Detection of connection faults and estimation of contact

Mar 1, 2025 · Connection faults between cells of a battery pack can lead to increased contact resistance (CR) and thus abnormal heating at the connections, which can seriously damage

Lithium Battery Internal Resistance and Its Impact

In evaluating battery performance, internal resistance (IR) is a critical factor, especially in lithium-ion batteries. It directly affects the battery''s efficiency, power output, and lifespan. Internal

What Is Thermal Runaway in Lithium Batteries

1 day ago · Thermal runaway in lithium batteries is a rapid, uncontrollable reaction causing extreme heat, fire, and toxic gas release, posing serious safety risks.

Lítium akkumulátorcsomag javítása egyszerű hibaelhárítási

Aug 11, 2025 · Kulcs elvezetések Regularly inspect lithium battery packs for signs like swelling, low voltage, or overheating to catch problems early and keep them safe. Use simple tests

LOW-VOLTAGE BATTERY PACK CONNECTOR

Mar 22, 2023 · ATTERY PACK EXTERNAL COMMUNICATION INTERFACE The battery pack external communication interface is for the battery management unit (BMU) to communicate

Influence of the connection topology on the performance of lithium

Sep 1, 2021 · In order to meet the energy and power requirements of large-scale battery applications, lithium-ion cells have to be electrically connected by various serial-parallel

Full-Tab Lithium Battery Cell Market

1 day ago · Full-tab cell producers are investing heavily in blockchain solutions for cobalt and lithium traceability, with initiatives like the Global Battery Alliance''s Battery Passport gaining

Electrical Connection Issues in Battery Packs

Mar 23, 2025 · Explore common electrical connection issues in battery packs and proven solutions from VADE Battery. Learn how reinforced joints, precision torque, and smart BMS

All Things You Need to Know about Internal

This article will introduce the basic knowledge of lithium battery internal resistance and explain how to measure the internal resistance of lithium batteries. Before

The Construction of the Li-ion Battery Pack

Jul 29, 2020 · The connection system is what transforms a cell into a battery pack. There must be a connection between the cell and the BMS in order to interface with each other. Nickel strips

Lithium battery connection solution

How to Connect Lithium Batteries in Parallel Safely? In order to prevent potential hazards and optimize battery performance, it is necessary to ensure the safe connection of lithium batteries

Master Lithium Battery Connections Safely

Mar 22, 2025 · Avoid hazards by learning correct lithium battery configurations. Ensure safety and performance by connecting cells in series, parallel, or both.

Lithium battery pack detection pin setting

The +0 is a high integration solution for lithium-ion/polymer battery protection. +0 contains internal power MOSFET, high-accuracy voltage detection circuits and delay circuits. +0

Microsoft Word

Nov 19, 2020 · XB7608AR contains advanced power MOSFET, high-accuracy voltage detection circuits and delay circuits. XB7608AR is put into an ultra-small CPC5 package and only one

BU-302: Series and Parallel Battery Configurations

BU-302: Configuraciones de Baterías en Serie y Paralelo (Español) Batteries achieve the desired operating voltage by connecting several cells in series;

Lithium battery module design production

Aug 18, 2025 · Lithium-ion battery pack internal connection wire is very much, manual welding operation step too many and welding, assembly and other

How to Connect Lithium Batteries in Series and

Jun 7, 2024 · We''ll explore the basics and provide detailed, step-by-step instructions on how to connect li-ion cells in series, parallel, and series-parallel

Lithium ion battery pack internal short circuit protection

Jan 29, 2025 · TE''s PPTC and HPP-TA family of products provide a possible solution to prevent the occurrence of a serious accident in the event of an internal short circuit in the power battery.

Custom Battery Packs: A Guide to Connectors

Apr 8, 2025 · Battery packs are designed to have fixed capacities and voltages to power specific applications for a required length of time before recharging. To

Connecting Lithium Batteries in Parallel and

How to Connect Lithium Batteries in Parallel and Series? Series connection increases battery voltage.Parellel connection increases battery capacity.

How to Measure Internal Resistance of a Battery

Feb 1, 2023 · It is important to monitor internal resistance to detect any performance degradation and predict battery failure, making it a crucial factor

KULR Technology Group | Thermal Management

1 day ago · With a rich 40-year heritage in advanced thermal management technologies, KULR creates safe, high-performance batteries for space,

Must-Have Sensors for EV Battery Packs & Cell

Aug 11, 2025 · Integrated sensor technology enhances the performance, safety, and efficiency of EV battery packs and cell connection systems – key

Li Ion Battery Pack Circuit Diagram – Wiring Flow

A Li-Ion battery pack circuit diagram is a visual representation of the individual cells and their interconnections within the battery pack. The diagram shows

Lithium Battery Terminals: A Comprehensive Guide

Learn about lithium battery terminals including button, stud, and bolt types, making connections, maintenance best practices, and how terminals differ

Understanding Battery Pack Technology: Key Components,

Mar 14, 2025 · Discover the essential aspects of battery pack technology, including key components such as cells, BMS, structural components, thermal management, production

