Global PV module manufacturing to reach 1.8TW

Mar 24, 2025 · Solar supply chain in China increased by 29% in 2024. Image: Avaada Group. Australian thinktank Climate Energy Finance (CEF) has

Photovoltaics Report

Jun 6, 2025 · Note: In mass production, the cell-to-module ratio (CTM) improved in past years by reducing losses and using possible gains when integrating solar cells in modules.

India''s PV module production capacity hits 64.5

Apr 2, 2024 · India added 20.8 GW of solar module manufacturing capacity and 3.2 GW of new solar cell production lines in calendar year 2023, according to

Solar Cell Manufacturing: A Comprehensive Guide

Solar cell manufacturing is a critical process in the solar manufacturing sector, which has been growing rapidly in recent years. Solar cells are the building blocks of solar panels, which are

MANUFACTURING OF SOLAR PANELS: FROM CELL TO

Nov 22, 2022 · Here we have emphasized on complete panel manufacturing process viz. Manufacturing of PV Cell, different types of PV Cell, Solar Panels, Testing of Solar Panels,

Photovoltaic (PV) Module Technologies: 2020

Nov 2, 2021 · It accounted for greater than 90% of PV production in 2014 when total module shipments were about 40 GW (SPV Market Research 2019), and it accounted for around 94%

PV Module Manufacturing

Aug 13, 2025 · For real-world applications, photovoltaic modules are fabricated by electrically connecting typically 36 to 72 solar cells together in a so-called PV

Solar Cell Production: from silicon wafer to cell

Aug 17, 2023 · Producers of solar cells from silicon wafers, which basically refers to the limited quantity of solar PV module manufacturers with their own wafer

How Are Solar Cells Made? A Complete Guide

Sep 2, 2023 · Discover how are solar cells made in our in-depth guide. Dive into the detail of solar panel production, from raw materials to finished product.

SOLAR/PV EQUIPMENT – Semiphoton

Our automated Solar/PV modules production line includes a complete set of equipment, such as solar cells laser cutting, string soldering, welding, glass

Temperature Dependent Photovoltaic (PV) Efficiency and Its Effect on PV

Jan 1, 2013 · Solar cell performance decreases with increasing temperature, fundamentally owing to increased internal carrier recombination rates, caused by increased carrier concentrations.

Solar panel manufacturing process: from cell to

During lay-up, solar cells are stringed and placed between sheets of EVA. The next step in the solar panel manufacturing process is lamination. After having

Solar PV Manufacturing Basics Explained

2 days ago · Learn solar photovoltaic manufacturing basics, PV modules, racking systems, power electronics, and costs in a simple guide.

Solar PV

Oct 2, 2017 · Solar energy is the conversion of sunlight into usable energy forms. Solar photovoltaics (PV), solar thermal electricity and solar heating and

2.2 GW Cells + 3 GW Modules! Intensive Commissioning of PV Production

2 hours ago · On August 21, Insolation Green Energy, a subsidiary of India''s Insolation Energy, announced the official commissioning of its 3 GW PV module factory in Rajasthan. India''s PV

Annual solar module production worldwide

Jul 1, 2025 · In 2023, the production of solar modules worldwide reached approximately 612 gigawatts. In the last years, global solar module production

How to manufacture a photovoltaic module

5 days ago · By understanding the photovoltaic module production process and to learn which machines are involved in the production of a module, gives you

Module Manufacturing

Solar cells are the heart of a solar module. The manufacturing of Mono PERC (Passivated Emitter and Rear Contact) solar cells involves a series of highly precise and controlled steps to

PV Solar Cell Manufacturing Process

Explore the solar module manufacturing process in detail and discover how Smartech''s solutions enhance efficiency in PV cell production.

Solar panel manufacturing process: from cell to

During lay-up, solar cells are stringed and placed between sheets of EVA. The next step in the solar panel manufacturing process is lamination. Solar panel

Processes for the assembly and production of

The process of making solar panels Step 1: Half Cutting Using a laser cutter to divide the cells in two and switching to small area cells in series is a good

IEA: Global photovoltaic module production capacity will

Nov 1, 2024 · According to the International Energy Agency (IEA), global solar panel production capacity will exceed 1.5TW by 2035. Its latest report, Energy Technology Outlook 2024,

Solar Manufacturing Map

4 days ago · This map provides information about all of the solar photovoltaic (PV) manufacturing facilities in the United States and how they contribute to

Global solar manufacturing sector now at 50

May 7, 2024 · The International Energy Agency (IEA) says that global solar cell and module manufacturing capacity grew by around 550 GW in 2023. It

Solar Photovoltaic Panel Production Line Assembly

Solar Photovoltaic Panel Production Line is a high-tech manufacturing process that converts sunlight into electricity using photovoltaic cells, involving cutting,

