Charging a Capacitor in Inverter:

Charging a Capacitor in Inverter - Inverters are static power converters for converting dc to ac. By controlling the conducting periods of the thyristors it is

DC Link Capacitors Selection and Arrangement Procedure in

Dec 28, 2023 · The most important parasitic elements in high-power inverters are the ones associated with the DC-link and the capacitors used in its structure. This article wi

analytical

Jan 3, 2024 · The DC link capacitor is an important component in a three-level inverter. Selection of appropriate DC link capacitor is a critical step in the design of a three-level inverter [2].

ESR and capacitance monitoring of a dc-link capacitor used

Sep 1, 2018 · In [44] the authors have calculated ESR and capacitance independently by calculating the impedance at difference frequencies for a three-phase PWM inverter with a

Using YMIN Capacitors in DC/DC Converter

Feb 3, 2025 · Capacitors are essential discrete components used in various power conversion applications, such as renewables for DC/DC converter

CSEE JOURNAL OF POWER AND ENERGY SYSTEMS, VOL.

Jan 13, 2023 · Abstract—In this paper, a new generalized step-up multilevel DC-AC converter is proposed, which is suitable for applications with low-voltage input sources, such as

ESR and capacitance monitoring of a dc-link capacitor used

Sep 1, 2018 · This paper presents a condition monitoring method of a dc-link capacitor used in a three-phase PWM inverter with a front-end diode rectifier intended for motor drives.

Inverter capacitor precharge procedure

Oct 23, 2022 · The device protects the battery management system (BMS) from damage caused by the initial current spike that is created when connecting directly to the large capacitors (> 5

How to Select DC Link Capacitor

The DC link capacitor is placed between the DC (in this case, the battery) and the AC (which is the load side) of the voltage inverter. The capacitor is placed

Analysis of dc-link capacitor current in three-level

Dec 22, 2020 · An essential part of ML inverter design is the selection of dc-link capacitors. The capacitors are a sensitive element of the inverter and a common source of failures. Capacitor

Selection of DC bus capacitors for solar inverters

May 24, 2024 · For T-type three-level solar inverters, in order to achieve balance of DC bus voltage and improve power supply quality, DC bus capacitors are widely used in the industry,

Selecting and Applying DC Link Bus Capacitors for

Oct 15, 2021 · Sam G. Parler, Jr., P.E. Cornell Dubilier Abstract, aluminum electrolytic and DC film capacitors are widely used in all types of inverter power systems, from variable-speed drives

Enhancing Inverter Efficiencies in Renewable

Mar 1, 2025 · This lands on the upper end of the reliability spectrum, ensuring more robust inverter performance. Ideally, the capacitors will be operating well

Top Signs Your Inverter Capacitor Needs

Aug 19, 2025 · This article delves into the role of the inverter capacitor in power systems, its types, common symptoms indicating the fault, and how to

Capacitors for Inverter Applications

Sep 20, 2018 · DC Link CDE ofers the most advanced metallized film technology for long life and high reliability in DC link applications. Available in a variety of package styles, our technology

DC Link Capacitor Calculation for Inverter

Oct 5, 2024 · Learn how to calculate the DC link capacitor for inverters, taking into account power rating, voltage ripple, switching frequency, and load dynamics. Ensure your inverter operates

DC-Link Capacitor RMS Current of CHB Inverter Under Open

Jan 17, 2024 · In this study, the influence of open-switch failures on the DC-link capacitor, a component prone to failures in power converters, is explored. The DC-link capacitor current in

Power Film Capacitor Application Guide

Oct 5, 2021 · The result of "clearing" is a tiny amount of capacitance loss while allowing the capacitor to continue to operate without any adverse efects. If a condition arises that causes

Selecting and Applying DC Link Bus Capacitors

Aug 2, 2021 · Aluminum electrolytic and DC film capacitors are widely used in all types of inverter power systems, from variable-speed drives to welders, UPS

Inverter DC Link Capacitor Selection

Sep 10, 2019 · Properly sizing the DC link capacitor for a three phase inverter seems to be a skill that evades most power electronic engineers. The objective of this article is to help you better

Capacitors for High Power

Mar 21, 2024 · DC Film The DC-link capacitor''s purpose is to provide a more stable DC voltage, limiting fluctuations as the inverter sporadically demands heavy current. A design can use

CAPACITORS

Oct 20, 2021 · Grid tie inverters require filter components in two key areas: The DC bus and AC output. The AC output filter is a low pass filter (LPF) that blocks high frequency PWM currents

Selecting dc-link capacitors for inverters

Feb 9, 2021 · Examine a dc link capacitor''s ac ripple current and you''ll realize it arises from two main contributors: the incoming current from the energy

Inverter DC Link Capacitor Selection

Nov 4, 2020 · Properly dimensioning the DC link capacitor for a three phase inverter seems to be a skill that evades a lot of power electronic engineers.

