Status and perspectives of crystalline silicon photovoltaics in

Mar 7, 2022 · Crystalline silicon solar cells are today''s main photovoltaic technology, enabling the production of electricity with minimal carbon emissions and at an unprecedented low cost. This

Upcycling of silicon scrap collected from photovoltaic cell

Jan 1, 2023 · Upcycling of silicon scrap collected from photovoltaic cell manufacturing process for lithium-ion batteries via transferred arc thermal plasma

Recovery of Nano-Structured Silicon from End-Of-Life Photovoltaic

Mar 27, 2020 · Herein, we demonstrate a potential end-of-life management option for photovoltaic (PV) panels, representing a step towards producing greener and more energy-efficient Si for

Recycling silicon photovoltaic cells into silicon anodes for Li

Sustainability spotlight The growing amount of solar photovoltaic module waste poses significant environmental and economic concerns. This research addresses the challenge through

$2.8M USDOE funding for project that would recycle silicon

Sep 2, 2023 · A US consortium is investigating recycling silicon wafers from PV panels for use in batteries for electric vehicles, claiming the recycled material can also cut battery costs, and the

ORBi: Detailed Reference

Jul 16, 2025 · Recovery of Nano-Structured Silicon from End-of-Life Photovoltaic Wafers with Value-Added Applications in Lithium-Ion Battery Eshraghi, Nicolas; Berardo, Loris;

Manufacturing lithium-ion anodes from silicon recovered

Feb 15, 2025 · Recycled photovoltaic silicon materials from waste solar cells are transformed into silicon carbon anodes for lithium-ion batteries using experimental techniques such as chemical

Single-reagent tech to reuse silicon from end-of

Sep 14, 2023 · Scientists in Singapore developed a single-reagent approach to recover silicon in recycled PV panels that reportedly offers high recovery rates

Recovery of Nano-Structured Silicon from End-of-Life Photovoltaic

Subscriber access provided by University of Massachusetts Amherst Libraries Article Recovery of Nano-Structured Silicon from End-Of-Life Photovoltaic Wafers with Value-Added Applications

Recovery of Nano-Structured Silicon from End-of-Life

Apr 23, 2020 · Recovery of Nano-Structured Silicon from End-of-Life Photovoltaic Wafers with Value-Added Applications in Lithium-Ion Battery,ACS Sustainable Chemistry & Engineering -

Next-Gen Lithium Batteries Born from Discarded

Jul 29, 2024 · Researchers have found groundbreaking ways to extract silicon from old solar panels, creating high-performance silicon battery anodes. When

Photovoltaic silicon wafers and battery components

Recovery of Nano-Structured Silicon from End-of-Life Photovoltaic Wafers with Value-Added Applications in Lithium-Ion Battery Millions of residential and industrial solar panels installed in

Recycling of photovoltaic silicon waste for high-performance

Aug 1, 2021 · To summarize, we have developed a method for recycling silicon waste from the photovoltaic industry to prepare silicon/graphite anodes for lithium-ion batteries.

Scientists develop new method to recover high-purity silicon

Sep 7, 2023 · Scientists have devised an efficient method of recovering high-purity silicon from expired solar panels to produce lithium-ion batteries that could help meet the increasing global

Silicon wafers for solar photovoltaic panels

About Silicon wafers for solar photovoltaic panels In the PV industry, the production chain from quartz to solar cells usually involves 3 major types of companies focusing on all or only parts

Upcycling Photovoltaic Silicon Waste Into Cost‐Effectiveness

Apr 27, 2025 · While silicon/carbon (Si/C) is considered one of the most promising anode materials for the next generation of high-energy lithium-ion batteries (LIBs), the

Recycling Silicon Cutting Waste from

Sep 6, 2024 · This study presents a novel approach for the fabrication of a composite material comprising SCW-derived silicon nanoparticles (SiNPs) and

End‐of‐Life Photovoltaic Recycled Silicon: A

May 5, 2021 · Advanced repurpose processes are developed to turn photovoltaic (PV) waste into the high-value circular energy materials. By recycling silicon

The research progress on recycling and resource utilization

Jun 15, 2024 · While recycling intact silicon wafers for the production of regenerated batteries presents operational challenges, processed silicon fragments, after etching and cleaning

Recovery of porous silicon from waste crystalline silicon solar panels

Nov 1, 2021 · A low-cost and easy-available silicon (Si) feedstock is of great significance for developing high-performance lithium-ion battery (LIB) anode materials. Herein, we employ

Recovery of Nano-Structured Silicon from End

Research ArticleMarch 27, 2020 Recovery of Nano-Structured Silicon from End-of-Life Photovoltaic Wafers with Value-Added Applications in Lithium-Ion

Recovery of Nano-Structured Silicon from End-of-Life

Apr 23, 2020 · Recovery of Nano-Structured Silicon from End-of-Life Photovoltaic Wafers with Value-Added Applications in Lithium-Ion Battery ACS Sustainable Chemistry & Engineering (

Recovery of Nano-Structured Silicon from End-of-Life Photovoltaic

Mar 27, 2020 · Recovery of Nano-Structured Silicon from End-of-Life Photovoltaic Wafers with Value-Added Applications in Lithium-Ion Battery

(PDF) Creating value added nano silicon anodes

May 15, 2024 · Recovery of silicon from end-of-life photovoltaic (PV) modules, purification, conversion to nano silicon (nano-Si), and subsequent application

What is Wafer in PV?