The Solar PV Cell & Module Manufacturing Plant

Explore Saudi Vision 2030The Solar PV Cell & Module Manufacturing Plant is working to apply new solar energy technology and develop commercial-grade equipment suitable for severe

PV-Manufacturing – The free online resource

Silicon photovoltaic modules comprise ~90% of the photovoltaic modules manufactured and sold worldwide. This online textbook provides an

Production of PV Modules | SpringerLink

Feb 11, 2022 · The performance of a solar cell is measured using the same parameters for all PV technologies. Nowadays, a broad range of power

Global PV manufacturing capacity to reach 1 TW

Jun 8, 2023 · PV manufacturing capacity is projected to more than double by 2024, led by China, but oversupply is also anticipated, according to the

Flow Chart of the Solar Panel Manufacturing

May 18, 2024 · Discover the solar panel manufacturing process flow chart that begins with quartz and ends with photovoltaic prodigies. Learn why crystalline

Solar Panel Manufacturing Process Explained

Apr 29, 2023 · The Solar Panel Manufacturing Process The manufacturing process for solar PV panels typically involves several steps which include;

Powering the Future: Inside the Solar PV Cell

Oct 28, 2024 · Discover the remarkable journey of solar energy as we delve into the intricate process of photovoltaic (PV) cell manufacturing. From raw

PV cells and modules – State of the art, limits

The key components of photovoltaic (PV) systems are PV modules representing basic devices, which are able to operate durably in outdoor conditions. PV

How Are Solar Cells Made? A Complete Guide

Sep 2, 2023 · Solar cells, also known as photovoltaic cells, are made from silicon, a semi-conductive material. Silicon is sliced into thin disks, polished to remove

6 FAQs about [Photovoltaic cell module production]

What is photovoltaic (PV) cell manufacturing?

Discover the remarkable journey of solar energy as we delve into the intricate process of photovoltaic (PV) cell manufacturing. From raw materials to finished modules, this comprehensive overview illuminates the cutting-edge techniques and innovative technologies that transform sunlight into sustainable electricity.

What is a photovoltaic module?

For real-world applications, photovoltaic modules are fabricated by electrically connecting typically 36 to 72 solar cells together in a so-called PV module. A PV module (or panel) is an assembly of solar cells in a sealed, weather-proof packaging and is the fundamental building block of photovoltaic (PV) systems.

What is the PV cell manufacturing process?

The PV cell manufacturing process is a complex and precise endeavor that transforms raw materials into high-efficiency solar cells. From the initial production of silicon wafers to the final assembly of solar modules, each step requires strict quality control measures to ensure optimal performance and longevity.

How are PV solar cells made?

The manufacturing process of PV solar cells necessitates specialized equipment, each contributing significantly to the final product’s quality and efficiency: Silicon Ingot and Wafer Manufacturing Tools: These transform raw silicon into crystalline ingots and then slice them into thin wafers, forming the substrate of the solar cells.

How many solar cells are in a photovoltaic module?

An individual solar cell is fragile and can only generate limited output power. For real-world applications, photovoltaic modules are fabricated by electrically connecting typically 36 to 72 solar cells together in a so-called PV module.

What is PV module manufacturing?

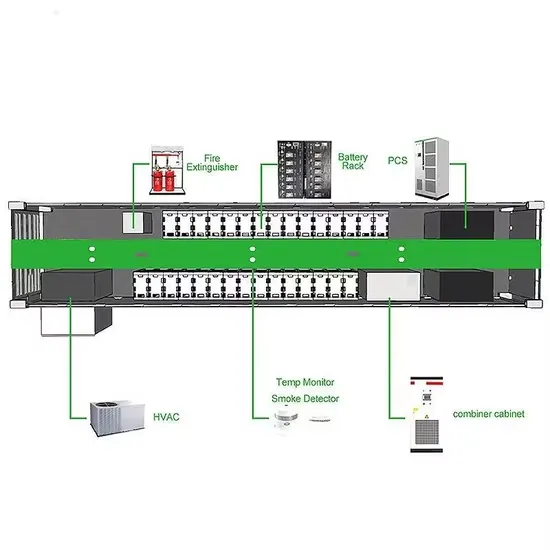

PV module manufacturing provides a diverse operation process since the system requires various components other than the PV panel. It includes cells, frames, wafers, glass back sheets, and power electronic parts.

