72 Cell Solar Panels

Feb 12, 2021 · With larger commercial and utility scale projects, larger panel sizes are able to be used. So, 72 cell panels give them a way to regularly make solar panels over 300W. Higher

Silicon solar cells: toward the efficiency limits

Jun 5, 2023 · In this paper, we review the main concepts and theoretical approaches that allow calculating the e ciency ffi limits of c-Si solar cells as a function of silicon thickness. For a given

What you need to know about amorphous

Apr 25, 2023 · The world of solar panel tech is ever-changing, with exciting new options to explore. Join us as we delve into the workings of amorphous silicon

Solar panel technical specifications Malta

Technical Drawing** Dimensions in mm To know more about our range of solar solutions call Toll Free 1800 419 8777 or visit * Irradiance of 1000W/m2, spectrum AM of 1.5 and cell

How to tell the wattage of a solar cell | NenPower

Apr 11, 2024 · Identifying the wattage of a solar cell necessitates a multifaceted approach centered on measurement, understanding, and adaptability.

How many watts per kilogram of solar cell | NenPower

Aug 24, 2024 · The primary technologies employed in solar cells include silicon-based cells, thin-film cells, and emerging technologies such as perovskite and organic solar cells. Each type

Making cheaper, better solar panels, right here

Research has started at the lab to find ways of improving efficiency in solar energy systems and making them cheaper. The benefits are not just for Malta

Solar Silicon Wafer Size M0 M2 G1 M6 M10 G12

Jan 8, 2024 · What do "M" and "G" stand for in solar wafer size? It begins with the letter "G", which means that the solar silicon wafer is full square Beginning

How many watts does a solar silicon wafer

May 2, 2024 · Solar silicon wafers typically range from 250 to 400 watts; 2. Factors such as size, type, and manufacturer can influence the wattage; 3.

How Do Solar Cells Work? Photovoltaic Cells

Jul 25, 2024 · You''ve probably seen solar panels on rooftops all around your neighborhood, but do you know how they work to generate electricity? In this

Microsoft PowerPoint

Feb 24, 2011 · Typical mono‐ and polycrystalline silicon solar cells (upper), and simplified cross‐section of a commercial monocrystalline silicon solar cell (lower) (© 2010 Sharp).

Solar Silicon Wafer Size M0 M2 G1 M6 M10 G12

Jan 8, 2024 · The silicon wafer size has undergone three major changes: the first stage from 1981 to 2012, the silicon wafer size is mainly 100mm, 125mm; The

How many watts is a solar cell | NenPower

Feb 2, 2024 · 1. A solar cell typically produces between 250 to 400 watts of power, depending on its size and efficiency. 2. Factors influencing wattage

Polycrystalline Solar Panel Specifications

Nov 17, 2023 · The surface of these solar cells resembles a mosaic which comes under polycrystalline solar panel specifications. These solar panels are square

BR-041001 Crystalline Silicon_Catalog Layout

Laser-Based Manufacturing Processes on c-Si Solar Cells The use of lasers in making photovoltaic devices can both improve cell efficiencies and reduce overall manufacturing costs

Silicon solar cells: materials, technologies, architectures

Jan 1, 2020 · A solar cell in its most fundamental form consists of a semiconductor light absorber with a specific energy band gap plus electron- and hole-selective contacts for charge carrier

Solar Panel Sizes and Wattage: Everything You

Mar 25, 2024 · Solar panel sizes and wattage: Get information about the standard panel dimensions and wattage range to optimize your solar energy system.

Development of Higher Efficiency Mono Crystalline

Mar 7, 2022 · Abstract: At present mono crystalline silicon solar cells are more established and mostly used to generate electricity rather than using thin films crystalline silicon solar cells,

High Efficiency Solar Panels | Maxeon

4 days ago · High Efficiency Solar Panels - Maxeon by SunPower. Our High Efficiency Solar Panels are designed to be different and proven to be better

Status and perspectives of crystalline silicon photovoltaics in

Mar 7, 2022 · Crystalline silicon solar cells are today''s main photovoltaic technology, enabling the production of electricity with minimal carbon emissions and at an unprecedented low cost. This