Nov 17, 2023 · The solar battery has both crystal and non-crystal battery types. Importance of Silicon Wafer Silicon is one of the most abundantly found

Endâ ofâ Life Photovoltaic Recycled Silicon: A

Nov 24, 2021 · One cannot claim solar panels to be recyclable, in a circular economy sense, until scientists find a way to harvest and repurpose their most valuable components, and silicon is

Advancing sustainable end-of-life strategies for photovoltaic

Jan 22, 2024 · Thus, it is necessary to explore new applications for recovered silicon, like its use as anode materials for lithium-ion batteries (LIBs). Although this alternative avenue has

Are silicon wafers photovoltaic panels

By interacting with our online customer service, you''ll gain a deep understanding of the various Are silicon wafers photovoltaic panels featured in our extensive catalog, such as high

Recovery of Nano-Structured Silicon from End-of-Life Photovoltaic

Recovery of Nano-Structured Silicon from End-of-Life Photovoltaic Wafers with Value-Added Applications in Lithium-Ion BatteryMillions of residential and industrial solar panels installed in

Recovery of porous silicon from waste crystalline silicon solar panels

Nov 1, 2021 · Herein, we employ waste crystalline Si solar panels as silicon raw materials, and transform micro-sized Si (m-Si) into porous Si (p-Si) by an alloying/dealloying approach in

Reusing silicon from end-of-life photovoltaic

Jul 14, 2023 · Reusing silicon from end-of-life photovoltaic modules for battery anodes Scientists in China have proposed to use recycled silicon from

Recovery of Nano-Structured Silicon from End-of-Life Photovoltaic

Apr 8, 2020 · The foreseen crisis, however, can be turned into a great opportunity by value-added recovery of precious solar-grade silicon (Si) to the highly desired nanostructured silicon for

Recovery of Nano-Structured Silicon from End-of-Life Photovoltaic

Mar 27, 2020 · Recovery of Nano-Structured Silicon from End-of-Life Photovoltaic Wafers with Value-Added Applications in Lithium-Ion Battery | ACS Sustainable Chemistry & Engineering

6 FAQs about [Photovoltaic panels silicon wafers lithium batteries]

Are recycled silicon wafers suitable for solar cells?

The photovoltaic (PV) industry uses high-quality silicon wafers for the fabrication of solar cells. PV recycled silicon, however, is not suitable for any application without further purification, as it contains various impurities.

Can solar panels be recycled for lithium-ion batteries?

The innovative upcycling of waste solar panel silicon for lithium-ion batteries (LIBs) presents a compelling avenue to address these multifaceted challenges, highlighting the critical role of interdisciplinary collaboration and technological ingenuity in steering society toward a more sustainable trajectory.

Can waste solar panel silicon be used for LIBS?

The upcycling of waste solar panel silicon for LIBs has the potential to intertwine the supply chains of solar cells and LIBs. Consequently, it is imperative to enhance collaboration among stakeholders to facilitate the industrialization and scalability of this strategy.

What is crystalline silicon based PV industry?

Considering the wastes of silicon (Si) resources, silicon-based PV industry could be the biggest one, particularly crystalline silicon (c-Si) PV module (0.67 kg Si/module), which occupies over 93% of the total production. Among various parts of the PV module, PV cell is the most important part, which uses high-quality silicon wafers.

Can silicon be used as an anode in lithium-ion batteries?

Silicon is incredibly versatile, yet its high-value applications, such as semiconductors, generally demand the same stringent purity levels. 7 However, a promising avenue appears to be its use as an anode material in lithium-ion batteries (LIBs), which doesn't stipulate such high purity requirements.

Are solar panels recyclable?

Research data are not shared. One cannot claim solar panels to be recyclable, in a circular economy sense, until scientists find a way to harvest and repurpose their most valuable components, and silicon is one of them. The photovoltaic (PV) industry uses high-quality silicon wafers for the fabrication of solar cells.

