What is the difference between a double-sided double-glass

May 22, 2025 · The production of N-type monocrystalline cells has higher requirements for silicon purity, doping process, cleaning and texturing, and the production cost is higher than that of P

Silicon substrate, Blank of Silicon, monocrystalline silicon

Jul 18, 2025 · Since light is easily scattered on the grain boundaries of polycrystalline materials, in order to improve the transmission rate of light and maximize the efficiency of the optical

Monocrystalline silicon: efficiency and

Sep 3, 2018 · In this way, impurities that would affect the uniformity of the glass are avoided. Compared to polycrystalline ingot molding, monocrystalline

Monocrystalline Silicon Tempered Double Glass

Jun 9, 2024 · Monocrystalline Silicon Tempered Double Glass Solar Roof Tile, Find Details and Price about Roofing Sheet Wholesale Roof Shingles from

Understanding Monocrystalline Solar

Apr 10, 2024 · They are typically made of monocrystalline silicon and have a double glass or transparent back sheet to allow

Monocrystalline Silicon Solar Module/Panel,

The products support customised designs such as single-sided, double-sided and double-glazed, with an output power of 560-605w. The non-destructive

A comparative life cycle assessment of silicon PV modules:

Sep 15, 2021 · Life Cycle Assessments (LCA) of single-crystalline silicon (sc-Si) photovoltaic (PV) systems often disregard novel module designs (e.g. glass-glass modules) and the fast pace of

Silicon Materials | SpringerLink

Nov 28, 2023 · Monocrystalline Si (mono-Si), also called as single crystalline Si, is one kind of crystalline Si grown on the basis of one single crystal seed. The material possesses the

Photovoltaic panel double glass monocrystalline silicon

Find your monocrystalline silicon photovoltaic module easily amongst the 421 products from the leading brands (Sharp, Risen, Sunowe,) on DirectIndustry, the industry specialist for your

Understanding Monocrystalline Solar Panels

Apr 10, 2024 · Monocrystalline solar panels are made from a single crystal of silicon, which is a semiconductor material that can convert sunlight into

How durable is the double-sided double-glass n-type monocrystalline

In addition, the use of N-type monocrystalline silicon wafers enables the module to maintain a high power generation efficiency even when the light conditions are weak, further extending

BIFACIAL SERIES – GLASS-TO-GLASS PHOTOVOLTAIC

Dec 4, 2012 · ECONOMICS Bifacial G2G technology is a turning point in photovoltaic (PV) system technology. It replaces costly single-axis and double-axis mechanical tracking systems with

monocrystalline silicon PV-翻译为中文-例句英语| Reverso

Feb 14, 2022 · 使用Reverso Context: Company independent research and development, quality and efficient Solar photovoltaic component, the main products are: monocrystalline silicon PV

Yixin PV_Monocrystalline silicon module,General components,Double glass

It adopts domestic advanced automatic production equipment and production management system, and has the ability to produce conventional modules, double glass modules, diamond

Monocrystalline solar panels: a comprehensive guide

Aug 30, 2024 · How is a monocrystalline solar panel made Monocrystalline panels are thin slabs typically composed of 30-70 photovoltaic cells assembled, soldered together, and covered by

Structural diagram of monocrystalline silicon

... basic components of double glass PV panel are shown in Figure 1, including cover glass, ethylene-vinylacetate (EVA), silicon solar cells, and back glass.

A comparative life cycle assessment of silicon PV modules:

Sep 15, 2021 · This study analyses two monofacial, single-crystalline silicon module designs: framed glass-backsheet (G-BS) and frameless glass-glass (G-G) design (layout given in Fig.

