DIY LiFePO4 Battery Pack: Step-by-Step Guide (2025 Update

Apr 18, 2025 · How to Build a LiFePO4 Battery Pack: DIY Guide with Expert Tips (2025) Why Build a LiFePO4 Battery Pack? LiFePO4 (Lithium Iron Phosphate) batteries dominate

Battery Pack Design | Dragonfly Energy

Our dedication to safety led us to employ lithium iron phosphate (LiFePO4) in our battery pack design. Also known as LFP, this chemistry is renowned for its

Tesla Patents Low-Cost LFP Battery

Jan 17, 2025 · Lithium iron phosphate or LFP is at the heart of new technologies for electric vehicle manufacturers. Now, Tesla has developed a potentially

The Manufacturing Process Behind Lithium Iron Phosphate Battery

Nov 13, 2024 · As the demand for reliable and long-lasting energy storage solutions continues to rise, the manufacturing processes for lithium iron phosphate battery cells are expected to

Lithium ion Battery Manufacturers in Pune, India,

BENTORK INDUSTRIES is a leading manufacturer of Lithium-ion and Lithium Ferro Phosphate (LFP) battery packs in India. One of the most well-known

Lithium Iron Phosphate (LiFePO4) Battery Manufacturing

Aug 18, 2025 · In this blog post, we will explore the complex and fascinating process involved in manufacturing LiFePO4 batteries. The Raw Materials: The journey to creating a LiFePO4

The Manufacturing Process Behind Lithium Iron Phosphate Battery

Nov 13, 2024 · Summary In conclusion, the manufacturing process of lithium iron phosphate battery cells is a complex and intricate sequence of steps that require precise control,

Top 12 LiFePO4 Battery Manufacturers in the

The demand for lithium iron phosphate (LiFePO4) batteries has surged in recent years due to their exceptional safety, thermal stability, long lifespan, and eco

KNOWLEDGE PAPER ON LITHIUM-ION BATTERY

Jan 22, 2024 · Diferent shapes of the lithium-ion cell Nomenclature of lithium-ion cell/battery Overview of Li-ion battery packs Assembling Process Detailed flowchart for Li-ion battery pack

LFP Battery Manufacturing Process: Components

May 16, 2024 · Overview of LFP Battery Components and Materials Lithium iron phosphate (LFP) batteries, a kind of lithium-ion battery, have obtained

LiFePO4 Cells Pack Assembly Line

Sep 13, 2024 · LiFePO4 Cells Pack Assembly Line: Optimizing the Manufacturing Process for Lithium Iron Phosphate Batteries As demand for safer, more efficient, and durable energy

Bayesian Monte Carlo-assisted life cycle assessment of lithium iron

Dec 13, 2024 · To address this issue and quantify uncertainties in the evaluation of EV battery production, based on the foreground data of the lithium-iron-phosphate battery pack

How Lithium Iron Phosphate Batteries Are Made

May 6, 2025 · Explore how lithium iron phosphate batteries are made, from synthesizing raw materials to cell assembly, electrolyte filling, formation cycling, and final quality control.

How Is the Manufacturing Process of Lithium Iron Phosphate Batteries

Feb 21, 2025 · The manufacturing process of lithium iron phosphate (LiFePO4) batteries involves several critical steps that ensure high performance and safety. These batteries are known for

ULBS

ULBS uses CATL Lithium Iron Phosphate (LiFePO₄) cells in our upgraded battery solutions. These battery packs allow end-users to upgrade their existing

Top 10 Lithium Iron Phosphate (LFP) Battery

Apr 28, 2024 · Compare the best LiFePO4/LFP battery manufacturers worldwide. Explore safety certifications, technical specs, and how to choose reliable

Custom LiFePo4 Battery Pack Manufacturing

Alexander Battery Technologies is an expert custom LiFePO4 battery pack manufacturer. We design and produce high quality customised Lithium Iron

Lithium Iron Phosphate Battery

The lithium iron phosphate battery (LiFePO4 battery) or LFP battery (lithium ferrophosphate) is a type of lithium-ion battery using lithium iron phosphate (LiFePO4) as the cathode material, and

Lithium EV Battery Pack and E Rickshaw Battery

Lithium India - Lithium EV Battery Pack, E Rickshaw Battery & Car Batteries Manufacturer from Pune, Maharashtra, India

Lithium-Ion Battery Assembly Process & Key

May 17, 2025 · Discover the key stages in the lithium-ion battery assembly process, from raw materials to pack assembly. Learn how battery-making

Status and prospects of lithium iron phosphate manufacturing

Sep 23, 2024 · Lithium iron phosphate (LiFePO4, LFP) has long been a key player in the lithium battery industry for its exceptional stability, safety, and cost-effectiven

LiFePO4 Cells Pack Assembly Line

Sep 13, 2024 · ALiFePO4 cells pack assembly line automates the process of assembling individual LiFePO4 cells into battery packs, ensuring consistency, precision, and efficiency.