Research on hot spot risk of high wattage solar modules

Dec 1, 2021 · This research proves the effectiveness of using finite element analysis (FEA) to study the hotspot risk, and points out a new direction for how to control the hotspot risk of high

60 Cell vs. 72 Cell Solar Panels: Which is Right

Aug 30, 2018 · There are many different types of solar panels available on the market, with options ranging in efficiency, wattage, manufacturer, appearance,

What Are The Most Popular Sizes Of

May 30, 2024 · What Are The Most Popular Sizes Of Monocrystalline Silicon Solar Cells On The Market Today? In recent years, single crystal silicon solar

Silicon Improvement for Higher Cell Efficiency Project

Apr 25, 2023 · Single-crystal silicon accounts for most of the solar capacity installed worldwide, with the efficiency of the top-performing solar panels currently ranging between 21%-22%.

Towards the efficiency limits of multicrystalline silicon solar cells

Oct 1, 2018 · We demonstrate a certified world record efficiency of 22.3% for an mc-Si solar cell. We present a detailed loss analysis of n-type mc-Si TOPCon solar cells. Jsc losses are

How many watts per kilogram of solar cell | NenPower

Aug 24, 2024 · How many watts per kilogram of solar cell: The energy output of solar cells, quantified in watts per kilogram, varies significantly depending on multiple elements such as

Monocrystalline solar panels: the expert guide

Jul 25, 2025 · What are monocrystalline solar panels? Monocrystalline solar panels are made with wafers cut from a single silicon crystal ingot, which

Solar Cell Production Process: From Silicon to

Apr 29, 2023 · Discover the solar cell production process, from silicon wafers to energy generation. Learn how solar cells are made for efficient, sustainable

How Much Power Does a Single Solar Cell

Jun 16, 2024 · A single solar cell can produce up to 6 watts of power, while a typical residential solar panel with multiple cells can generate 250-400 watts of

How Many Solar Cells Are in a Typical Panel?

Jun 2, 2024 · Explore the typical count of silicon cells in solar panels, their wattage, size, efficiency, and types: monocrystalline vs. polycrystalline.

Harnessing Sunshine: A Comprehensive Guide to

Aug 28, 2023 · As Malta strives to embrace renewable energy sources, harnessing the abundant sunshine through solar panels emerges as a

Characteristics of Crystalline Silicon PV Modules

Jan 21, 2022 · Monocrystalline silicon solar cells are more efficient than polycrystalline silicon solar cells in terms of power output. In order to increase

6 FAQs about [Wattage of Malta silicon solar cells]

Can n-type multicrystalline silicon improve solar cell efficiency?

In the past years, research on n-type multicrystalline silicon revealed its large solar cell efficiency potential.

How efficient is a mc-Si Topcon solar cell?

We demonstrate a certified world record efficiency of 22.3% for an mc-Si solar cell. We present a detailed loss analysis of n-type mc-Si TOPCon solar cells. Jsc losses are correlated with recombination active structural crystal defects. FF losses are assessed by simulations with Quokka3 considering GB recombination.

How efficient are mc-Si solar cells?

The optimized emitter diffusion temperature led to a slight increase in Jsc, which was compensated by a slight reduction in the fill factor. It is noteworthy that nearly all mc-Si solar cells of the second batch feature efficiencies above 21%, 11 of which even above 22%.

What are the electrical losses of a record mc-Si solar cell?

FELA of the record mc-Si solar cell. The main electrical losses are grain boundary recombination and emitter recombination. 6. Summary and outlook In this work we presented a detailed loss analysis of our record mc-Si TOPCon solar cells, which explains the observed differences compared with FZ reference cells for the IV parameters.

How much fa/cm2 does a solar cell use?

For comparison, the impact of a J01,e of 30 fA/cm 2 (typical value for the reference solar cells) and 70 fA/cm 2 (used in the simulations for the record mc-Si cell in Section 5.3) on the inner grain bulk lifetime is also shown in Fig. 5.

What is the efficiency gap between multicrystalline and Fz reference solar cells?

We observe an efficiency gap between the multicrystalline and the FZ reference solar cells of ~1%abs. Compared to the FZ reference cells, the mc-Si cells also feature a significantly larger scattering in V oc and J sc as well as a fill factor loss of ~1.5% abs.

