Modeling, Development, and Validation of Battery

6 days ago · The market of electric vehicles (EVs) is growing day by day due to their environmentally friendly operation. The Battery Management Systems (BMS) is the heart of

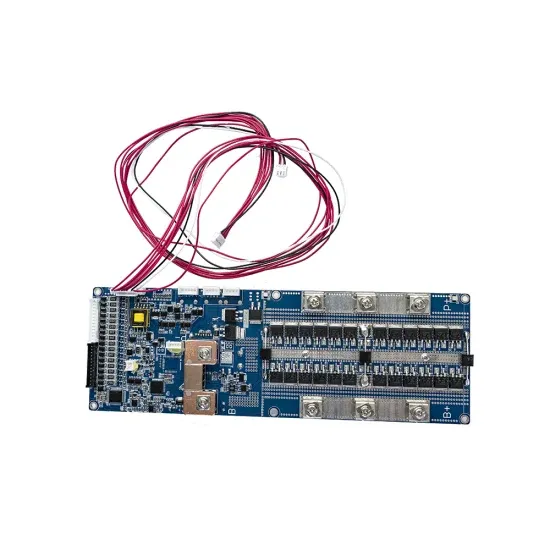

DALYBT 24S LFP 60A Smart BMS

DALYBT 24S LFP 60A optimize the performance of the battery over its entire life (such as monitoring of state of charge and state of health).

72V 200Ah EV Lithium Battery Pack

4 days ago · LifePO4 Battery 72V 200ah JMH 72V 200Ah, this battery is designed for electric vehicles, composed of lithium iron phosphate cells. The

DALYBT 21S LI-ION 80A Smart BMS

Apr 19, 2025 · DALYBT 21S LI-ION 80A optimize the performance of the battery over its entire life (such as monitoring of state of charge and state of health).

72V 100ah 150ah 200ah Lithium Battery with Smart BMS 7kw

Aug 13, 2025 · 72V 100ah 150ah 200ah Lithium Battery with Smart BMS 7kw 10kw 15kw Battery Pack for Low-Speed Car, Find Details and Price about 72V Battery Pack 72V Lithium Batteries

Daly 24S 72V 30A LifePo4 Battery Balanced BMS

DALY BMS 24S 72V LifePO4 PCB Protection Board with Balance Wire and Temperature Sensor for 24 3.2V Cells 72V LiFePO4 Lithium Battery Pack with

Complete Guide: 12V/24V/48V/72V Batteries,

Jul 19, 2025 · With the rapid development of new energy technologies, lithium batteries—especially 12V, 24V, 48V, and 72V variants—as well as LiFePO4

EBike Battery

This category includes 12V~72V Li-Ion/LiFePO4 EBike battery packs and cells, E-Bike bottle battery, high power battery and high C-Rate cells, 4~24 cells in

Battery Management System For Electric Vehicle:

Mar 24, 2025 · Battery Management System For Electric Vehicle: How It Works & Why It''s Essential What Is Battery Management System (BMS)? A Battery

72V Lithium-ion Battery

Our 72V Lithium-ion Battery is designed for a range of applications including electric motorcycles, electric skateboards, hoverboards, and golf carts. Available in sturdy steel or aluminum alloy

72V Lithium Batteries: Ultimate Guide

Explore 72V Lithium Batteries: uncover their benefits, applications, and chemistry comparisons. Learn how to choose the best supplier.

72V 30Ah LiFePO4 Lithium Battery

LYBATT''s 72V 30Ah deep-cycle LiFePO4 lithium battery can be used for electric motorcycles and electric bicycles. It has high-quality top-quality cells, built-in BMS, and long service life.

Development of Battery Management System

Jun 19, 2024 · In order to prevent a fire hazard from the lithium-ion battery, the design concept of the uni-versal BMS PF defines its main function (MF) as "controlling the charged/discharged

72V Lithium Battery BMS Development Key Insights for High

May 20, 2025 · Understanding the Importance of BMS in 72V Lithium Batteries When it comes to 72V lithium battery BMS development, the Battery Management System (BMS) acts as the

BMS Development | BMS Solutions

Re:Build Battery Solutions develops advanced Battery Management Systems (BMS) engineered to optimize performance, safety, and efficiency for lithium-ion battery packs across a wide

Best BMS for Lithium and Lifepo4 Battery Packs

May 9, 2023 · Looking for the best BMS for your lithium battery build? Look no further we tested and tried them all!

