一文读懂当前晶硅电池(PERC、TOPCon、HJT、N-IBC、P

Aug 4, 2022 · 在P型半导体材料上扩散磷元素,形成n+/p型结构的太阳电池即为P型电池片; 在N型半导体材料上注入硼元素,形成p+/n 型结构的太阳电池即为N型电池片。 P型电池制作工

PERC PV Cells and Components

The new technology of PERC passivation film effectively reduces the back surface load, increases the open circuit voltage, increases the back surface reflection, and improves the short circuit

Intuitive Comparison: PERC, TOPCon, HJT, BC,

In the photovoltaic field, battery technology is always a decisive factor in module performance, concerning not only the photovoltaic conversion efficiency but

Perc battery, what is PERC battery

Nov 9, 2024 · Perc battery (Rear Cell) is a structure of the battery. The earliest originated in the 1980s, in 1989, the research team of the University of New South Wales in Australia officially

PERC solar cell structure and preparation process thereof

An AlOx layer and a SiNx layer are successively deposited on the back surface of the cell piece body. On the basis of a conventional PERC cell preparation process, a surface oxidation

什么是PERC电池,PERC电池的优点跟缺点

Jun 5, 2025 · PERC (Passivated Emitter and Rear Cell)电池便是PERC电池德全称,接下来我们便详细来看看这一文:什么是PERC电池,PERC电池的优点跟缺点。 什么是PERC电池?

What type of battery is a PERC battery? | Company News

Feb 20, 2025 · PERC battery, short for "Passivated Emitter and Rear Contact" battery, is naturally derived from the conventional Aluminum Back Surface Field (BSF) battery structure.

Removing and Installing the Battery and Battery Cable

Dec 3, 2012 · This document contains information on removing and installing the battery, battery cable, and memory module on DellTM PowerEdgeTM Expandable RAID Controllers (PERC).

PERC Solar Cells

4 days ago · The PERC solar cell was first introduced by UNSW in 1983 and it claimed the world-record efficiency in 1989 [1]. The PERC concept was further improved by the usage of locally

Why the PERC photovoltaic solar photovoltaic application

Because the battery has a multilayer, solar photovoltaic web, photovoltaic (pv) grid, in the PERC need more steps in the production of photovoltaic cells, leading to higher costs. PERC is an

什么是PERC太阳能电池

Jun 24, 2021 · PERC太阳能组件在市场上不断增长,但PERC电池技术是什么,它的优势是什么?为了更好地理解 PERC 电池技术的重要性,让我们首先回顾一下标准硅太阳能电池板中常

(PDF) BATTERY MODULE AND PACK ASSEMBLY

Feb 6, 2019 · Our second brochure on the subject "Assembly process of a battery module and battery pack" deals with both battery module assembly and

The Difference Between Standard and PERC

Sep 7, 2018 · Solar cells convert sunlight (photons) directly into electricity through the photovoltaic effect. The cells can be used to power consumer products,

【光伏科普】刷屏朋友圈的"PERC技术"到底是什么?

Nov 30, 2018 · 不同电池的户外发电性能比较与分析仍在进行中。 4)PERC双面电池的出现再次提升了PERC电池的竞争力。 目前双面PERC电池的双面率

PERC Solar Cell Technology 2018 Edition

That''s why our PERC 2018 report is looking at PERC+, that''s for us everything supporting basic PERC to improve efficiency and yield – from selective

Perc battery assembly with high pid resistance and

Perc battery assembly with high pid resistance and preparation method therefor - Patent WO-2021036798-A1 - PubChem

Production Processes for Fabrication of Lithium

This chapter is intended to provide an overview of the various aspects of manufacturing lithium-ion (Li-Ion) cells. While the basic principles of cell

科普 | 什么是PERC电池?一文带你全面了解!(建议收藏)

Sep 4, 2024 · 劣势: PERC电池的理论效率极限相对较低(24.5%),且存在光致衰减问题,特别是在多晶PERC电池中更为明显。 技术成熟度: PERC技术已经非常成熟,但随着p型向n型

光伏技术科普:PERC结构电池工艺流程

Mar 7, 2024 · PERC电池的制备要经过硅片检测,制绒、扩散、刻蚀、氧化、背钝化、PECVD、背激光、丝网印刷、烧结、检测分选、包装。 【检测目的】:硅片是太阳能电池片的载体,硅

PERC: Controller learn cycle mode details and explanations

Dec 5, 2024 · When in Warning Only mode, the controller continues to prompt you to start the learn cycle every seven days until it is performed. Note: In PERC H700 and previous, virtual

WO/2021/036798 PERC BATTERY ASSEMBLY WITH HIGH PID

Disclosed are a PERC battery assembly with a high PID resistance and a preparation method therefor, relating to the technical field of solar cells. The battery assembly comprises a

总结下目前的主流光伏电池技术——PERC篇

Nov 14, 2022 · PERC电池的钝化膜最核心,所以进行钝化的薄膜沉淀工艺就是最核心步骤,相应的进行薄膜沉淀所需的 PECVD设备 和 ALD设备 就是最关键设备,这些设备在前些年一直也

解决DELL PERC H730P mini更换电池BBU后仍然显示

Mar 6, 2021 · 文章浏览阅读1w次,点赞2次,收藏18次。本文介绍了解决DELL R730服务器PERC730P阵列卡BBU电池故障的过程。通过更换电池并使用perccli工具进行校准,成功解决

Industrialized high-efficiency mono PERC cells

May 21, 2024 · Passivated emitter and rear cell (PERC) technology can significantly increase the absolute efficiency of PV cells by over 1.2%. Since PERC processing is also compatible with

