How much power does an inverter use on

Apr 9, 2023 · Does an inverter consume power with no load is connected? Here, we will expain how much power does an inverter consume without load and

High Frequency Inverter Technical Specifications Explained

Aug 7, 2025 · When it comes to inverter technology, high frequency is the new normal. These are light weight inverters that use smaller transformers as compared to low frequency inverters

A Guide to Inverter Drives | RS

Sep 30, 2024 · Inverter drives are essential for applications requiring variable speed motors, such as industrial automation and HVAC systems. They

What is the Frequency Inverter Working Principle?

Apr 11, 2022 · After the fan and pump loads adopt frequency inverter, the power saving rate is 20% to 60%, which is because the actual power consumption of the fan and pump loads is

Application of frequency converter in ventilator control

Jun 11, 2025 · 1.Energy saving effect and operation stability of frequency converter Controlling ventilators with frequency converters can significantly reduce energy consumption. In

What is a Frequency Inverter?

Sep 2, 2024 · A frequency inverter is designed to manage the operation of electric motors by adjusting the frequency of the input power. By controlling the speed

The method of reducing the CMOS inverter switching energy

Aug 11, 2023 · In CMOS inverters, the main part of the power supply is spent on charging the parasitic capacitance of the transistor gates and the load capacitance. Associated with this

Application Analysis of High

Aug 18, 2025 · High-voltage inverters employ a cascaded multilevel topology, producing an output waveform that closely approximates a sine wave. They can directly output high-voltage AC

How much power does an Inverter use just sitting there idling?

Oct 30, 2020 · Generally a 3 kW sinewave high freq inverter is 30 to 50 watts of full idle power. A high frequency inverter has two primary stages. First stage is high frequency DC to DC

High frequency vs low frequency pure sine wave

Aug 16, 2016 · By definition, Low frequency power inverters got the name of "low frequency" because they use high speed power transistors to invert the DC

Idle Power Consumption of an Inverter or

Aug 14, 2024 · Suppose you have a 5.5 kW inverter with an idle power consumption of 50 watts. Now, if you connect a 1 kW load to it, would the total

A novel inverter control strategy for maximum

Feb 6, 2025 · The conventional inverter is undergoing a transformation into a smart inverter, driven by the expanding penetration of Photovoltaic (PV) power

Frequency inverters

A frequency inverter is a technical device that generates a different AC voltage from the incoming AC voltage. Frequency converters are used, for example, to

Application Analysis of High

Aug 18, 2025 · Thermal power remains vital in the global energy mix, yet traditional systems face challenges of high energy consumption and emissions, requiring innovation for greener

Nine-level high-frequency inverter | IET Power Electronics

Oct 31, 2018 · A multi-level high-frequency inverter topology based on a forward converter is proposed in this study, which implements the electrical isolation of input and output. With the

Using VFD''s to reduce energy consumption

Feb 28, 2025 · Using VFD''s to reduce energy consumption An VFD reduces energy consumption by efficiently regulating the speed of a motor or controlling the output of electrical devices. In

A Comprehensive Analysis: Inverter vs.

Mar 6, 2025 · But when comparing inverter compressors 1 with traditional fixed-speed compressors 2, which one is the better choice? Inverter compressors

The difference between high frequency inverter

May 15, 2024 · High frequency inverters are more efficient and portable, making them suitable for applications where energy consumption and size are critical

Inverter Power Calculator, Formula,Inverter Calculation

4 days ago · Enter the values of rated inverter power, RP(W) in watts and efficiency, E to determine the value of Inverter power, Pi(W).

Surge vs. Efficiency: Choosing Between Low and High-Frequency Inverters

Jul 25, 2025 · The high-frequency inverter is a sophisticated, efficient, and compact design perfectly suited for modern electronics, renewable energy, and any application where size and

12 Things to Know About the Type of Frequency of Solar Inverters

Aug 8, 2023 · 1 Power Factor: The power factor is 1, indicating that high-frequency inverters have no reactive power during energy conversion, making them highly efficient. 2 Self-Consumption:

Review of very high frequency power converters

Jul 1, 2020 · The matching networks are added between the inverter stages and rectifier stages to adjust the equivalent impedance of the rectifier stage. Fig. 4

How to Test a Frequency Inverter?

Dec 17, 2023 · Frequency inverter is an important power regulation device in the field of industrial automation, which is used to change the frequency of the

A High Performance High Frequency Inverter Architecture

Oct 14, 2021 · In this work, a high frequency inverter system that can work in a wide range of inductive or capacitive load is proposed, which includes Class D inverter, novel

Idle ''no load'' Consumption: Specs vs Your Personal Observation

Dec 10, 2019 · I have seen those AIMS inverters, huge idle draw, I measured it at 200 watts idling...The low frequency inverters have a larger idle draw than most high frequency inverters.

Power Frequency Inverter vs. High Frequency

May 15, 2024 · High frequency inverter: High frequency inverters use high-frequency switching technology to chop DC power at high frequency through

Understanding the Power Consumption of Inverter

Several factors can impact the power consumption of inverter refrigerators, including the size and capacity of the appliance, its energy efficiency rating, and external environmental conditions.

What is the Frequency Inverter Working Principle?