Minimizing DC Capacitor Current Ripple and DC

Jun 5, 2024 · Abstract -- This paper presents an accurate theory of calculating the DC link capacitor voltage ripples (Ampere-Second) and current ripples (Irms) for inverters and PWM

Selecting and Applying DC Link Bus Capacitors for

May 16, 2023 · Figure 1 shows some of Cornell Dubilier''s DC Link capacitors for power inverters. Left photo features aluminum electrolytic capacitors of snap-in, plug-in, and screw-terminal

Minimum DC Link Capacitance Calculation | True Geometry''s

Feb 7, 2025 · Q: How does the modulation index affect the DC link capacitor requirement? A: Higher modulation indices lead to larger ripple currents, requiring a larger DC link capacitor to

Example : Simulation

May 9, 2013 · Step 1: Open a new schematic design In this schematic you will place an inverter (symbol of the schematic you created before) and add other components (a supply voltage

Power Film Capacitor Application Guide

May 6, 2024 · DC FILM CAPACITORS FOR POWER ELECTRONICS AN OVERVIEW Film capacitors are widely used in power electronics applications including but not limited to DC

Common Capacitors in Solar Power Conversion

Jun 20, 2024 · DC Link Capacitors: These capacitors smooth ripples during power conversion, store surplus energy and suppress voltage surges. DC links can

Distribution System Disturbances its Effects on Voltaged

Jan 31, 2020 · Add capacitors in steps to reduce the stored energy in the source inductance of the system. With this technique, capacitors are switched in via contacts at 10 - 25% increments,

Design and Control of Small DC-Link Capacitor-Based

Dec 1, 2019 · The conventional rectifier system for an inverter is shown in Figure 1. Diode rectifier systems generally utilize capacitors with large capacitances to stabilize the operation of the

Reveal the function and type of inverter

Jan 17, 2024 · This comprehensive guide aims to demystify the capacitor''s significance within inverters, exploring its functions, types, and the

EEC 116 Lecture #4: CMOS Inverter AC Characteristics

EEC 116 Lecture #4: CMOS Inverter AC Characteristics Rajeevan Amirtharajah University of California, Davis Jeff Parkhurst Intel Corporation

Minimum DC Link Capacitance Calculation | True Geometry''s

Feb 7, 2025 · This calculator determines the minimum DC link capacitor value required for an inverter supplying a given load, considering modulation index and ripple voltage.

How can I size the DC link capacitor of a 3 phase

Jul 20, 2017 · "DC link capacitor" is a common industry term for the bulk / bypass capacitance between the supply rails of a 3-phase inverter as used for motor

The strategy of second harmonic voltage match suppression for the DC

Apr 1, 2022 · Due to the DC–AC power coupling of single-phase inverter, the DC link is equipped with large capacity electrolytic capacitor in practical application. At the same time, the second

Selecting Capacitors for Inverter Applications

This paper will present a practical mathematical approach on how to properly size a bus link capacitor for a high performance hard switched DC to AC inverter using film capacitors and will

6 FAQs about [Add capacitor to the DC end of the inverter]

What is the role of a DC link capacitor in inverter systems?

Before diving into the calculations, it is important to understand the role of a DC link capacitor in inverter systems. The primary function of a DC link capacitor is to smooth out the DC bus voltage between the rectifier and inverter stages, which helps in reducing voltage ripple and preventing voltage spikes.

How do I choose the right capacitor for my inverter?

In practice, selecting the right capacitor for your inverter involves more than just calculating the required capacitance. Other factors to consider include: - Voltage Rating: The capacitor must have a voltage rating higher than the DC link voltage to prevent breakdown.

Why does a DC link capacitor have a ripple current ICAP?

