Mastering Inverter Switching Frequencies: A

Apr 25, 2024 · The switching frequency of inverters in electric motor applications is critically controlled to optimize performance, efficiency, and minimize noise

Difference Between High and Low Frequency Inverter

Apr 30, 2025 · Why is the difference so big? Because it is determined by the orientation of their respective working principles: for high-frequency inverters, the inversion logic is inverted at

Voltage Fed Full Bridge DC-DC and DC-AC Converter for

Apr 1, 2023 · The DC-DC section consists of 120 V boot, 4A peak high frequency high-side and low-side driver UCC27211 for driving the high-side and low-side FET''s of the Full Bridge

High-frequency Power Inverter

Comparing HF Power Inverters and Traditional Inverters When comparing high-frequency power inverters with traditional low-frequency inverters, several differences become apparent. First,

Low-Frequency Oscillation Mechanism and Mitigation in

5 days ago · The grid-forming (GFM) control plays an important role in grid stability with the large-scale integration of renewable energy sources. In most GFM strategies, the inner voltage and

Low Vs High Frequency Inverters/UPS Comparison

In the world of renewable energy and uninterrupted power systems, inverters play a crucial role in converting direct current (DC) to alternating current (AC), which is essential for powering most

Understanding the Efficiency and Performance of Low Frequency

4 days ago · Low frequency power inverters play a crucial role in various electrical systems, providing a reliable and efficient means of converting low-frequency AC to high-frequency AC

The Role of Low-Frequency Solar Inverters in Off-Grid Solar

3 days ago · Conclusion Low-frequency solar inverters play a vital role in off-grid solar systems by providing increased efficiency, reduced EMI, enhanced reliability, and better utilization of

The Role of Frequency Inverters in Modern Industry

The integration of frequency inverters with IoT and smart systems is revolutionizing industrial operations. Modern frequency inverters now feature connectivity options that allow seamless

Understanding Frequency Inverters: A Comprehensive Guide

Feb 23, 2025 · A low-frequency inverter operates at a lower switching frequency, typically below 60 Hz. It is designed for applications requiring high power stability and minimal harmonic

Low Frequency VS High Frequency Inverter

May 2, 2023 · Weight: Low-frequency inverters are generally heavier than high-frequency inverters, mainly due to their larger and heavier transformers.

Understanding Low Frequency Power Inverters

6 days ago · – Higher efficiency: Low frequency inverters typically exhibit higher efficiency than high frequency inverters, which can result in significant energy savings over time. – Lower

What''s The Difference between A High Frequency And Low Frequency

Cost Considerations The cost of solar inverters plays a significant role in determining which type of inverter is best for your solar power system. High-frequency (HF) and low-frequency (LF)

What''s The Difference between A High Frequency And Low Frequency

Efficiency and performance are critical factors to consider when choosing between high-frequency (HF) and low-frequency (LF) solar inverters. These aspects directly impact how effectively your

Advantages of Low Frequency Inverters vs. High Frequency Inverters

6 days ago · In general, low frequency inverters are a better choice for applications where cost, efficiency, noise, and lifespan are important. High frequency inverters are a better choice for

Understanding the Differences

3 days ago · Conclusion Whether opting for a low-frequency or high-frequency solar inverter depends on the individual''s specific requirements and priorities. Low-frequency inverters offer

Understanding the Difference Between Low

Mar 7, 2023 · What are low frequency inverters? These transformer-based inverters are mainly utilized in solar power systems and backup power

Inversion Methods Explained: High Frequency vs Low Frequency

4 days ago · Understand the difference between high frequency and low frequency inverters with this quick article.

High-Frequency vs. Low-Frequency Inverters

Two main types of inverters are high-frequency and low-frequency inverters. Each type has its advantages and disadvantages, making them more suitable for specific applications. Let''s

High Frequency Inverter vs Low Frequency

Aug 18, 2025 · Discover the disparities between high frequency inverter vs low frequency inverter in this concise article, aiding your decision-making process.

Low Frequency vs High Frequency Inverters: Key

Aug 15, 2025 · Explore the key differences in low frequency vs high frequency inverters including their applications, advantages, and which is best for your

What is low frequency inverter? Why choose it?

Dec 30, 2022 · Two Areas: Peak Power Capacity & Reliability Low-frequency inverters have advantages over high-frequency inverters in two areas: peak

The Role of Low-Frequency Power Inverters in Backup Power

6 days ago · Unveiling the Long-Lasting Legacy of Low Frequency Unlike their high-frequency counterparts, low-frequency inverters operate at a slower frequency, typically 50 or 60 hertz.

High Vs Low Frequency Inverters/UPS

Jul 1, 2023 · Let us compare High Vs Low-Frequency Inverters/UPS Comparison. Two kinds of commonly used Inverters/UPS; High Frequency and Low

The Science Behind Low-Frequency Solar Inverter

2 days ago · Introduction Low-frequency solar inverters have emerged as a game-changing technology in the renewable energy landscape. These inverters offer numerous advantages

Guide to Frequency Inverters: Optimizing Motor

I. Introduction to Frequency Inverters (VFDs) Frequency inverters, also known as variable frequency drives (VFDs), are essential components in modern motor control systems. These

Understanding the Difference Between

Jan 21, 2025 · In the world of energy conversion and power electronics, inverters play a crucial role in transforming DC (direct current) into AC (alternating

Power Frequency Inverter vs High-Frequency Inverter

Nov 14, 2024 · Low-frequency power inverters have much better peak power capability to manage large loads with power spikes than high-frequency inverters. In fact, low-frequency inverters