Monocrystalline silicon module_Products_Yixin PV

At present, the company''s main components such as large-size multi main grid half, double-sided double glass and high-efficiency half have considerable market competitive advantages in

Vertex_NEG21C.20_EN_2024_APAC_A_web

Mar 2, 2024 · N N-type i-TOPCon bifacial dual glass Monocrystalline module DIMENSIONS OF PV MODULE(mm) 33 1303 1303 1264

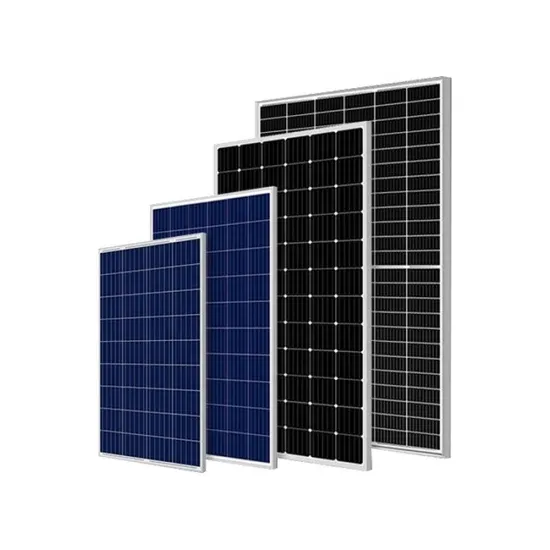

Monocrystalline vs Polycrystalline Solar Cells and How to

Mar 12, 2025 · Monocrystalline and polycrystalline silicon solar panels With the rapid development of solar photovoltaic energy storage, its solar panel technology update iteration is also very

Environmental impact assessment of the manufacture and

Sep 10, 2024 · Müller et al. (2021) investigated the changes in the environmental impact of silicon PV modules through single and double-sided glass PV module design, manufactured in

Essential Electronic Materials: Part 1

Aug 8, 2025 · 1 Introduction Silicon, a fundamental material in modern electronics, is essential in applications from integrated circuits to solar cells. As a

What is the structure of a double-sided double-glass n-type

First, the core part of the double-sided double-glass n-type monocrystalline solar photovoltaic module is the N-type monocrystalline silicon cell. This cell is made of high-purity N-type

Effect of grinding damage on cutting force and ductile

Nov 15, 2022 · Scratch experiment is an important way to study the removal mechanism of hard and brittle materials. In recent years, in order to analyze the grinding mechanism of brittle

Double-glass PV modules with silicone encapsulation

May 21, 2024 · Double-glass PV modules are emerging as a technology which can deliver excellent performance and excellent durability at a competitive cost. In this paper a

Monocrystalline Silicon Double Glass Cell Components

Summary: Monocrystalline silicon double glass cell components are transforming solar panel efficiency and durability. This article explores their technical advantages, industry applications,

What advantages does double glass solar

6 days ago · Compared with traditional monocrystalline silicon photovoltaic modules, double-glass double-sided modules have the advantages of a long

Structural diagram of monocrystalline silicon

Download scientific diagram | Structural diagram of monocrystalline silicon double glass photovoltaic panel. EVA: ethylene-vinylacetate. from publication:

Monocrystalline solar panels: the expert guide

Jul 25, 2025 · What are monocrystalline solar panels? Monocrystalline solar panels are made with wafers cut from a single silicon crystal ingot, which

The difference between monocrystalline silicon

May 24, 2024 · The magical silicon wafer that converts solar energy into electrical energy is the core of photovoltaic technology. Today, let''s take a closer look at

6 FAQs about [Monocrystalline silicon and double glass components]

How do monocrystalline solar panels work?

Monocrystalline solar panels are made from a single crystal of silicon, which is a semiconductor material that can convert sunlight into electrical energy. When sunlight hits the surface of the panel, it excites the electrons in the silicon atoms, causing them to move and create an electrical current.

What are monocrystalline solar panels?

Monocrystalline solar panels are a type of solar panel that has gained popularity in recent years due to their high efficiency and durability. They are made from a single crystal of silicon, which allows for the efficient movement of electrons through the panel.

What is a double glass c-Si PV module?

Recently several double-glass (also called glass–glass or dual-glass modules) c-Si PV modules have been launched on the market, many of them by major PV manufacturers. These modules use a sheet of tempered glass at the rear of the module instead of the conventional polymer-based backsheet. There are several reasons why this structure is appealing.