We may infer from Figure 2 that the DC link capacitor’s AC ripple current Icap arises from two main contributors: (1) the incoming current from the energy source and (2) the current drawn by the inverter. Capacitors cannot pass DC current; thus, DC current only flows from the source to the inverter, bypassing the capacitor.

Does Adding capacitance improve the performance of an inverter?

So beyond a certain point, adding capacitance does little to enhance the performance of the inverter. = 308 uF That’s 16 times less capacitance than that of the electrolytic capacitor! Certainly packaging a 308 uF capacitor verses a 5,000uF capacitor makes for a smaller, lighter and more compact design.

What is a DC link capacitor?

Inverter design plays a pivotal role in many modern power electronics applications, from renewable energy systems to motor drives. One of the critical components in an inverter circuit is the DC link capacitor. This capacitor helps stabilize the DC voltage and minimize voltage ripple, ensuring efficient and reliable operation of the inverter.

How big should a DC link capacitor be?

With electric vehicles, inverters are typically optimized for two things - power density and efficiency. Thus, DC link should not be any larger than what the requirements call for. The objective of this article is to help you better understand the role of the DC link capacitor and how to properly size it based off your requirements.

Industry Information

- Togo wall mounted household energy storage battery

- Huawei outdoor energy storage power supply pcb board

- 260kwh energy storage battery

- Photovoltaic inverter mlpe

- Container adds solar energy system

- Kosovo 2025 Energy Storage Project

- Danish container manufacturers wholesale

- Vienna BESS sells new uninterruptible power supply price

- Reset circuit breaker factory in Turkmenistan

- Accra Energy Storage Battery Management System

- Should distributed photovoltaics be equipped with energy storage

- House circuit breaker factory in Kuala-Lumpur

- Universal inverter converts high voltage to low voltage

- UPS battery cabinet 1p circuit breaker

- Sucre Photovoltaic Power Generation and Energy Storage Investment and Construction

- EK Electric and Photovoltaic Inverter

- Solar panels can provide power for on-site energy

- Wholesale c16 circuit breaker in Korea

- Photovoltaic inverter single phase 15 kW

- Georgia power energy storage cabinet installation method

- Solar power system batteries in Colombia

- Latest electrochemical energy storage

- Indonesia adjusts battery storage fees

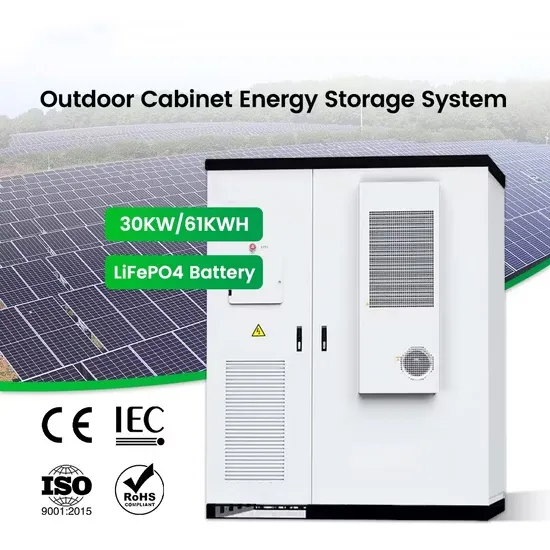

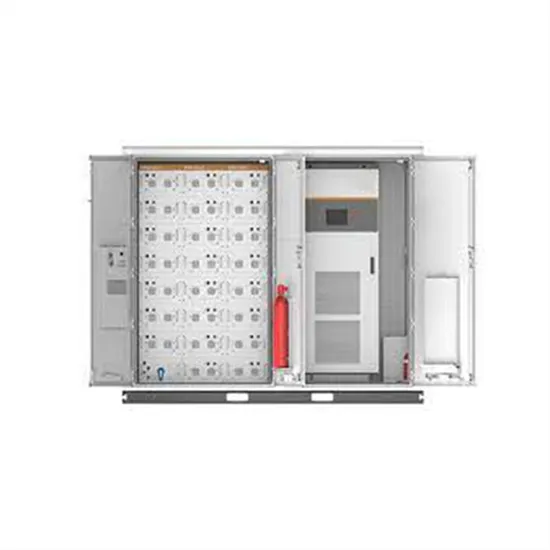

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.