Apr 11, 2022 · The energy-saving of the frequency inverter is mainly manifested in the application of fans and pumps. After the fan and pump loads adopt frequency inverter, the power saving

Frequency inverters | Explanation, function

Frequency inverters are electronic devices that create an AC voltage with variable frequency from an AC voltage with fixed frequency (e.g. 50 Hz). They are

Surge vs. Efficiency: Choosing Between Low and High-Frequency Inverters

Jul 25, 2025 · Line-Frequency vs. High-Frequency Inverters: A Technical Deep Dive for Engineers In the world of power electronics, the inverter is a cornerstone technology, responsible for the

How Is the Frequency Inverter Used in the Central Air

3 days ago · Introduction Central air conditioning systems are a cornerstone of modern building management, providing comfort and climate control across various commercial and residential

Understanding Frequency Inverters: A Comprehensive Guide

Feb 23, 2025 · A frequency inverter is an electronic device that converts AC power from one frequency to another, allowing motor-driven systems to operate at variable speeds. This

The Need for High-Frequency High-Accuracy Power

Nov 24, 2015 · The Need for High-Frequency High-Accuracy Power Measurement As more and more innovation focuses on energy efficiency and the use of renewable energy resources,

6 FAQs about [Actual power consumption of high frequency inverter]

How much power does a high frequency inverter use?

High frequency MOSFET drive switching is usually the dominate idle consumption but a poorly designed output PWM low pass filter can add to idle losses by having a high reactive power factor load. Generally a 3 kW sinewave high freq inverter is 30 to 50 watts of full idle power. A high frequency inverter has two primary stages.

Are high frequency inverters more efficient?

High frequency inverters are generally more efficient than low frequency inverters, as they are able to convert DC power to AC power with less energy loss. This efficiency is particularly beneficial in applications where power consumption is a critical factor.

Are power frequency inverters good?

In contrast, power frequency inverters can maintain high efficiency and stability under heavy load or overload. Output waveform quality: The output waveform quality of power frequency inverters is usually better than that of high frequency inverters.

What is the output frequency of a high-frequency inverter?

The output frequency of the high-frequency inverter is much higher than the power frequency, usually between a few kilohertz and tens of kilohertz.

What is a frequency inverter?

The frequency inverter is to achieve speed adjustment by changing the frequency of the motor power supply, which is an ideal way of achieving high efficiency and high-performance speed regulation.

How does a high frequency inverter work?

A high frequency inverter has two primary stages. First stage is high frequency DC to DC converter that pumps battery voltage up to about 180-200vdc. Second stage is output MOSFET H-bridge that takes the high voltage DC and PWM chops it for sinewave synthesis, follow by low pass L-C filter.

Industry Information

- Andorra Small Solar Air Conditioner Price

- Portable power to connect the home

- Sana s new supercapacitor car price

- Energy storage power station demonstration

- What are the container power generation equipment in Ecuador

- Disadvantages of photovoltaic cascade energy storage power stations

- Türkiye 210 degree liquid cooling energy storage cabinet solution

- 10 monitors how many watts of solar energy

- Level 5 communication base station inverter

- 1000 wh power station factory in Costa-Rica

- Belgian zinc-iron liquid flow energy storage battery

- Smart Energy Storage Battery Cabinet Manufacturer Ranking

- Timor-Leste hybrid energy 5g700m base station hybrid power supply

- How big of an inverter should a 1000ah lithium battery be matched with

- Construction work of wind and solar complementary communication base station at night

- Ankara Energy Storage Container Production

- Lithium battery station cabinet double shoulder

- Banji Smart Photovoltaic Water Pump Inverter

- HA16 Battery Cabinet

- Niue Photovoltaic Power Inverter

- How much does photovoltaic glass weigh

- North Macedonia inverter wholesaler

- South Sudan Power Grid Energy Storage Enterprise

Commercial & Industrial Solar Storage Market Growth

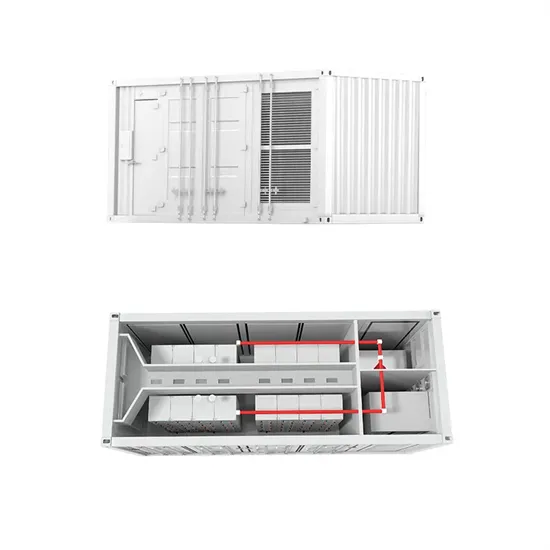

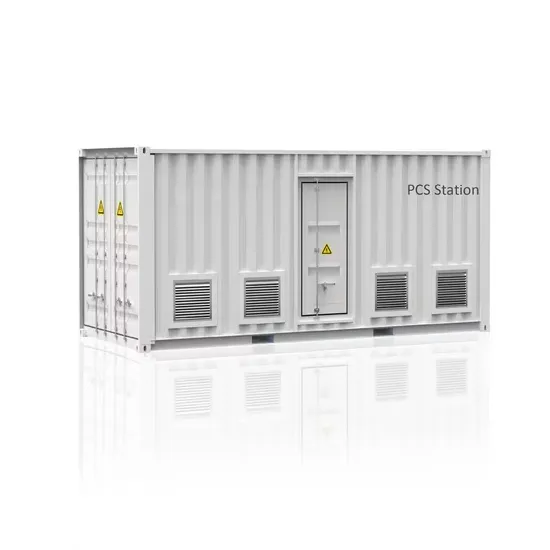

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.