Properties of polycrystalline silicon cell

Oct 26, 2018 · Polycrystalline silicon is a material composed of multiple misaligned silicon crystals. It serves as an intermediate between amorphous

هيكل الخلايا الشمسية متعددة البلورات

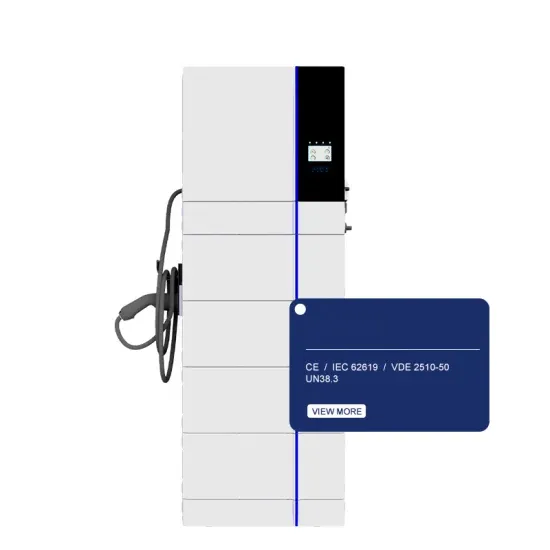

EK ENERGY تقدم تقنيات متقدمة تشمل عاكسات الطاقة، وحدات الطاقة المتكاملة، وبطاريات التخزين عالية الأداء لتوليد وتخزين الطاقة الشمسية بفعالية.

Emerging photovoltaic materials and technologies

Feb 3, 2025 · Emerging PV technologies include perovskite photovoltaic, OPV, and QDPV technologies, all of which are thin-film photovoltaic technologies. They all have the thin-film PV

Price volatility, human rights, and decarbonization

Aug 1, 2023 · Other module components like glass, junction boxes, aluminum frames, encapsulants, and backsheet are also mostly made in China. Even within China there are only

Polysilicon Production

The production and purification of polysilicon is the first step in the manufacturing process to produce conventional silicon solar cells. The fabrication of

The Role of Polysilicon in the Solar PV Industry A

Polysilicon — a purified version of silicon — is the main input to produce solar-grade polysilicon wafers (the building blocks of PV cells). These wafers utilize

Non Standard

The glass forms the front end of photovoltaic module and protects components housed within the laminate from the weather and mechanical stresses. At the

cairoglass

Vision Utilize glass expertise and experience to produce glass in line with international standard and code of practice in safe and environmental friendly

OPIS Solar Weekly | Solar Panel Materials Pricing

OPIS Solar Weekly provides trusted price assessments and current market news on solar materials production in Asia, the EU and the US, from upstream

Non Standard

The glass forms the front end of photovoltaic module and protects components housed within the laminate from the weather and mechanical stresses. At the same time serves as carrier

Ingots & Wafers | Solar Value Chain

Processing wafers is wedged between polysilicon production and cell manufacturing. Consequently, it is a fierce battleground that will see more consolidation in future years.

What Is Polysilicon and What Is It Used For?

Jan 5, 2024 · Polysilicon is a core material that serves as the backbone of various vital technologies. Polysilicon is used for fabricating ICs and making solar cells.

PV spot price

6 days ago · InfoLink Consulting provides weekly updates on PV spot prices, covering module price, cell price, wafer price, and polysilicon price. Learn about photovoltaic panel price trends

What is polysilicon and how is it made? —

Mar 14, 2024 · What is polysilicon? Polysilicon definition: Polycrystalline silicon, commonly shortened to polysilicon, is a purified form of silicon that includes p

Cairo non-standard photovoltaic glass components polysilicon

Can polysilicon junctions transform the silicon PV industry? The integration of polysilicon (poly-Si) passivated junctions into crystalline silicon solar cells is poised to become the next major

Summary of a Preliminary Feasibility Study on Cells

Aug 8, 2024 · The project aims to produce photovoltaic solar panels, starting from Egyptian quartz, metal silicon, and poly silicon, moving to solar cells, molds, and strips then to the

Monocrystalline Solar Modules for PV Projects

3 days ago · Targray''s extensive portfolio of high-efficiency monocrystalline solar modules is built to provide EPCs, installers, contractors and solar PV

Changes in the proportion of BoM and China''s overseas

Sep 25, 2024 · Production cost structure (202309 VS 202409) The cost structure of the PV industry has changed significantly since 2023. In September 2023, polysilicon accounted for

PV manufacturers''non-China production expansions

Apr 16, 2024 · As one of the crucial hubs supplying the U.S. PV demand, Southeast Asia still faces the most obstacles in exporting modules to the U.S. under the Uyghur Forced Labor

Environmental Effects of Technological

Jul 15, 2022 · Therefore, we construct a polysilicon PV system''s whole life cycle carbon emission model by applying the LCA method and further building the

World Bank Document

4 days ago · Local Manufacturing Potential for Solar Technology Components in Egypt MIDDLE EAST AND NORTH AFRICA ENERGY AND EXTRACTIVES GLOBAL PRACTICE THE

A Polysilicon Learning Curve and the Material

Jul 21, 2022 · Herein, the current and future projected polysilicon demand for the photovoltaic (PV) industry toward broad electrification scenarios with 63.4 TW

Polysilicon vs. Various Types of Silicon Materials,

In semiconductors, polysilicon applications are applied in wafer manufacturing, while silicon wafers are used in electronic circuits and solar cells. Polysilicon

Polysilicon Price: Chart, Forecast, History

Jun 29, 2020 · Track the current movement of the polysilicon spot price in our chart ️ Read our 2021 price forecast ️ View the price history ️ since 1981!