Low frequency inverter vs high frequency

Mar 12, 2025 · Understanding the Difference between Low-Frequency and High-Frequency Inverters. Low-Frequency Inverter. A low-frequency inverter uses a

A Brief Overview of Low-Frequency Power Inverters

Low-frequency power inverters play an important role in solar power generation systems and UPS uninterruptible power supplies. They not only convert DC

Low-Frequency vs. High-Frequency Inverters: Technical

Jul 17, 2025 · This analysis evaluates the performance characteristics of low-frequency (LF) and high-frequency (HF) inverters based on current industry data and technical literature. Key

Which is Better Low Frequency or High

3 days ago · Introduction Inverters convert DC power into AC power to operate AC equipment and devices. They utilize power electronic switching at different

6 FAQs about [The role of low-frequency and high-frequency inverters]

What is the difference between low frequency and high frequency inverters?

Low frequency inverters generally have a longer lifespan than high frequency inverters due to their more durable components. In conclusion, low frequency and high frequency inverters have their unique features and benefits. Low frequency inverters are ideal for applications that require high power output and can handle heavy-duty appliances.

What is a low frequency inverter?

Efficiency: Low-frequency inverters are known for their robustness and ability to handle high surge currents, making them suitable for powering heavy-duty appliances or equipment with high starting currents, such as motors and compressors.

What are the advantages of a high frequency inverter?

High frequency inverters typically have an output of 20kHz or higher. Smaller size and weight compared to low-frequency inverters. Higher efficiency due to reduced power losses. Greater accuracy in output waveform due to the high frequency. Lower electromagnetic interference (EMI) due to higher switching frequency.

What is a high frequency inverter?

Applications: These inverters are more suitable for off-grid systems where heavy loads and extreme conditions are expected, such as in industrial applications or in remote locations with harsh environments. Weight: High-frequency inverters are lighter than low-frequency inverters, using smaller, lighter transformers.

Does victron use a high frequency inverter?

Victron combines both inverters, which they call Hybrid HF or Combined high frequency and line frequency technologies. What frequency inverter does growatt use? Growatt uses a high-frequency inverter. Which one is best? Low or high frequency? The best inverter is the low-frequency inverter.

What are the disadvantages of a high frequency inverter?

Limited output frequency range. Poor quality of AC power output, which may affect the performance of sensitive electronics. Large size and weight due to the use of transformers. Limited range of speed control. Noisy operation due to the use of transformers. What are high frequency inverters?

Industry Information

- 24V solar energy storage integrated machine

- Energy storage cabinet installation documentation

- Flow battery prices in Slovenia

- El Salvador Central Inverter Manufacturer

- Lithium battery to inverter fast charging

- 12v3000w inverter full load current

- 12v20w photovoltaic panel price

- Installation of outdoor solar energy storage battery cells for communication base stations

- Andor Energy Storage Cabinet Battery Company

- Battery cabinet base station cabinet type

- Can the Windhoek outdoor power supply be used by customs

- Singapore Power Plant Flywheel Energy Storage Project

- Factory price safety breaker in Cebu

- Communication operator base station data query

- Tirana Bifacial Solar Panel Manufacturer

- 220V to 60V inverter

- Solar Micro Water Pump 3-9v

- Photovoltaic lithium battery energy storage for new energy vehicles

- Cairo Energy Storage Container Park Design

- Construction of Palau photovoltaic energy storage project

- Is the portable emergency power supply easy to use

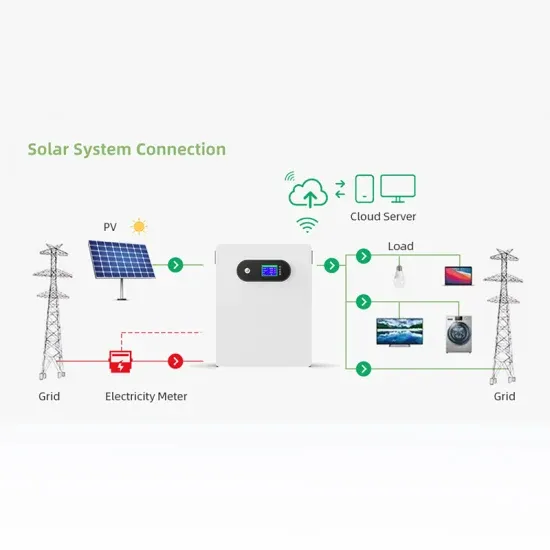

- Household energy storage battery solar power generation

- Photovoltaic inverter used as UPS

Commercial & Industrial Solar Storage Market Growth

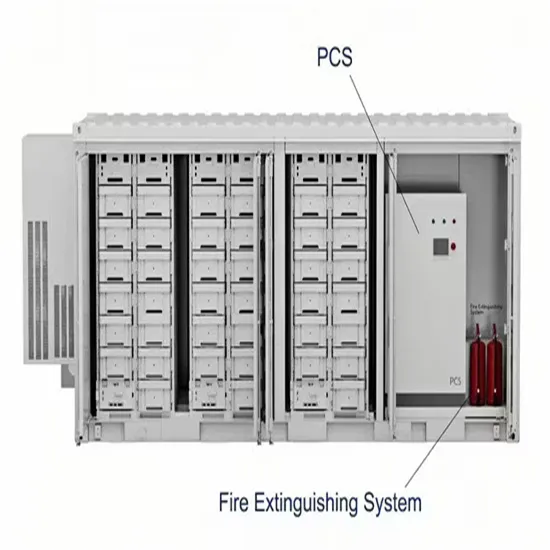

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.