How To Choose A BMS For Lithium Batteries

Aug 22, 2022 · When choosing a BMS for a lithium-ion battery, the most important aspects to consider is the maximum current rating and that the BMS

LFP battery BMS 72V 50A

Sep 7, 2021 · Discover the LFP Battery BMS 72V 50A, designed to provide exceptional performance and protection for 72V lithium ferrophosphate

How does lithium battery BMS determine the

May 1, 2025 · To ensure the safe, stable, and efficient operation of battery packs, the Battery Management System (BMS) was developed, becoming an

Development and Evaluation of an Advanced Battery

Sep 22, 2024 · This paper presents the development and evaluation of a Battery Management System (BMS) designed for renewable energy storage systems utilizing Lithium-ion batt

DALY Smart BMS Li-ion 20S 72V 100A common

6 days ago · The DALY Smart Battery Management System (BMS) is designed for lithium-ion battery packs in a 20S configuration, offering robust

Battery Management Systems | Lithium BMS

Lithium-ion applications come with pretty unique electrical demands. That''s why a one-size-fits-all battery management system simply won''t cut it. Voltaplex

What Is a 72V Battery Pack? Uses & Benefits Explained

Jun 1, 2025 · What defines a 72V battery system? A 72V system combines lithium-ion cells in series to achieve 72V nominal voltage. It includes a Battery Management System (BMS) for

American Electric BMS 72V 20S 100A Li-Ion

Need a custom Battery Management System (BMS) ? Protect and empower your batteries with an American Electric Hardware or Bluetooth BMS! Optimize

72V 40Ah Lithium Battery | Wholesale Ebike

MANLY Battery offers reliable 72V 40Ah Lithium Battery. This 72V battery provides bulk savings and customization as a top wholesale ebike battery choice.

Daly Lfp Bms Bike Lithium Lifepo4 Electric Vehicle Battery

Daly Lfp Bms Bike Lithium Lifepo4 Electric Vehicle Battery 23S 24S 72V 200A offers overcharge, overcurrent, and short-circuit protection. Perfect for EVs.| Alibaba

Modeling, Development, and Validation of Battery

6 days ago · This paper employs a simulation of a 20-cell lithium-ion battery pack (72V, 2.9Ah) where Coulomb Counting achieves real-time SOC estimation accuracy under defined test

Amarakosha Technologies

Advanced Battery Solutions for Reliable Performance. Our Automotive 72V Integrated Battery Management System (BMS) is designed for high-performance lithium-ion battery systems,

72V Lithium Battery BMS Development Key Insights for High

May 20, 2025 · From enhancing EV range to stabilizing renewable grids, 72V lithium battery BMS development remains pivotal across industries. As wireless technologies and AI integration

foxBMS – The Most Advanced Open Source BMS

foxBMS is a free, open and flexible research and development environment for the design of Battery Management Systems (BMS). Above all, it is the first

Battery Management System (BMS): The

Therefore, nearly all lithium batteries on the market need to design a lithium battery management system. to ensure proper charging and discharging for

Battery Management System

Protection during charging and discharging with additional functions to lengthen battery lifetime, favorable and reliable Battery Management Systems for

What Happens If the Lithium-ion Battery Gets Wet?

Lithium-ion batteries power everything from smartphones to electric vehicles, but what happens when the lithium-ion battery gets wet? Water exposure risks short circuits, chemical reactions,

6 FAQs about [72V Lithium Battery BMS Development]

What is lithium battery management system (BMS)?

To ensure the safe, stable, and efficient operation of battery packs, the Battery Management System (BMS) was developed, becoming an indispensable core component in lithium battery systems. This article will explore the functions, working principles, application areas, future development trends, and challenges of lithium battery BMS in depth.

Why do lithium batteries need a battery management system?

Therefore, nearly all lithium batteries on the market need to design a lithium battery management system. to ensure proper charging and discharging for long-term, reliable operation. A well-designed BMS, designed to be integrated into the battery pack design, enables monitoring of the entire battery pack. And greatly extend battery life.

What is a battery based monitoring system (BMS)?