Industry Information

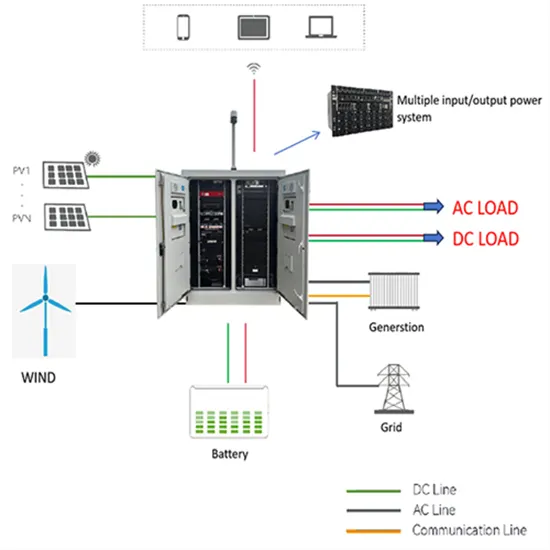

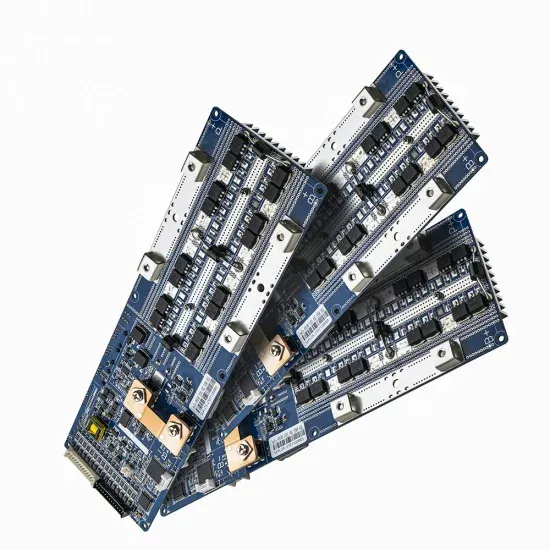

- Internal structure of PCS for energy storage system grid connection

- Best inverter manufacturer in Nicosia

- Single phase H-bridge inverter price

- PV Energy Storage EPC Price

- Kampala water pump solar energy

- Georgia Telecommunication Base Station Wind Power Government Document

- What is the cas number of the uninterruptible power supply

- Buy a new 200kw solar power system

- Outdoor power supply with lighting

- Ashgabat industrial frequency ups uninterruptible power supply equipment

- Inverter 48v for communication

- Wholesale transformer breaker in Atlanta

- Wholesale 2 breaker sub panel in Lisbon

- Brazil standard photovoltaic module prices

- Energy storage power supply profit

- 10kw grid-connected inverter

- Sucre Peak Shaving and Valley Filling Energy Storage Battery

- 5kva inverter system in China in Ukraine

- Imported medical isolation uninterruptible power supply

- Valletta construction site photovoltaic folding container wholesale

- Uzbekistan distributed intelligent energy storage project approved

- Isolation method of photovoltaic inverter

- BMS battery development prospects

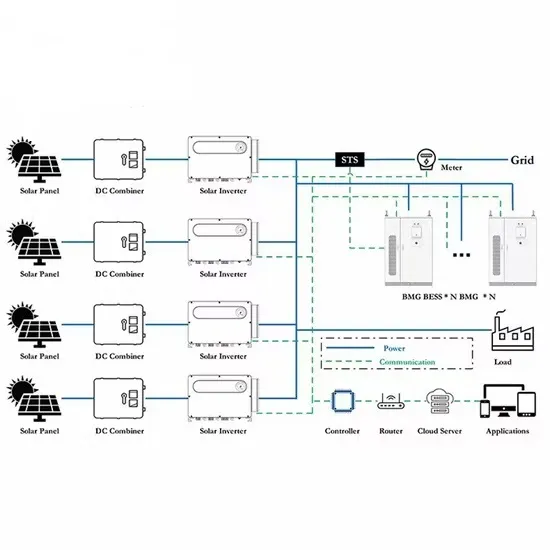

Commercial & Industrial Solar Storage Market Growth

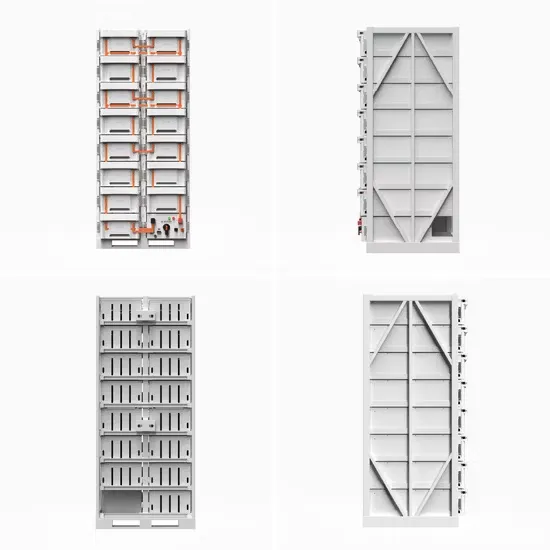

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.