Industry Information

- 5kwh hybrid inverter for sale in Cambodia

- Eritrea RV Solar System Manufacturer

- 200W photovoltaic panel price

- Portable power solar station in Bolivia

- Cheap sf6 circuit breaker in hindi distributor

- Is wind and solar energy storage considered wind and solar power generation

- Where can I find a battery cabinet in Slovakia

- Huawei West Asia Energy Storage Project

- Svc outdoor power supply

- Juba Base Station Energy Storage System Price

- Water pump powered by solar energy

- TGN24A Inverter

- Communication base station battery factory 6 25MWh

- Huawei s photovoltaic modules exported to Liberia

- Ankara commercial energy storage equipment manufacturer

- Georgetown Energy Storage Container Manufacturer Contact System

- Energy storage battery customization wholesale

- Feasibility of solar photovoltaic energy storage cabinet station

- Kinshasa Portable Energy Storage Power Plant

- Tiraspol Energy Storage Equipment Quote

- Abuja Communication Base Station Lithium Ion Battery Price

- Jerusalem 75kw high quality inverter

- Thailand battery energy storage module price

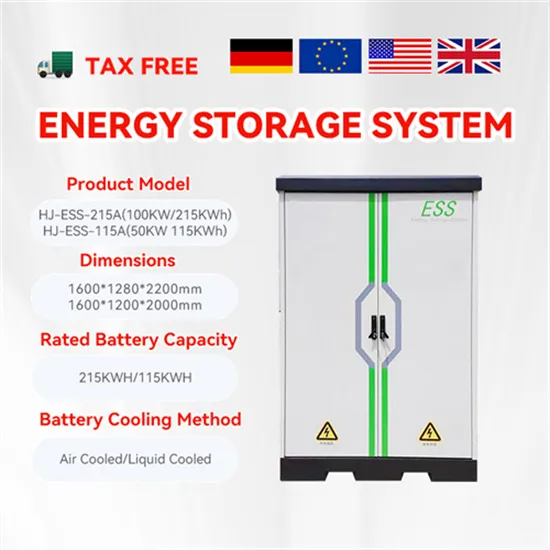

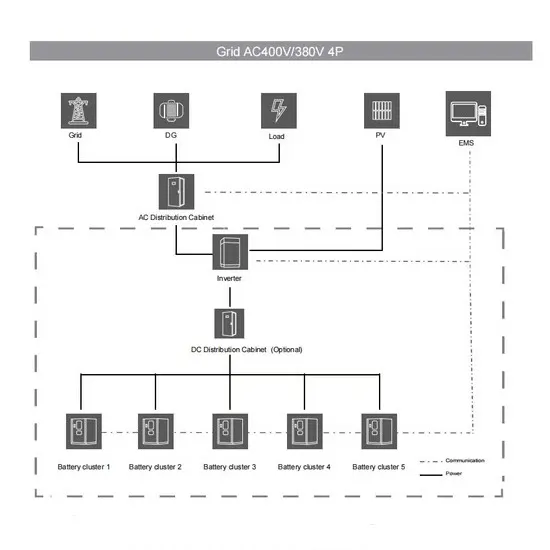

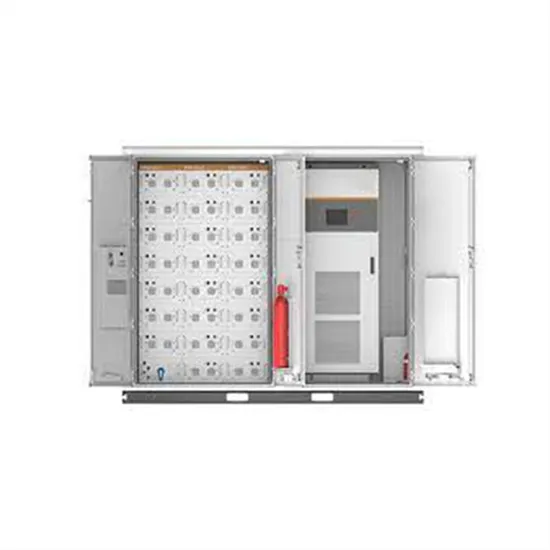

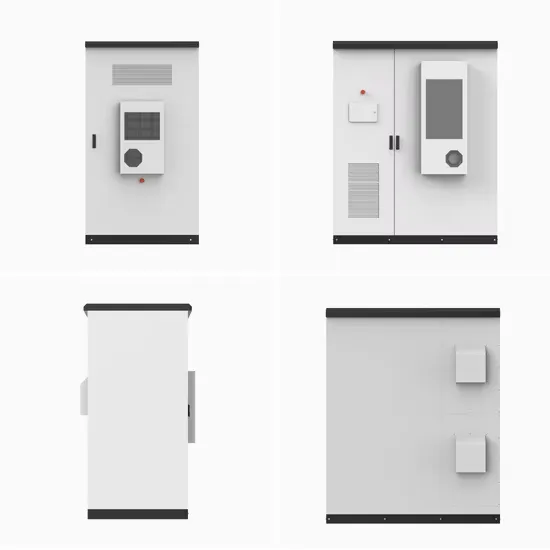

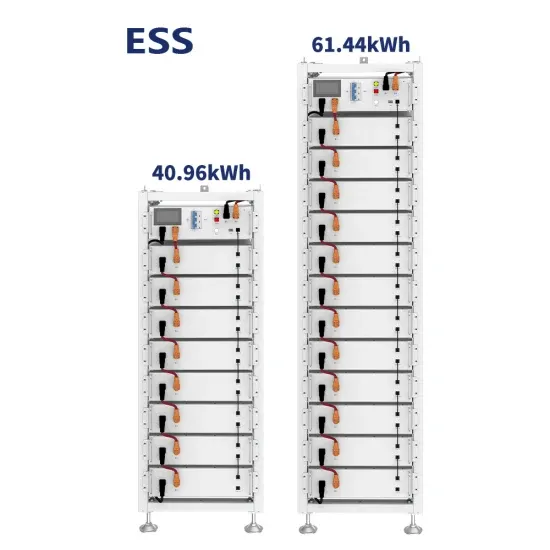

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

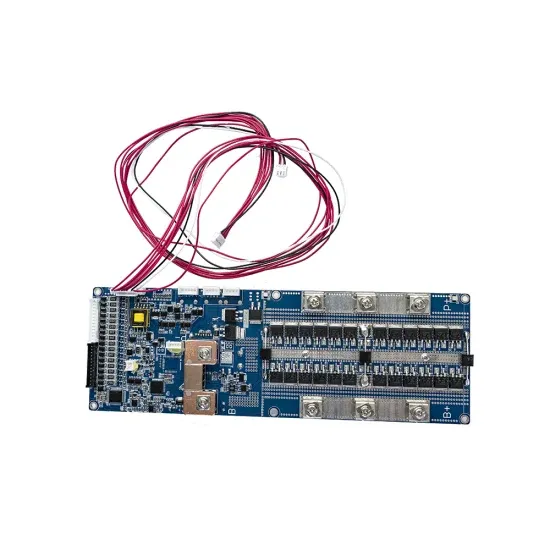

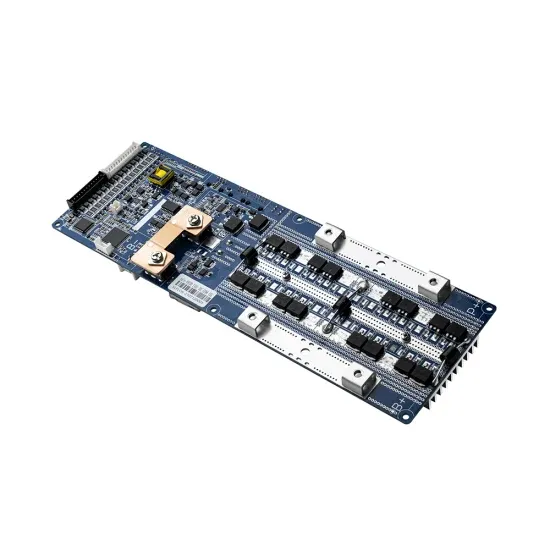

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.