BMS communicates with external devices (such as vehicle control units, charging stations, and monitoring systems) through communication interfaces such as CAN bus, LIN bus, or Ethernet, enabling real-time data exchange and system integration. Lithium battery BMS operates based on real-time monitoring and intelligent algorithm processing.

How does a battery BMS work?

Advanced BMS systems may also monitor parameters such as internal impedance and electrolyte concentration to more accurately assess battery status. Using collected data and advanced algorithm models (such as Kalman filtering and neural networks), lithium battery BMS accurately estimates the SOC and SOH of the battery pack.

What challenges does lithium battery BMS face?

Despite advancements, lithium battery BMS still faces challenges such as: High-Precision Sensors and Algorithms: Enhancing SOC, SOH, and RUL estimation accuracy. Real-Time Performance and Reliability: Ensuring rapid response to battery state changes. Cost and Compatibility: Addressing customization needs across different battery types.

Are lithium-ion batteries safe to use?

However, they have risks of re hazard and electric shock if being used incorrectly. In order to use the highly e cient lithium-ion batteries safely and e ectively, a battery management system (BMS) is needed. Among the BMS, technologies of the battery capacity estimation and the malfunction detection are important.

Industry Information

- How many kw does the inverter have

- Small solar monitoring power generation system in El Salvador

- 20w solar water pump for agricultural use

- Flywheel energy storage price

- What size inverter should be used with a 80a lithium battery

- Mobile outdoor power supply with solar

- Vietnam s new photovoltaic panel manufacturer

- Maputo high rate lithium battery pack

- Malabo s new solar power generation system

- Energy storage battery pack performance

- Smart 12V mobile inverter

- Integrated energy storage vehicle equipment

- Angola Large Industrial Park Energy Storage Cabinet

- Bamako Communications Branch 2MWH first 5G base station

- Mauritius Energy Storage Equipment

- Are energy storage batteries a good thing

- What are the outdoor power supplies in Antwerp Belgium

- Libya reinstalls outdoor power supply

- Eritrea Energy Storage Power Direct Sales Store

- Base station wind power battery

- Dual circuit breaker for sale in Kuwait

- Huawei Equatorial Guinea photovoltaic module project

- Energy Storage Solar Brand New

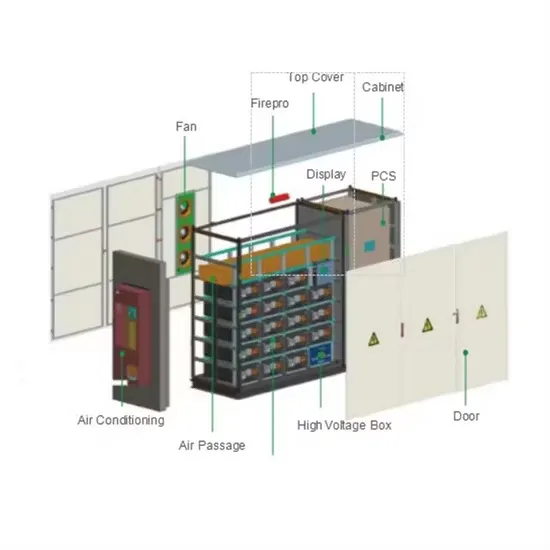

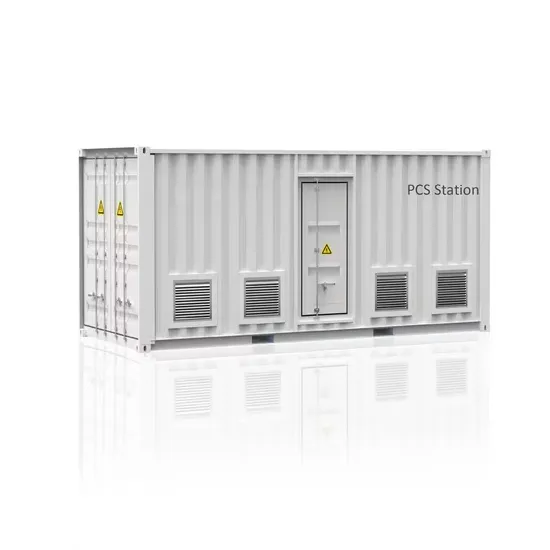

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.