DC to AC.

What is a high frequency inverter?

In many applications, it is important for an inverter to be lightweight and of a relatively small size. This can be achieved by using a High-Frequency Inverter that involves an isolated DC-DC stage (Voltage Fed Push-Pull/Full Bridge) and the DC-AC section, which provides the AC output.

Industry Information

- How much is the 5g base station battery quota

- Solar photovoltaic panels on rural roofs in Nouakchott

- Nordic outdoor power supply outdoor 220v

- China switchboard and switchgear

- Libya s energy storage photovoltaic

- Spanish photovoltaic glass sun room

- Communication base station solar installation manufacturer China

- Vilnius Solar Ecosystem

- China factory price 15kv switchgear for sale

- 6000w solar inverter in China in Cameroon

- Battery cabinet communication high voltage control system

- Singapore photovoltaic container substation production cycle

- Communication base station battery energy storage system construction announcement

- Huawei Angola Outdoor Power Supply BESS

- 3 Hundred-watt solar light

- Panama distribution room ups uninterruptible power supply brand

- What does photovoltaic combiner box mean

- Is an outdoor power bank a must-have for travel

- Libreville Outdoor Power Brand New EK

- Inverter single phase 120v to 380v

- Tallinn energy storage container customization

- Which energy storage lithium battery manufacturer is the best

- How to configure the water pump for solar system

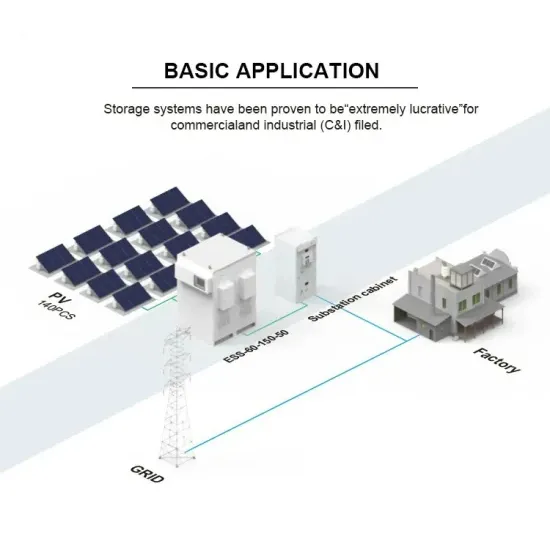

Commercial & Industrial Solar Storage Market Growth

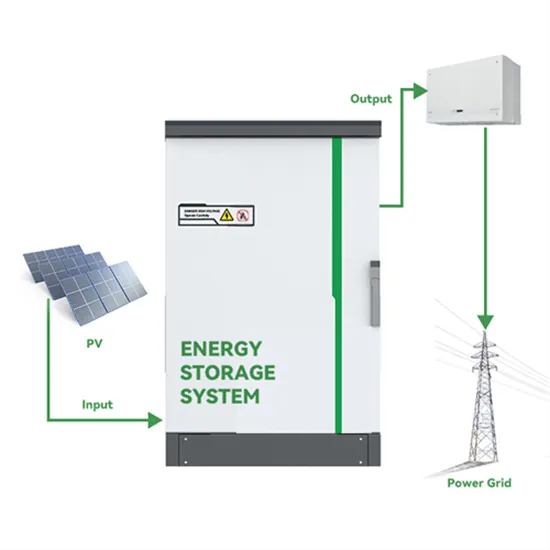

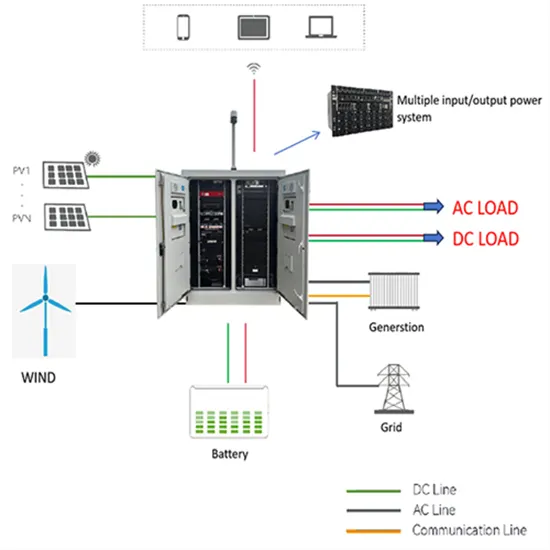

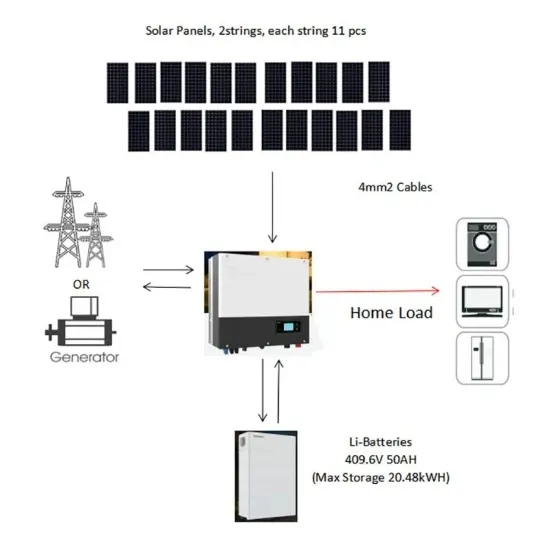

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.