Lithium-Ion Battery Pack Manufacturing Process

Jun 4, 2025 · These battery packs are critical components in electric vehicles (EVs), energy storage systems, and various portable electronic devices. Key

Lithium-ion Battery Internal Resistance Testing

What is internal resistance testing of lithium-ion batteries? Although batteries'' internal resistance would ideally be zero, internal resistance exists due to a variety of factors. Internal resistance

EV Lithium Battery PACK Design Process from

Mar 18, 2025 · EV Lithium Battery PACK Design Process: A Comprehensive Guide The design of Electric Vehicle (EV) lithium battery packs ⇱ is a complex

How to Build a Lithium Ion Battery Pack: Expert Guide for

Aug 1, 2025 · This technical guide examines the internal structure of lithium ion batteries and provides detailed procedures for constructing battery packs from individual components. The

How to Assemble a Lithium-Ion Battery Pack

Oct 7, 2024 · Learn how to safely assemble a battery pack with a BMS module. Our step-by-step guide covers materials needed, safety precautions, detailed

How to Assemble a Lithium Battery Pack: Step-by-Step

Feb 9, 2025 · By following this step-by-step guide, you can create a safe, efficient, and high-performance battery pack for your specific application. At NPP Lithium, we provide high-quality

6 FAQs about [Lithium battery pack internal connection solution]

What is a battery pack external communication interface?

ection applications within the battery pack. As a result, Molex has launched connection solutions dedicated to battery pack connectivity, helping o ATTERY PACK EXTERNAL COMMUNICATION INTERFACEThe battery pack external communication interface is for the battery management unit (BMU) to communicate with devices such as the vehicle control u

How does interconnection affect the performance of a battery pack?

Interconnection of the battery cells creates an electrical and mechanical connection, which can be realised by means of different joining technologies. The adaption of different joining technologies greatly influences the central characteristics of the battery pack in terms of battery performance, capacity and lifetime.

What is a Li-ion battery pack?

At the base of every Li-ion battery pack is the battery cell or cells. A pack can contain one cell or many cells configured to achieve higher capacity or output voltage. This is achieved by connecting cells in parallel or series, and we’ll explore this much further in our next blog.

What is a lithium battery management system (BMS)?

The cells within a lithium battery pack are typically arranged in series or parallel configurations to achieve the desired voltage and capacity. Additionally, a Battery Management System (BMS) is often integrated to monitor and ensure the safe operation of the battery pack.

What is a custom battery pack with connector?

Custom battery pack with connector. For lead acid batteries or battery types used for heavy-duty applications such as automotive, industrial machinery, or marine systems, battery terminal connectors are commonly used for these applications.

What is a safety circuit in a Li-ion battery pack?

Fig. 1 is a block diagram of circuitry in a typical Li-ion battery pack. It shows an example of a safety protection circuit for the Li-ion cells and a gas gauge (capacity measuring device). The safety circuitry includes a Li-ion protector that controls back-to-back FET switches. These switches can be

Industry Information

- Manama Energy Storage Container Customization

- Micro flywheel energy storage system

- Brunei user-side industrial and commercial energy storage solution

- Base station wind power cabinet battery

- Factory price 15kv switchgear in Canberra

- Main circuit breaker factory in Burundi

- Huawei Panama Colon Large Energy Storage Cabinet Wholesaler

- What are the energy storage power sources for 15 kWh of electricity

- Huawei large ups uninterruptible power supply

- Praia s new solar photovoltaic panels

- What is the energy storage battery manufacturer in Brazil

- Single-sided and double-sided types of photovoltaic modules

- Dushanbe aluminum alloy battery energy storage container sales

- EU TCL solar photovoltaic panels

- Liquid flow zinc energy storage battery

- 540w photovoltaic panel export manufacturer

- Photovoltaic container inverter

- Inverter battery pack charging

- Best high quality voltage breaker distributor

- Mobile power portability recommendation

- How to choose a container generator

- How many watts does the Nanya solar street light have

- Israel wall mounted inverter custom manufacturer

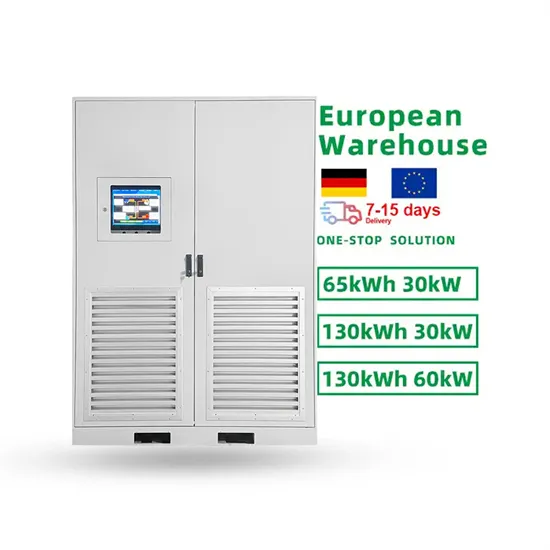

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.