Industrial preparation method of lithium iron

Industrial preparation method of lithium iron phosphate (LFP) Lithium iron phosphate (LiFePO4) has the advantages of environmental friendliness, low

8 LFP Battery Companies to Watch

Dec 20, 2022 · Lithium iron phosphate (LFP) batteries are a type of lithium-ion battery that has gained popularity in recent years due to their high energy

LFP Battery Production: Innovations

Jun 19, 2025 · Discover how one-pot synthesis and metal-to-cathode processes revolutionize lithium iron phosphate battery production with superior efficiency.

Custom Lithium Iron Phosphate (LFP) Battery Pack

Emerging Power is your premier lithium battery assembler. We manufacture custom lithium iron phosphate battery packs and assemblies for many

Lithium-ion Battery Pack Manufacturing Process

Jul 28, 2023 · This guide discussed the lithium battery pack anufacturing process, battery pack design, and the impact of technological advancements.

Lithium Battery Manufacturing Process Step-by

Aug 4, 2025 · Lithium Iron Phosphate (LiFePO₄): Excellent safety and long life, ideal for energy storage systems and electric vehicles. 3. 18650 and

Drakor & Anime Terpopuler

Setelah lebih dari satu dekade sejak film terakhirnya, waralaba Final Destination kembali hadir dengan wajah baru yang mengerikan lewat Final Destination:

TOP 10 Lithium Iron Phosphate Power Battery

Jan 10, 2022 · By November 2021, the installed capacity of Lithium iron phosphate batteries in China has reached 64.8GWh, accounting for 50.5% of

Top 10 LFP Battery Cell Manufacturers in China

Apr 9, 2024 · Ganfeng specializes in lithium resources SVOLT provides customized LFP solutions Keheng LFP battery performance Overview of

Manufacturing process of lithium iron

The manufacturing process of lithium iron phosphate batteries covers everything from the preparation of electrode materials to battery assembly and

Top 6 Canadian Lithium Battery Manufacturers

Discover Top Canadian Lithium Battery Manufacturers, key supply chain hubs, and essential industry fairs in 2024.

6 FAQs about [Manufacturing lithium iron phosphate battery pack]

Are lithium iron phosphate batteries better than other lithium ion chemistries?

Despite having a lower energy density than other lithium-ion chemistries, lithium iron phosphate batteries can provide better power density and longer life cycles. Emerging Power is your premier lithium battery assembler. We manufacture custom lithium iron phosphate battery packs and assemblies for many applications.

What is the production process of lithium iron phosphate (LFP) batteries?

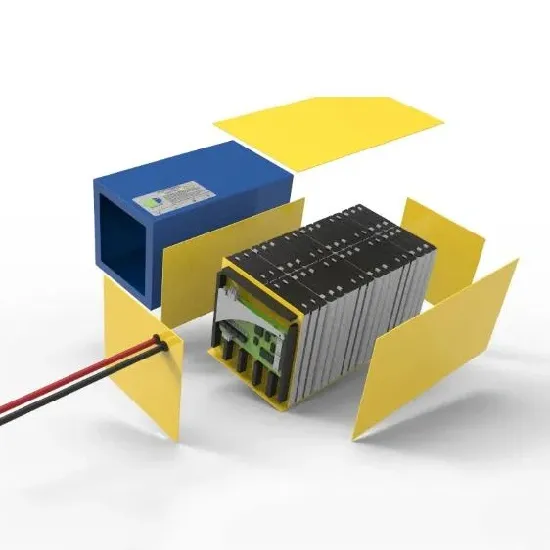

The production procedure of Lithium Iron Phosphate (LFP) batteries involves a number of precise actions, each essential to guaranteeing the battery’s efficiency, security, and long life. The procedure can be broadly divided into material prep work, electrode fabrication, cell setting up, electrolyte filling, and development biking.

