Induction machine-based flywheel energy storage

Sep 11, 2023 · Mansour M, Rachdi S. Mohamed Néjib Mansouri, Mohamed Faouzi Mimouni, direct torque control strategy of an induc-tion ‐machine‐based flywheel energy storage system

Modeling Methodology of Flywheel Energy Storage

Sep 29, 2022 · The motor generates higher torque, which drives the flywheel at a higher rota-tional speed. Hence, the flywheel stores the energy kinetically, which is proportional to the

The Status and Future of Flywheel Energy Storage

Jun 19, 2019 · The core element of a flywheel consists of a rotating mass, typically axisymmetric, which stores rotary kinetic energy E according to (Equation 1) E = 1 2 I ω 2 [J], where E is the

Harnessing Flywheel Torque: Maximizing Angular

Apr 13, 2025 · Moment of inertia, a measure of an object''s mass distribution, determines its momentum. Torque, a force applied to an object''s axis of rotation, generates angular

Motor Generator

The motor generator (MG) is an electric machine generates a shear stress on the magnetically active surface of the rotor that creates torque on the rotor. This surface is illustrated in Fig.

Modeling flywheel energy storage system

May 29, 2020 · Abstract and Figures Energy storage technologies are of great practical importance in electrical grids where renewable energy sources are

Flywheel Storage Systems | SpringerLink

Dec 17, 2019 · The components of a flywheel energy storage systems are shown schematically in Fig. 5.4. The main component is a rotating mass that is held via magnetic bearings and

Flywheel Energy Storage for Grid and Industrial

Flywheel Energy Storage Nova Spin included in TIME''s Best Inventions of 2024 List We''re thrilled to be one of the few selected in the Green Energy category

Modeling Methodology of Flywheel Energy Storage System

Sep 30, 2022 · The motor generates higher torque, which drives the flywheel at a higher rotational speed. Hence, the flywheel stores the energy kinetically, which is proportional to the square of

What Is A Flywheel, Its Diagram and Functions?

Oct 7, 2024 · The flywheel works this way: it first stores the mechanical energy that the torque generates, and then it releases this energy by rotating the

Design, modeling, and validation of a 0.5 kWh flywheel energy storage

Nov 1, 2024 · The flywheel energy storage system (FESS) has excellent power capacity and high conversion efficiency. It could be used as a mechanical battery in the

Generation of Free Energy using a Compact Flywheel

Mar 18, 2022 · A compact flywheel is involved in generation of free energy. The kinetic energy storage flywheel is designed to attach it to an electric machine. The mechanical bearings and

A Constant Power Discharge Strategy for Flywheel Energy Storage

Nov 8, 2024 · Flywheel energy storage system (FESS) possesses advantages such as rapid response, high frequency operation, and long lifespan, making it widely used in grid fr

Flywheel Energy Storage System

Flywheel Energy Storage Systems (FESS) are defined as systems that store energy by spinning a rotor at high speeds, converting the rotor''s rotational energy into electricity. They utilize a high

Flywheel energy storage systems: Review and simulation for

Dec 1, 2012 · Flywheel energy storage systems (FESSs) store mechanical energy in a rotating flywheel that convert into electrical energy by means of an electrical machine and vice versa

The Flywheel Energy Storage System: A Conceptual

Feb 16, 2024 · Abstract−While energy storage technologies cannot be considered sources of energy; they provide valuable contributions to enhance the stability, power quality and

The Status and Future of Flywheel Energy Storage

Jun 26, 2019 · The MG is either con-nected directly onto the flywheel rotor1 or is sometimes directly integrated with the flywheel rotor.2As with any storage technology, it is desirable to

Flywheel Energy Storage Calculator

The flywheel energy storage operating principle has many parallels with conventional battery-based energy storage. The flywheel goes through three

Flywheel energy storage

Jan 1, 2022 · A flywheel stores kinetic energy when a mass is rotated about a fixed axis, such mass being known as the rotor. Energy stored in the flywheel rises when the angular speed of

Energy Storage in Flywheels: An Overview

Jun 9, 2015 · Energy storage devices can help rectify the mismatch between generation and demand at any loading condition. Such devices can also provide some ancillary services, such

What is Flywheel Energy Storage? | Linquip

Apr 4, 2023 · Electric energy is supplied into flywheel energy storage systems (FESS) and stored as kinetic energy. Kinetic energy is defined as the "energy

The role of flywheel energy storage in

Aug 17, 2025 · The best choice is the lowest cost technology with low minutes of storage and flywheels fit this perfectly. A flywheel is a very simple device,

Flywheel energy storage

Aug 10, 2025 · These are: • In the absence of smooth continuous energy, to provide continuous smooth energy. For example, in reciprocating motors, flywheels are used because the torque

The Status and Future of Flywheel Energy Storage

Jun 19, 2019 · Electrical flywheels are kept spinning at a desired state of charge, and a more useful measure of performance is standby power loss, as opposed to rundown time. Standby

A review of control strategies for flywheel energy storage

Nov 1, 2022 · The flywheel energy storage system (FESS) offers a fast dynamic response, high power and energy densities, high efficiency, good reliability, long lifetime and low maintenance

Flywheel Energy Storage Systems and Their

Apr 1, 2024 · This study gives a critical review of flywheel energy storage systems and their feasibility in various applications. Flywheel energy storage systems