Industry Information

- New Delhi inverter 12v to 220v home use

- Chad lithium energy storage system prices

- Huawei power station energy storage device usage

- China-Europe Photovoltaic Inverter

- Photovoltaic flat tile roof

- Breaker distribution for sale in Yemen

- Wholesale lv switchgear panel in Burundi

- Connect the inverter to charge the battery

- Industrial switchgear factory in Uk

- Huawei Australia Sydney New Energy Storage

- Luanda energy storage container manufacturer

- How much is the price of aluminum acid energy storage battery in Zimbabwe

- Saudi Arabia hybrid energy 5G base station construction

- Solar power storage solutions in Russia

- Cheap 15kw hybrid inverter in China producer

- Yuenengda Energy Storage Outdoor Power Supply

- Acs automatic energy storage system

- How many kilowatt-hours of energy can be stored in a base station

- Photovoltaic battery energy storage costs

- Transparent solar panels photovoltaic power generation

- BESS a Singapore energy storage system manufacturer

- Energy Storage Smart Grid

- Battery cabinet base station power generation project

Commercial & Industrial Solar Storage Market Growth

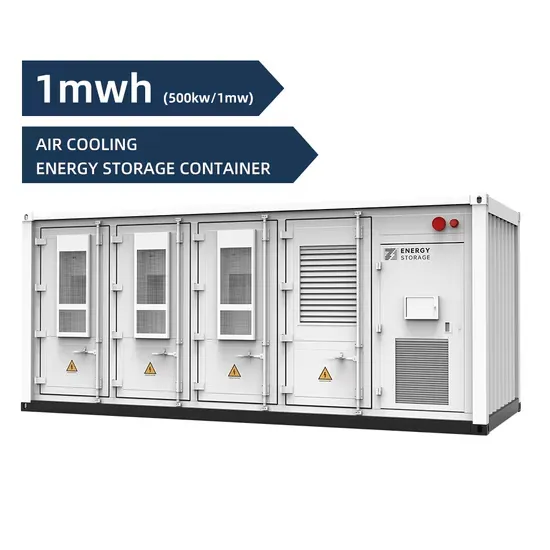

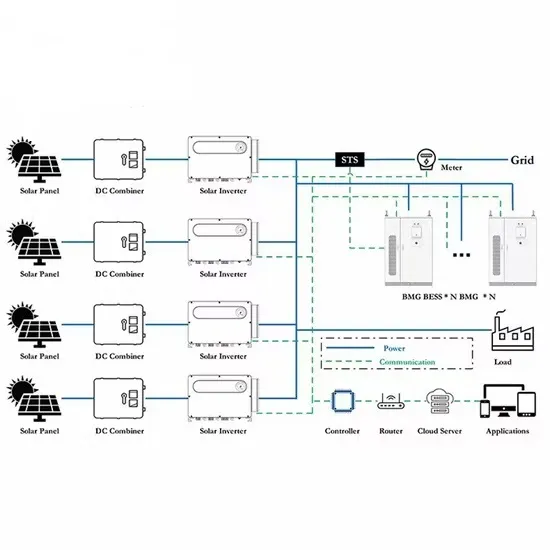

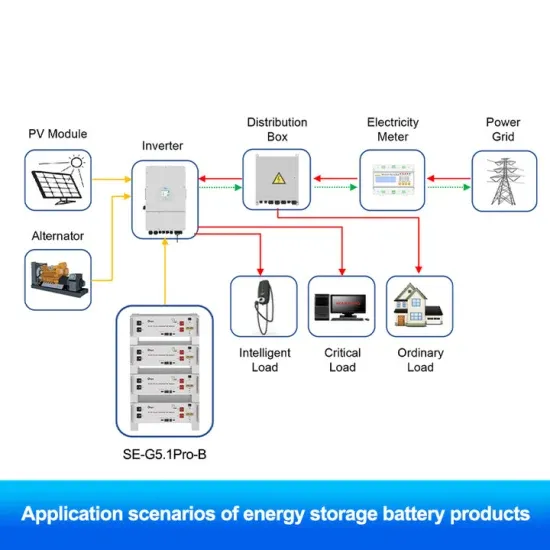

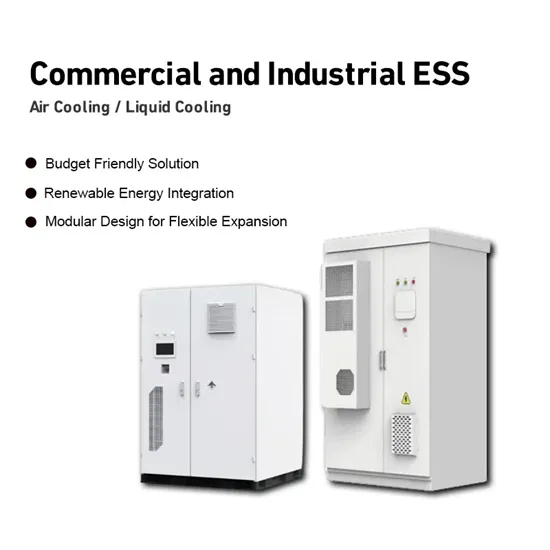

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.