What is a rechargeable lithium iron phosphate battery?

Rechargeable lithium iron phosphate batteries use LiFePO 4 as the principle cathode material. Despite having a lower energy density than other lithium-ion chemistries, lithium iron phosphate batteries can provide better power density and longer life cycles. Emerging Power is your premier lithium battery assembler.

Why is quality control important for lithium iron phosphate (LFP) batteries?

Quality control and testing are essential components in the manufacturing procedure of Lithium Iron Phosphate (LFP) batteries. Provided the high demand for reliability and performance, it is imperative to ensure that every stage of production meets rigorous quality standards.

What is lithium iron phosphate (LFP)?

Lithium iron phosphate (LiFePO 4), also called LFP, is one of the more recently-developed rechargeable battery chemistries and is a variation of lithium-ion chemistry. Rechargeable lithium iron phosphate batteries use LiFePO 4 as the principle cathode material.

Is lithium iron phosphate a good cathode material?

Lithium iron phosphate (LiFePO 4, LFP) has long been a key player in the lithium battery industry for its exceptional stability, safety, and cost-effectiveness as a cathode material.

Industry Information

- What brand of monocrystalline photovoltaic panels is good

- How many watts is 600w solar energy

- China thermal circuit breaker in Brazil

- 9v photovoltaic panel size

- Jamaica Photovoltaic Container BESS

- Is the new energy battery cabinet alkaline

- What is the current status of China s 5G base stations

- Cote d Ivoire energy storage battery price

- Nepal Energy Storage Power Engineering Company

- How much does a Swiss high frequency inverter cost

- Oceania Communication Base Station Super Capacitor Construction

- Cote d Ivoire outdoor power supply solar charging current limiting function

- 314ah energy storage battery

- Wholesale substation breaker in Lisbon

- Energy storage containers and prefabricated boxes

- Danish Aarhus lithium battery 3 7v cylindrical

- Türkiye energy storage battery recommendation

- Nouakchott Agent Solar Air Conditioning

- Soc balance control of energy storage power station

- Pv breaker isolator for sale in Croatia

- Senegal container manufacturers wholesale

- Technology section on wind power generation and energy storage

- Rate characteristics of all-vanadium liquid flow battery

Commercial & Industrial Solar Storage Market Growth

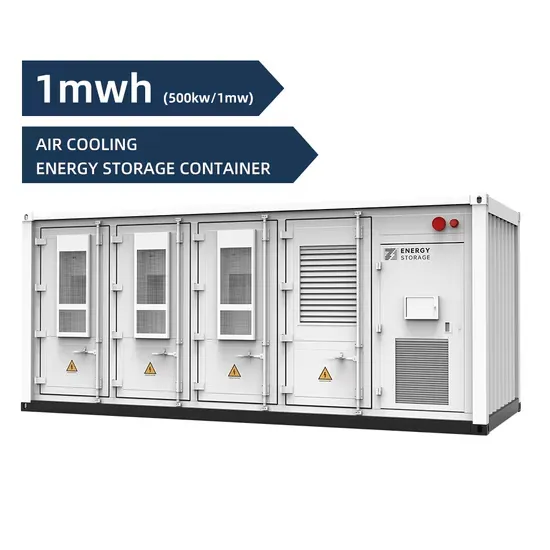

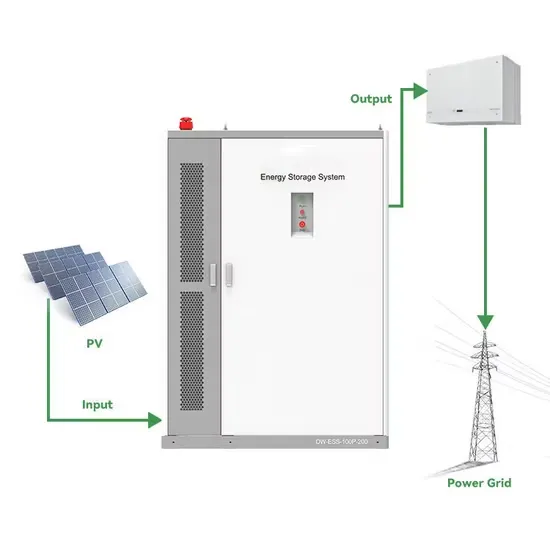

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.