SIMPLIFIED IMPLEMENTATION AND CONTROL OF A

Jul 14, 2021 · A grid en- ergy storage system has the ability to reduce power system oscillations and respond to load variations by either injecting or absorbing the required power [1]. In the

Flywheels | EBSCO Research Starters

Mar 29, 2025 · Flywheels consist of a heavy rotor that spins at high speeds, with energy being added through torque and released similarly to power mechanical loads. An everyday example

Flywheel Energy Storage | Energy Engineering

Sep 29, 2021 · The flywheel energy storage system is useful in converting mechanical energy to electric energy and back again with the help of fast

Technology: Flywheel Energy Storage

Oct 30, 2024 · Flywheel Energy Storage Systems (FESS) rely on a mechanical working principle: An electric motor is used to spin a rotor of high inertia up to 20,000-50,000 rpm. Electrical

Flywheel Energy Storage

Flywheel energy storage is defined as a method for storing electricity in the form of kinetic energy by spinning a flywheel at high speeds, which is facilitated by magnetic levitation in an

Overview of Flywheel Systems for Renewable Energy

Jan 9, 2025 · son in terms of specific power, specific energy, cycle life, self-discharge rate and efficiency can be found, for example, in [3]. Compared with other energy storage methods,

Flywheel technology generates DMU fuel savings

Jun 16, 2015 · The DDFlyTrain project sought to demonstrate the feasibility, operational fuel and energy savings, and economic investment case for the

6 FAQs about [Flywheel energy storage generates torque]

Could flywheels be the future of energy storage?

Flywheels, one of the earliest forms of energy storage, could play a significant role in the transformation of the electri-cal power system into one that is fully sustainable yet low cost.

How does a Flywheel energy storage system work?

A flywheel energy storage system works by applying a torque in the direction of rotation to speed up the rotor, and applying a torque in the reverse direction to slow it down. On one level, it is simple to implement and understand in comparison with many other energy storage methods, and can store and release energy for potentially unlimited cycles.

Why does a flywheel speed up?

As more energy is imparted into a flywheel it speeds up as it stores more energy and slows down when it loses the said energy , . Although, the existing lithium-ion battery has a high energy density but high cost in term of power capacity and less power density.

How does a flywheel work?

In this way, the kinetic energy is converted back into electrical energy, and the flying wheel acts as a mechanical battery. Often, the mass used in the flywheel is shaped like a hollow cylinder . Fig. 6 shows the configuration of the prototype FES using a conventional induction motor and ball bearings.

How much energy does a flywheel store?

Indeed, the development of high strength, low-density carbon fiber composites (CFCs) in the 1970s generated renewed interest in flywheel energy storage. Based on design strengths typically used in commercial flywheels, σmax /ρ is around 600 kNm/kg for CFC, whereas for wrought flywheel steels, it is around 75 kNm/kg.

What is a Flywheel Energy Storage System (FESS)?

A Flywheel Energy Storage System (FESS) is defined as a system that stores energy for a distinct period of time to be retrieved later. There is a class distinction between flywheels used for smoothing the intermittent output of an engine or load on a machine and these energy storage systems.

Industry Information

- Nordic Energy Storage Mobile Power Supply

- Solar Air Conditioning System Installation

- High quality switchgear equipment in China company

- Best solar power station for sale Factory

- China Mobile s energy storage base station

- Large-scale energy storage in Brazil

- Tunisia solar panel photovoltaic panel manufacturer

- China al hassan switchgear for sale Buyer

- 5kw sunsynk inverter for sale in Melbourne

- Communication base station wind power maintenance improvement

- Tool batteries and prices

- Best sf6 circuit breaker for sale Wholesaler

- Wholesale c20 circuit breaker in Costa-Rica

- Aarhus Denmark introduces new energy storage policy

- Bogota rooftop photovoltaic energy storage

- China-Africa Smart Energy Storage Device

- Is it okay to install an outdoor power supply on the car

- Which BMS battery management system is the best in Kazakhstan

- Photovoltaic glass prices rebound

- How long does it usually take to charge a portable power bank

- Hot sale home circuit breaker for sale supplier

- High quality wholesale 16 kw deye inverter supplier

- South Ossetia p-type photovoltaic panel manufacturer

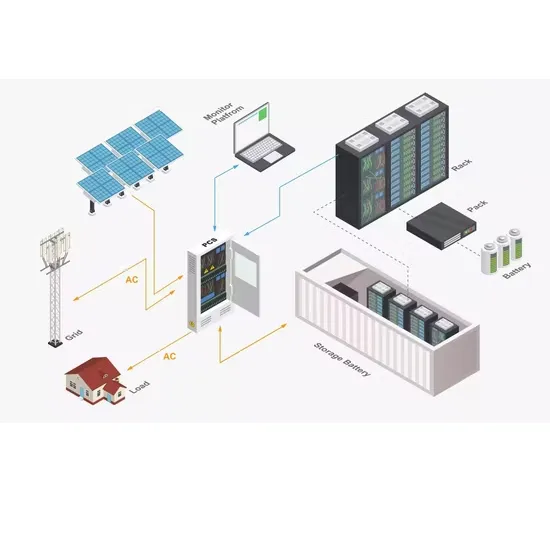

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.