Upgraded metallurgical grade silicon and polysilicon for

Oct 1, 2021 · Solar grade silicon (SoGSi) is a key material for the development of crystalline silicon photovoltaics (PV), which is expected to reach the tera-watt level in the next years and

What you need to know about polysilicon and

Oct 13, 2021 · Polysilicon, a high-purity form of silicon, is a key raw material in the solar photovoltaic (PV) supply chain. To produce solar modules, polysilicon is

Solar PV and carbon border pricing mechanisms,

Jul 22, 2024 · One is the expansion of the most energy-intensive components of the solar supply chain (polysilicon, ingots and wafers) in regions where power

World Bank Document

6 days ago · This study concentrates on Egypt and attempts to identify strategic challenges and provide detailed recommendations for developing a local solar industry for selected

Polysilicon prices decline amid rising inventories, weak demand – pv

Nov 15, 2024 · Sources indicate the stagnation in global polysilicon spot trading over the past few months, coupled with the non-renewal of expired long-term procurement agreements, has

Photovoltaics Manufacturing, Polysilicon | Solar Power

PV manufacturing includes three distinct processes: 1. Manufacturing silicon (polysilicon or solar-grade), 2. wafers (mono- or polycrystalline) and 3. cells and modules (crystalline and thin-film).

New glass production project to support renewable energy

Nov 28, 2024 · The project will cover an area of 500,000 square meters, with total investments amounting to $300 million, and is set to build two production lines—one for flat glass with a

About Us | Cairo Glass

The idea of patterned glass factory establishment has been created by Mr.Siag, Mr. Saber, and Mr. Gouda the main shareholders of Cairo glass manufacturing co. We have developed the

6 FAQs about [Cairo non-standard photovoltaic glass components polysilicon]

Can polysilicon be used for solar energy generation?

These wafers utilize the photovoltaic effect to turn sunlight into electricity, meaning that polysilicon is useful for solar energy generation. It starts with the refinement of metallurgical-grade silicon into high-purity polysilicon for solar applications. The pure silicon is then cast into ingots, which are sliced into thin wafers.

Why is polysilicon important in solar PV?

As part of this global transition to renewable power, energy from solar is leading the charge and polysilicon in the solar PV is critical to facilitate this transition to renewable energy. Polysilicon, the most relevant raw material in the production of photovoltaic (PV) cells, is critical for producing solar panels that are reliable and efficient.

How does the price of polysilicon affect the cost of solar panels?

Fluctuations in cost: The price of polysilicon is impacted by market demand and production costs, which impacts the affordability of solar panels. However, addressing these challenges is essential in providing a stable and sustainable supply of solar energy. Conclusion

What are thin-film solar cells?

Over the past two decades, amorphous silicon, copper indium gallium selenide (CIGS), and cadmium telluride (CdTe) thin-film solar cells have pioneered industrialization in the competition of thin-film solar cells. Typically, thin-film solar cells must pass through three critical stages to achieve large-scale commercial applications.

Who makes perovskite solar cells?

Oxford PV in the UK, a well-known company in perovskite solar cells, has made important breakthroughs in the research of high-efficient and stable single-junction cells and perovskite-based tandem solar cells.

Are thin-film solar cells a competitive strategy?

Amorphous silicon, CIGS, and CdTe thin-film solar cells, in their exploration towards industrialization, have historically and currently regarded BIPV as a differentiation competitive strategy. However, with the progress of crystalline silicon technology, the advantages of thin-film solar cells in this segment are gradually diminishing.

Industry Information

- 6V inverter to 220V

- Vilnius container communication base station battery

- Can tool lithium batteries be combined

- There are several regulations related to battery energy storage systems for communication base stations

- 100W battery energy storage

- Photovoltaic panels installed for home use in Lisbon

- Wholesale breaker with outlet in Guyana

- Photovoltaic energy storage pvssyst

- Huawei West Africa cylindrical battery pack customization

- High quality bess battery storage in China for sale

- Hungarian ups energy storage battery

- Fiji containerized energy storage cabinet manufacturer

- Backup energy storage power supply

- Breaker distribution in China in Australia

- Spanish Omda outdoor power supply

- Photovoltaic 670 panel size

- Huawei Croatia photovoltaic panels

- Phnom Penh Sunshine Energy Storage Power Wholesale Price

- Eastern European Energy Storage Photovoltaic Power Generation Industry

- Solar power station for home in Congo

- North American Energy Storage Power Supply Industrial Design

- Tajikistan container communication base station battery maintenance site

- Can a 72 volt inverter be used with a 60 volt one

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

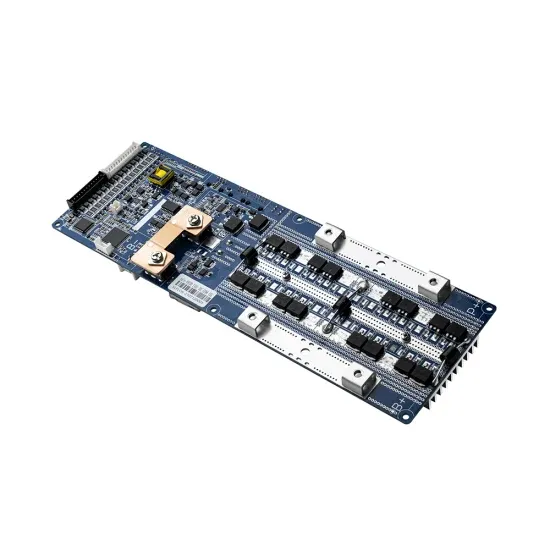

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.