PERC+电池的几种结构

May 31, 2021 · 提出了一种非常稀薄的PERC + POLO制造工艺,该工艺通过阴影掩膜通过a-Si指的PECVD沉积进行。 掩膜可沉积70μm窄且250 nm高的a-Si指形物,这些栅线形物可结晶成多

尚德科普丨一文搞懂PERC PERT PERL_搜狐汽车_搜

Jan 7, 2019 · 要搞清楚PERC、PERT、PERL的区别,首先要了解他们的历史。 PERC是一种高效电池结构。 最早起源于上世纪八十年代,1989年由澳洲新

总结下目前的主流光伏电池技术——PERC篇

Nov 14, 2022 · 图片来源:互联网查询 事实上,在P型衬底之上,PERC电池于BSF并无二致,最大的区别在背面—— 钝化膜。 这里先解释一下什么是钝化。之所以有钝化这个词,主要是硅

Current and future lithium-ion battery manufacturing

Apr 23, 2021 · Figure 1 introduces the current state-of-the-art battery manufacturing process, which includes three major parts: electrode preparation, cell assembly, and battery

新能源汽车电池装配

Jul 22, 2022 · 新能源汽车 (NEV) 电芯对热量敏感,必须安装在清洁的环境中。例如,焊接是一种常见的连接技术,但并不是一种可行的解决方案,因为它涉及

Battery Pack Manufacturing Process

Mar 15, 2025 · The battery module assembly process is a crucial step in the battery pack manufacturing process, where individual battery cells are

The Passivated Emitter and Rear Cell (PERC): From

Dec 1, 2015 · To enable manufacturers to move past the 20% cell energy conversion efficiency figure in production, high-efficiency PERC (Passivated Emitter and Rear Cell) sequences are

Innovating battery assembly

Aug 13, 2025 · Innovating battery assembly Solutions that bring productivity, quality, and sustainability in e-mobility and battery manufacturing to a new level

PERC太阳能电池原理、技术、生产流程、工艺流程详

Jul 23, 2018 · PERC (PassivatedEmitterandRearCell),即钝化发射极和背面电池技术,最早在1983年由澳大利亚科学家MartinGreen提出,目前正在成为太阳

DELL Perc H740p Mini Card With Battery

Aug 16, 2025 · Buy online $195.00 0878M-KIT DELL Perc H740p Mini Card With Battery Assembly KIT For DELL EMC Poweredge R640 / R740 / R740xd /

未来的领跑技术——PERC—solarbe索比太阳能光伏网

Jul 20, 2018 · PERC技术是未来太阳能光伏领域的关键创新,推动高效能源转换与可持续发展。

Industry Information

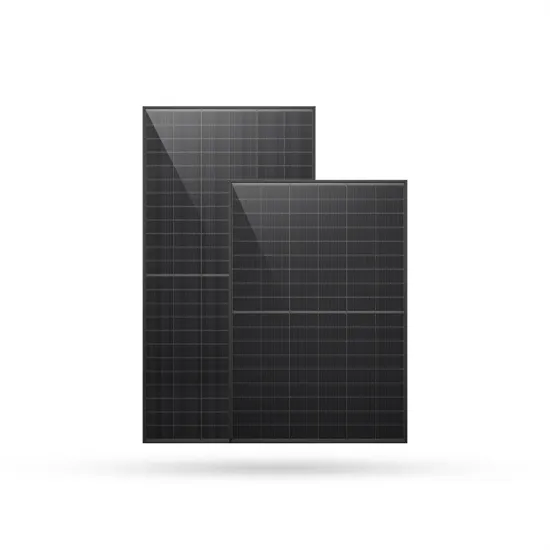

- All black component ctm

- The cost of installing green base stations in Kenya

- Ashgabat installs solar power generation system

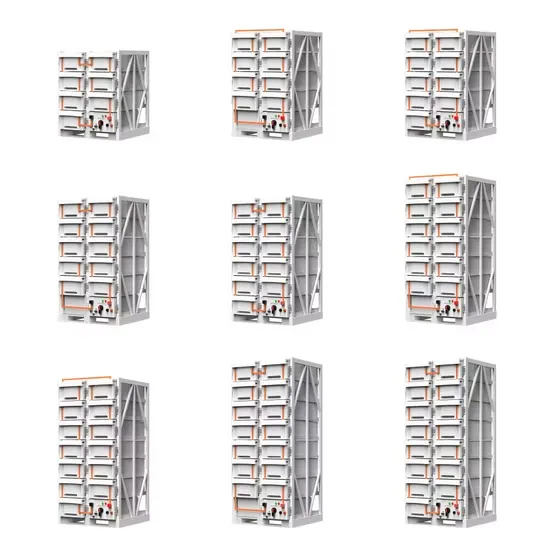

- Power storage cabinet technology

- Cyprus exports household photovoltaic panels

- Uninterruptible power supply box price

- 16kw sunsynk inverter factory in Brazil

- Best high quality on grid inverter Factory

- Off-grid power inverter

- Brief Introduction to EMS for Solar Base Stations

- Industrial switchgear factory in Turkey

- Are Ankara cylindrical lithium batteries reliable

- Price of thermal insulation photovoltaic tiles

- 10kv power station energy storage system

- Container energy storage lithium battery in Gothenburg Sweden

- Addis Ababa Mobile Power Station Generator Company

- South African container energy storage plant system

- Are there any 5G base stations in Vilnius

- Sao Tome Electric New Energy Storage Application

- RV Energy Storage Inverter

- Is there electricity on the communication base station tower

- Ecuador Energy One Energy Storage Battery Project

- What does inverter AC measurement mov mean

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.