What are the advantages of monocrystalline solar panels?

High Efficiency: One of the primary advantages of monocrystalline solar panels is their high efficiency. They are able to convert a larger percentage of the sunlight that hits them into usable electricity, which means that they can generate more power per square foot than other types of solar panels.

Why is single crystalline silicon preferred over multi-crystalline silicon?

Single-crystalline silicon was chosen over multi-crystalline silicon as it is the leading polysilicon feedstock with a market share of 65% in 2019 and expected market share of 80% by 2030 .

Do single-Si glass-glass modules have more impact than glass-backsheet modules?

Single-Si glass-glass modules show lower impacts than glass-backsheet modules. Most impacts lowest for module production in EU, followed by Germany and China. Comparison of influence of different life cycle inventory datasets on results. Proposal of warranty-based yield calculation method for more exact impacts per kWh.

Industry Information

- Uninterruptible Power Supply for South Sudan Telecommunication Base Stations

- 15kw energy storage BESS

- Are there many applications for energy storage liquid cooling systems

- What should we do if the wind-solar hybrid power plant of a communication base station is shut down

- Swedish power photovoltaic folding container wholesale

- Three-phase sinusoidal pwm voltage inverter

- Energy storage temperature control system manufacturer in Sydney Australia

- Mbabane Solar PV Panels Company

- 1 watt 1 yuan solar panel

- 12v220v inverter with water pump

- Buenos Aires Energy Storage Fire Equipment Manufacturer

- South America Inverter Outdoor Manufacturer

- High-power inverter with reliable quality

- Belarus inverter sales price

- 5kwh battery storage for sale in Yemen

- How many watts are 50X100 solar panels

- Power Base Station Stocks

- Lithium battery pack voltage drops suddenly

- Ashgabat wind power storage battery

- How much does a gigabit outdoor base station cost

- Price of inverter in Nairobi

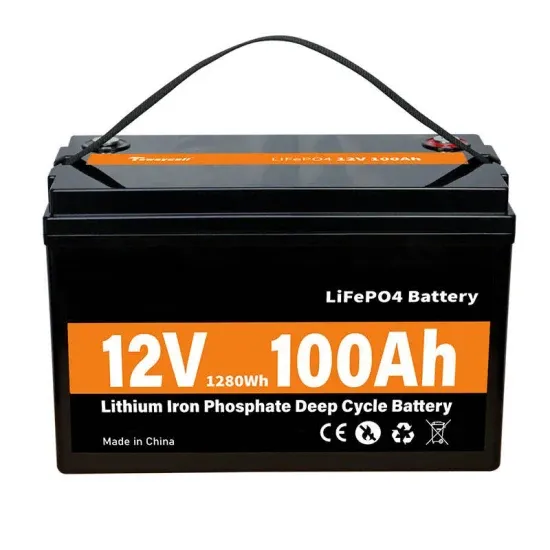

- Home 12V Energy Storage System

- Solar lithium battery 10 degree energy storage cabinet

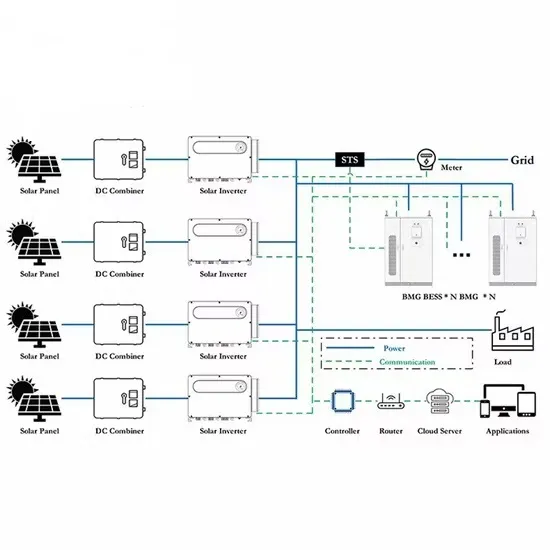

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.